Stop the main motor. Remove the strainer and clean it with

light oil. Install the strainer.

Clean the inside of the tank

Supply new oil up to the middle in the

oil gauge.

Install the lid of the oil tank.

Remove the lid of the oil tank.

Start the main motor and check the

movement of the clamp.

Use a siphon type manual pump or the

like to drain old oil.

When conducting inspection, maintenance or repairs, turn the curcuit breaker off, post

a " work under way " sign, post supporting workers and take other measures so that

another person will not turn the power on or start operation.

Otherwise injuries will be caused.

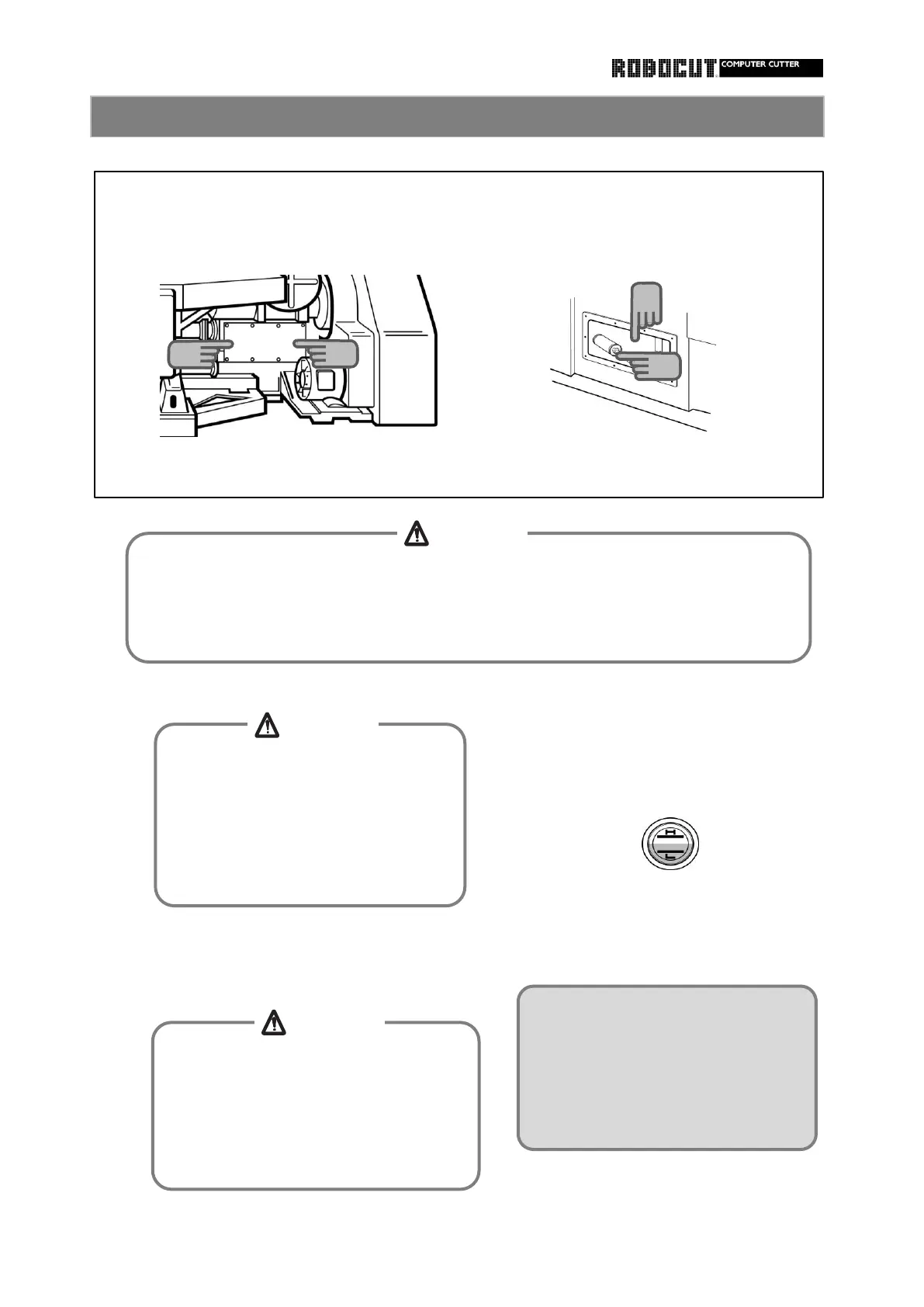

The flywheel,pump pulley, V-belt and

main motor pulley keep totating due

to inertia for about 150 seconds after

the main motor is stopped. Check for

stoppage.

Otherwise entanglement and injuries

will be caused.

When using an electric pump, be careful

to avoid entanglement. Oil may be hot

immediately after the main motor is

stopped. Wait until the oil temperature

lowers before working.

Otherwise injuries or burns will be caused.

A " jumping clamp " symptom is

caused by bubbles having entered

the hydraulic curcuit during oil change.

Repeat air cutting until bubbles are

eliminated and motion becomes

stabilized.

5

Loading...

Loading...