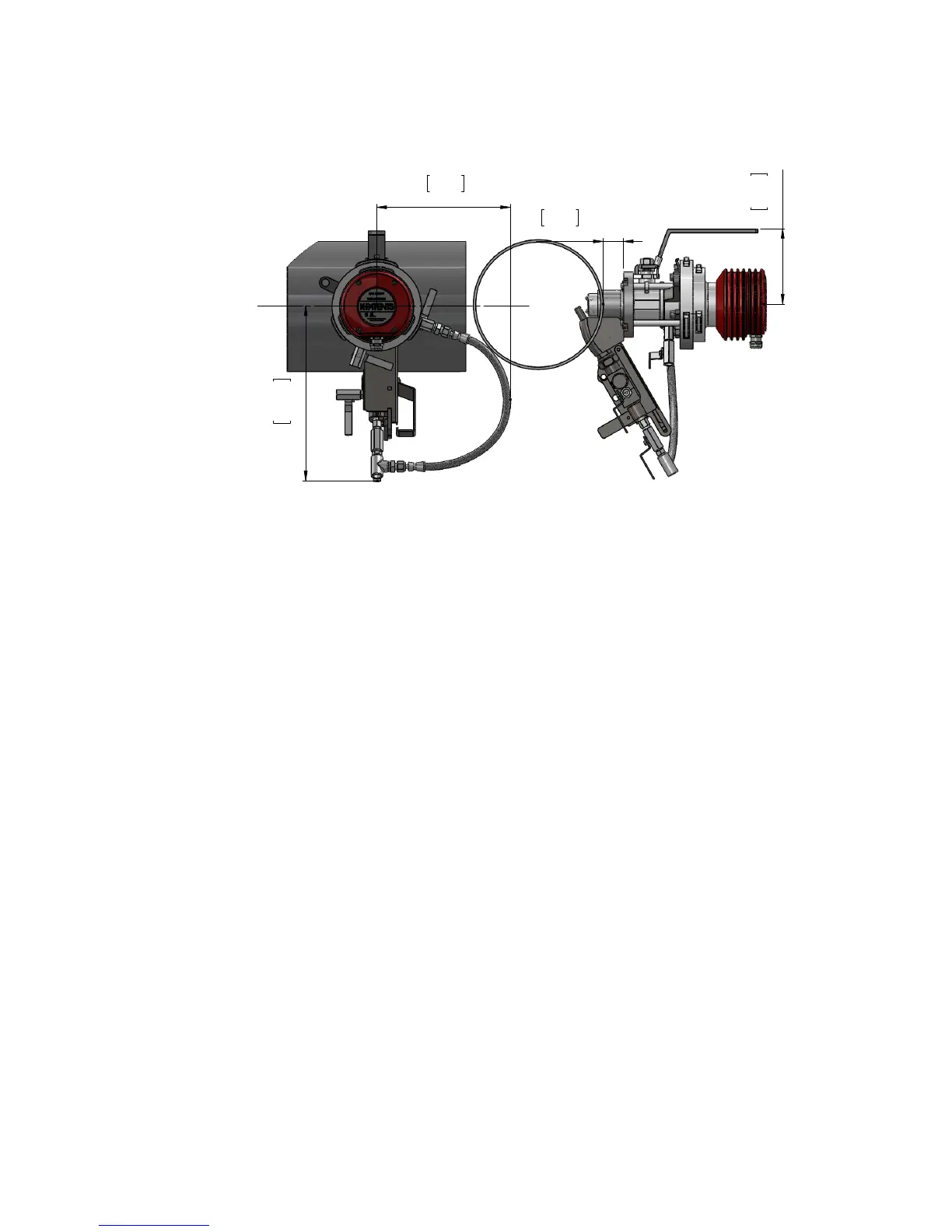

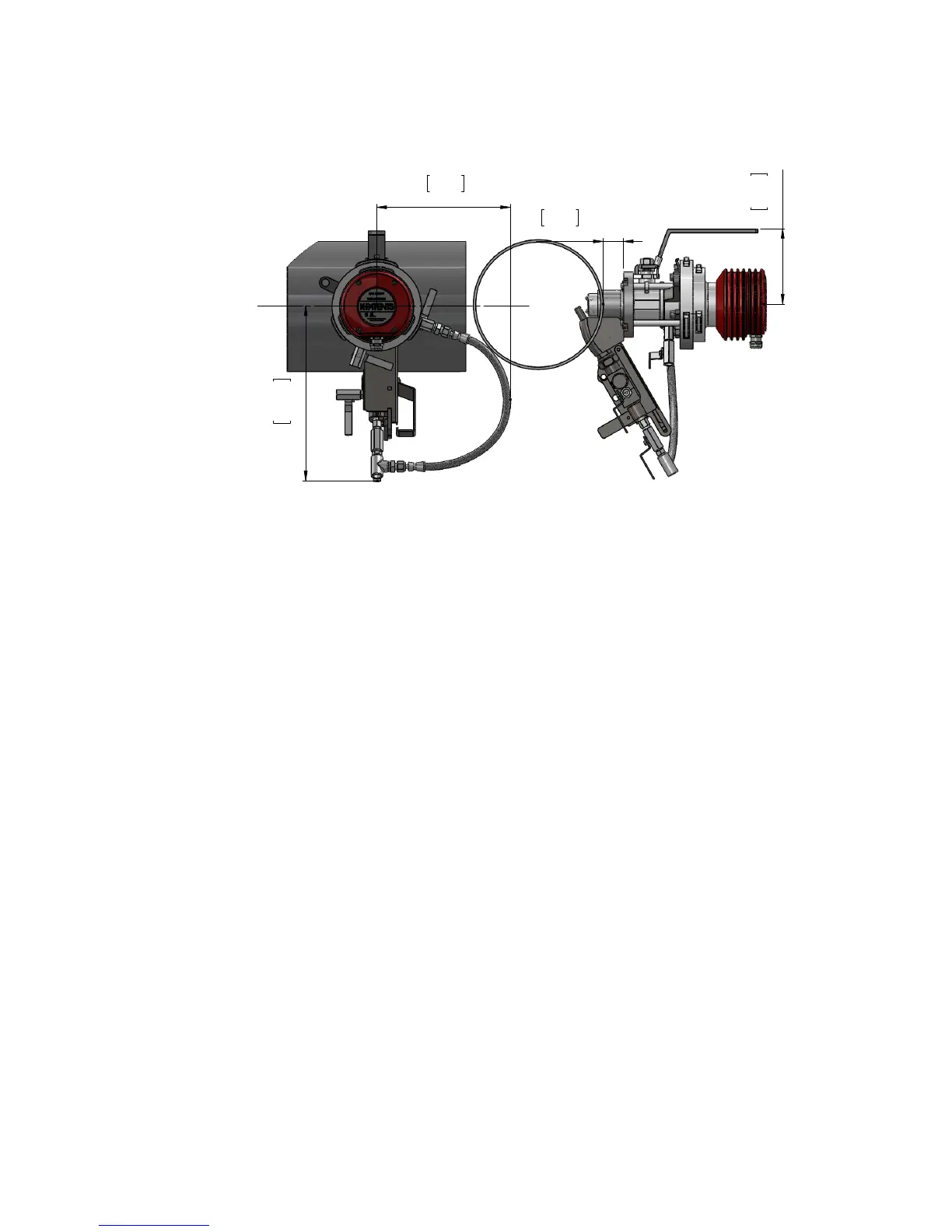

B

11.60

295

8.86

225

Side view

Top view

1.34

34

5.01

127

F

10.78

274

1.93

49

Related drawing.

No modification permitted

without the approval of

the authorized person.

500 - 1000 [2 - 3 ft]

1000 - 1500 [3 - 6 ft]

Floor or

working platform

Appr.

Drawn

Drawing number

Drawing description

Mass

General tolerances

MTG

27.09.2013 IA

-

Revision

2931

A

Scale

1:5

SDI2 horizontal pipe, space requirement

Material

31.01.2014 AHä

Figure 11.5 Mounng on a horizontal pipe

11.4.1 Welding isolaon valve to pipe

For the Safe-Drive™ Isolation valve, two holes – 50 mm (2") and 25 mm (1") – are

drilled to the pipe and the bridge between the holes is then removed. To help you place

the holes correctly, K-Patents delivers with the valve an installation guide sticker (see

Figure 11.6).

Welding steps (see Figure 11.7 or Figure 11.8):

1. Clean the surface of the pipe around the installation area and place the

guide sticker across the pipe. Make sure that the low marker is parallel

to the pipe and points to the correct low direction.

2. Disassemble the isolation valve for welding to avoid thermal damage to the

isolation valve sealing.

3. Drill 50mm(2") and 25mm (1") holes to pipe and cut the metal away be-

tween the holes.

4. Weld the isolation valve according to MTG472 or MTG2149 (Figure 11.7 or

Figure 11.8)

5. Reassemble the isolation valve. Note! The isolation valve handle and the

large bayonet tooth must be on the top.

6. Tighten the four M10 nuts to the correct torque.

Loading...

Loading...