EasyCoder PX4i and PX6i Service Manual 51

Chapter 7 — Transfer Ribbon Mechanism

7.2 Ribbon Supply Unit

Description

The ribbon supply unit is the same for EasyCoder PX4i and EasyCoder

PX6i with the exception of the strength of the spring in the spring brake.

It is used to accommodate the fresh supply of thermal transfer ribbon. For

optimum printout quality and trouble-free operation, only original transfer

ribbon from Intermec should be used.

The unit is designed to keep the ribbon tight all the time in order to avoid

wrinkling, which would ruin the printout. It consists of a shaft on which

a hub is fi tted. The hub can pivot ± 1.3° on the shaft and the hub can be

moved sideways between 6 fi xed positions.

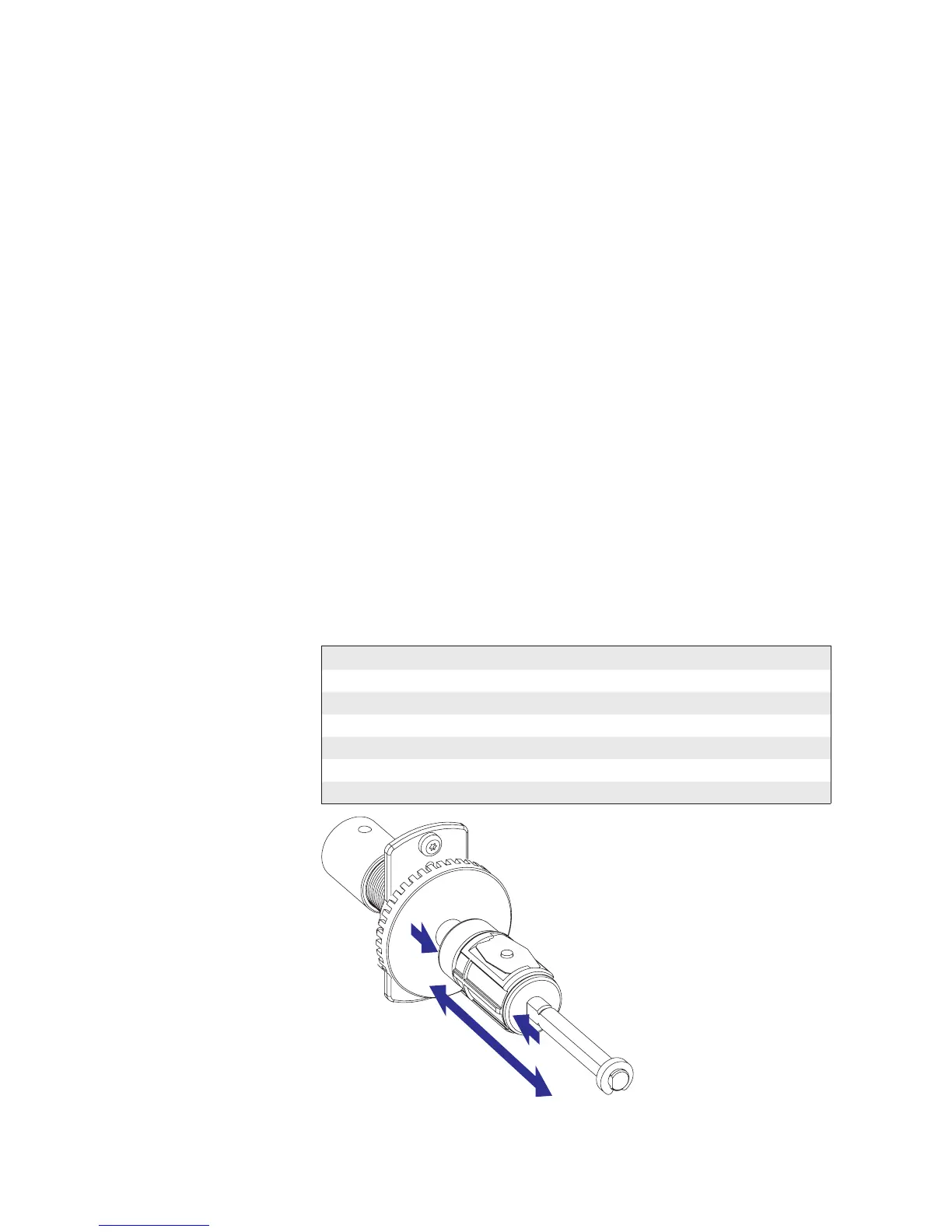

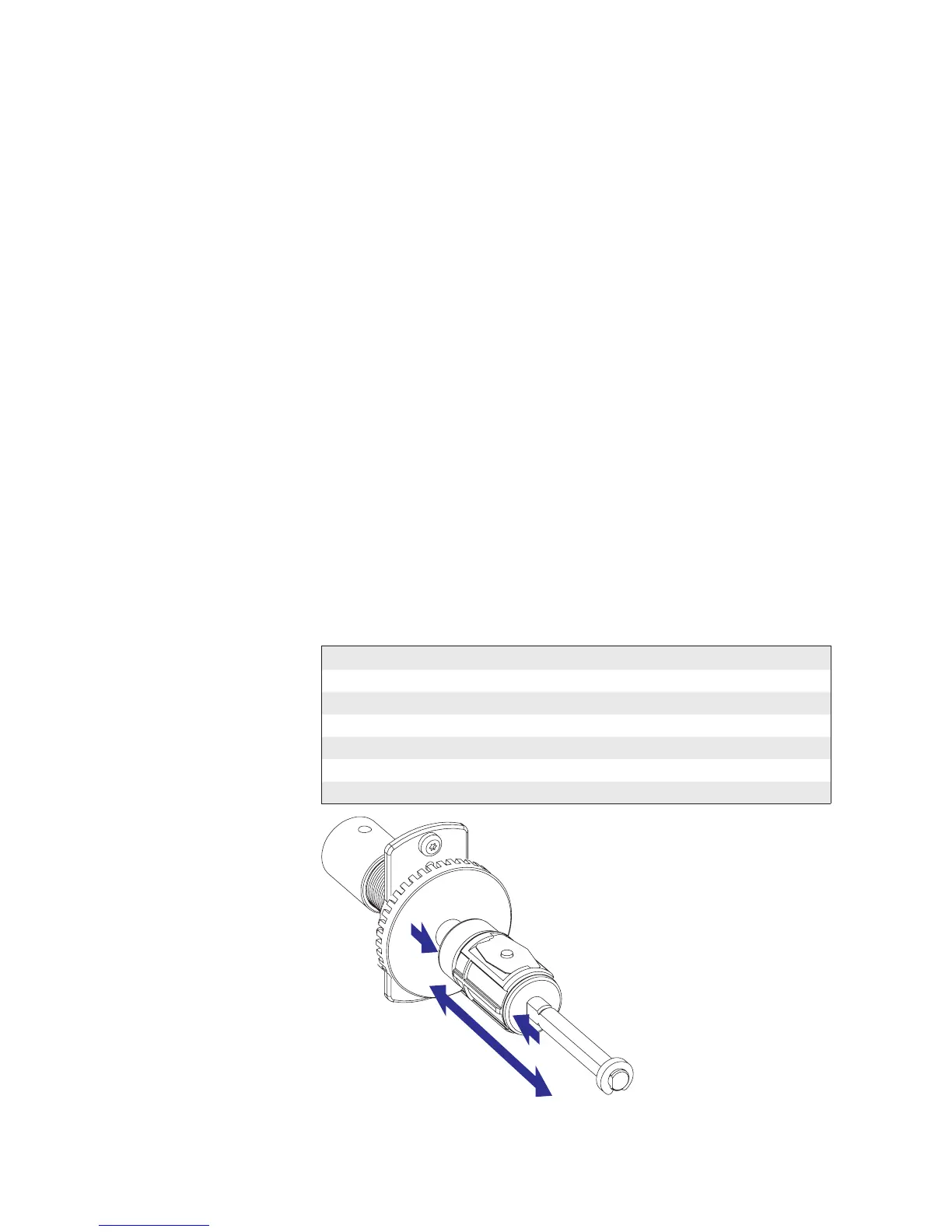

Adjustment

It is most important for avoiding ribbon wrinkling that the pivoting point

of the hub is centered in relation to the ribbon width. Therefore, the shaft

is provided with six grooves which correspond to the standard widths of

Intermec transfer ribbons (see table below). The three innermost grooves

are used with EasyCoder PX4i, whereas the three outermost grooves only

are used with the wider EasyCoder PX6i. By compressing the hub, its

snap-lock will disengage from the presently engaged groove and the hub

can be moved sideways to another position. Make sure that the snap-lock

has engaged a groove by trying to move the hub without compressing it.

Ribbons with a width less than 55 mm (2.16 inches) can be used provided

they are wound on a core with a width of at least 45 mm (1.77 inches).

Ribbon Width Position (groove) Note

55-60 mm (2.16-2.36 in) 1:st (innermost) PX4i only

88-90 mm (3.5 in) 2:nd All

110 mm (4.3 in) 3:rd All

130 mm (5.1 in) 4:th PX6i only

154 mm (6.0 in) 5:th PX6i only

≤ 166 mm (6.5 in) 6:th (outermost) PX6i only

Loading...

Loading...