98

PR-23 instrucon manual

To ensure EHEDG compliant installation, follow the mounting speciics provided on

the mounting drawing supplied by K-Patents with each PR-23-AP refractometer or-

dered with the -EH option.

9.4.8 3A Sanitary Standard compliance

The user should ensure that the refractometer is not a source of contamination to

product due to damaged or worn product contact surfaces. Misuse (e.g. too long prism

wash time or too high wash pressure) or mishandling may result in metal scratches

or roughened surfaces. Such surfaces may not stay clean in processing.

K-Patents offers a 3A Sanitary Standard Accepted repair and maintenance package in

which all wetted parts, prism, gaskets and dryer are replaced. Note that this repair

service can be completed by 3A authorized service center only (K-Patents factory or

regional headquarters).

9.5 Compact process refractometer PR-23-GC

The K-Patents Compact process refractometer PR-23-GC is designed for the general

industry small pipeline and bypass line applications e.g. in chemical, oil, gas, petro-

chemical and kraft pulping processes.

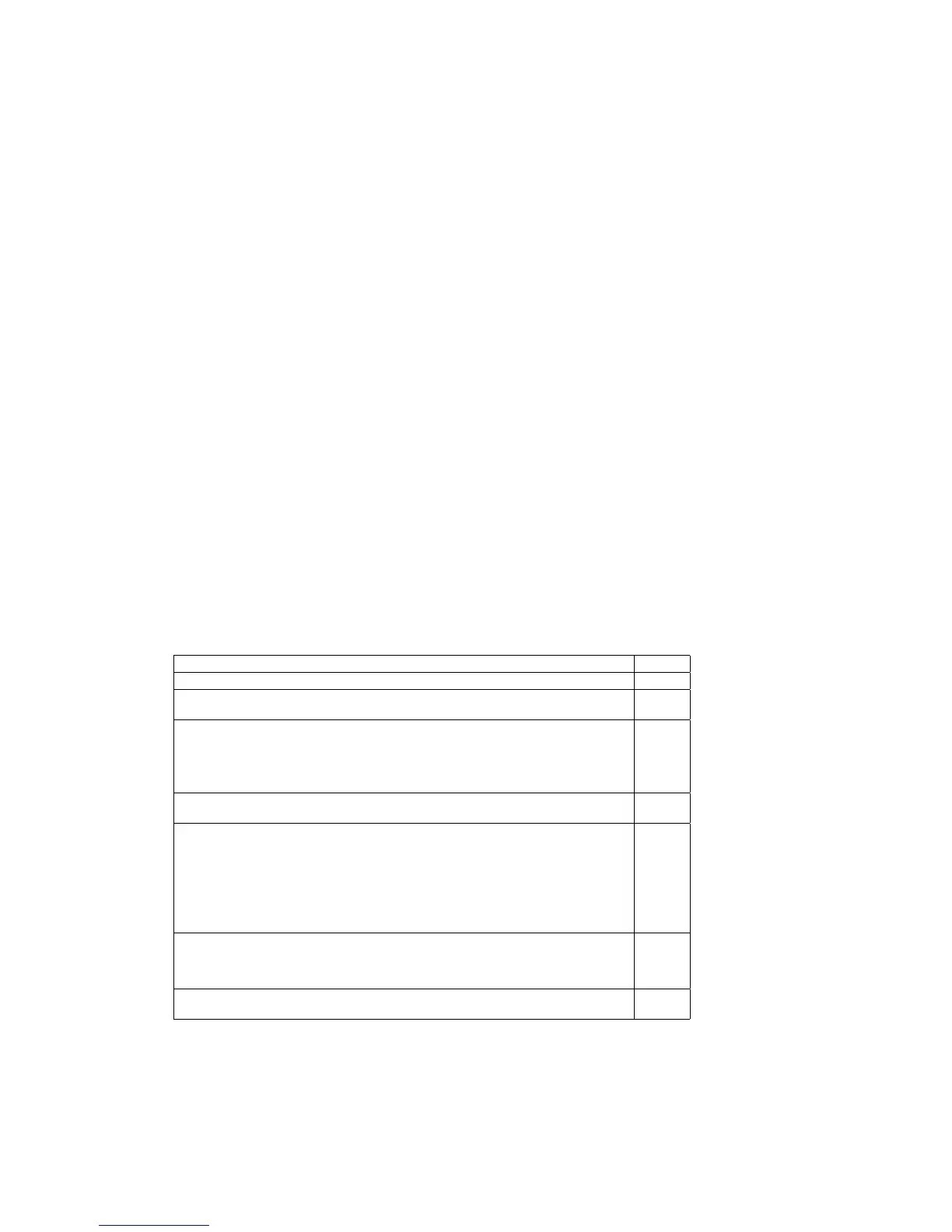

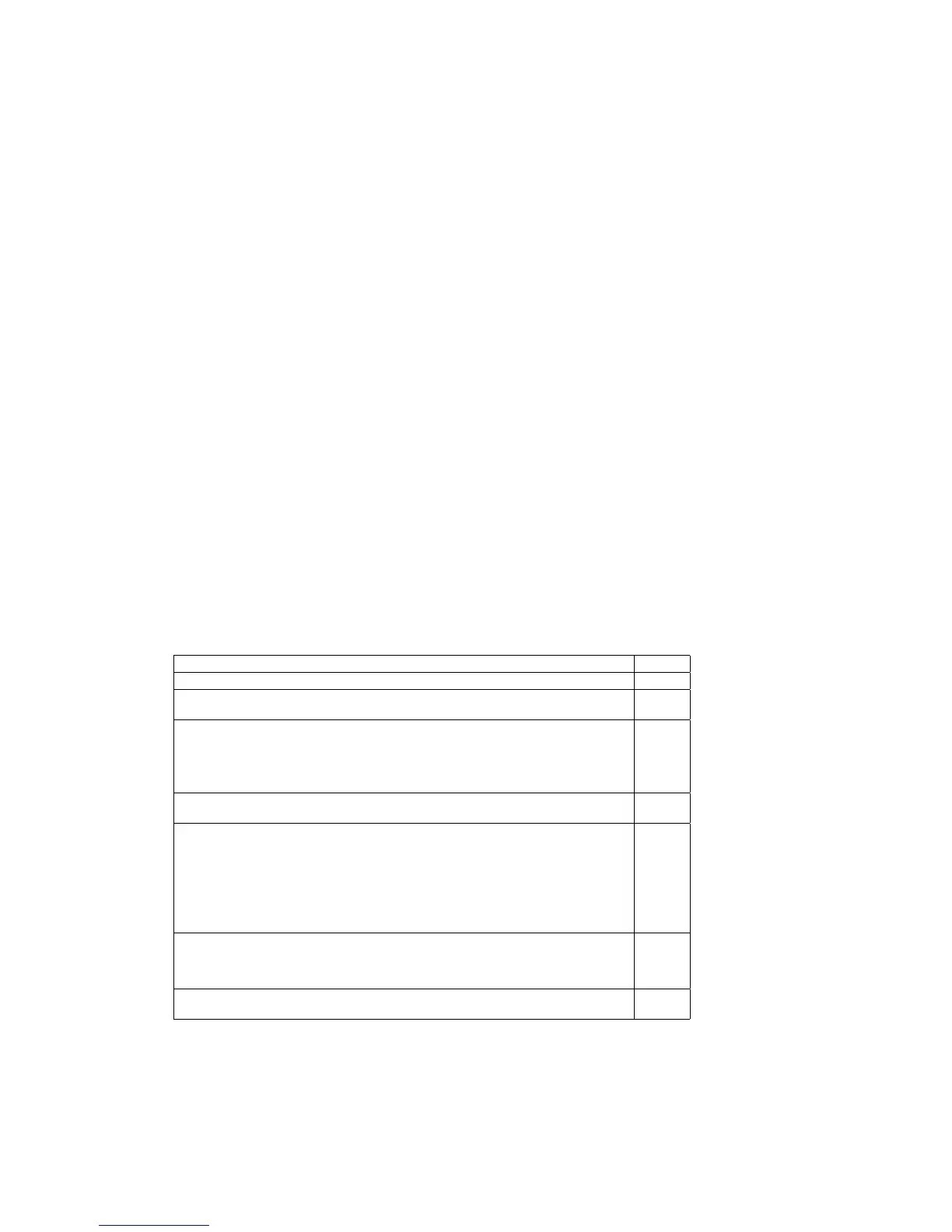

9.5.1 PR-23-GC sensor model code

MODEL AND DESCRIPTION MODEL

PR-23 = Sensor PR-23

Sensor model

-GC = General purpose compact -GC

Refracve Index range limits

-73 = n

D

1.320–1.530 (0–100 Brix) Sapphire prism -73

-74 = n

D

1.260–1.470, Sapphire prism (A) -74

-82 = n

D

1.410–1.620, YAG prism (A) -82

-92 = n

D

1.520–1.730, GGG prism (A) -92

Process connecon

-K = Sandvik L coupling 76.1, inseron length 12 mm -K

Sensor weed parts material

SS = AISI 316 L SS

HA = Alloy 20 HA

HC = Hastelloy C / ASTM C276 HC

NI = Nickel 200 NI

TI = Titanium ASTM B348 TI

SU = AISI 904L SU

XS = SAF2205 XS

Electrical classicaon

-GP = General Purpose -GP

-AX = ATEX cered EX II 3 G Eex nA II T4 (up to Zone 2) -AX

-IA = ATEX and IECEx cered EX II 1 G Ex ia II C T4 Ga (up to Zone 0) -IA

Sensor housing

-SC = Stainless steel AISI 316 -SC

Loading...

Loading...