5

Stop the main motor.

Leave the power switch turned on.

Observe the state of rod1 and rod 2.

while manually turning.

and move the knife to the top.

Turn the clutch key on.

Open the knife height adjustment window.

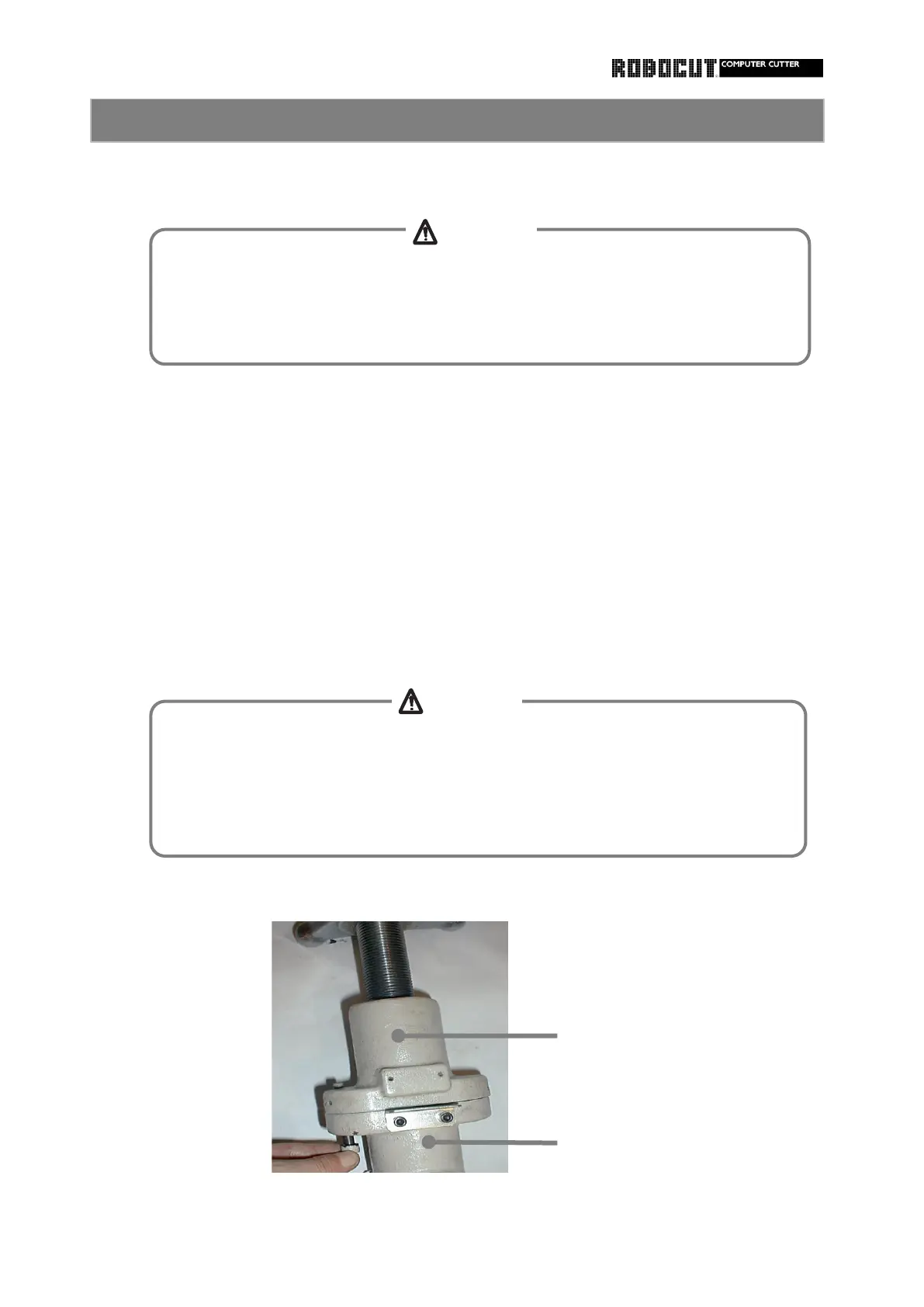

It is necessary to check if the joining face of rod1 and that of rod 2, which are separated

due to the broken safety bolt, is in parallel and check if they can be joined without a gap

According to circumstances of breakage of the safety bolt, rod 2 separated from rod 1

may face sideway or downward. Restoration in these xases is difficult and necessitates

replacement of a part ( insert rod ). Contact our service division.

Turn the clutch on with the clutch key and install a wrench at the end of the shaft located

on the right side face of the main body to move rod 1 and rod 2 close to each other and

join so that the safety bolt installation holes are aligned. Check if they are joined completely

How to replace the safety bolts 1

Turning the clutch key on releases the knife brake. Leave the clutch key turned off

unless the manual shaft is turned or held with a wrench.

Otherwise the knife will drop due to own weight and injuries will be caused.

Never reach beneath the knife.

Otherwise injuries will be caused.

The flywheel, pump pulley , V-belt and main motor pulley keep rotating due to inertia

for about 150 seconds after the main motor is stopped. Check for stoppage befor

continuing to work.

Otherwise entanglement and injuries will be caused.

Loading...

Loading...