42

PR-23 instrucon manual

6.2.3 Tolerance me

The tolerance time setting can be used in processes where there are intermittent

breaks in the measurement due to non-representative sample on the prism. This typ-

ically occurs when there are large voids in the process liquid.

If the optical image can be interpreted, the tolerance time setting does not have any

effect. When the optical image can no longer be interpreted (status messages, e.g.,

NO SAMPLE, NO OPTICAL IMAGE, PRISM COATED), the measurement is held for the given

number of seconds.

For example, a setting of 10 seconds ensures that any NO SAMPLE state which is shorter

that 10 seconds will not make a dip into the output signal. The factory setting is 5

seconds, access the 6 TOLERANCE TIME menu item to set the tolerance time.

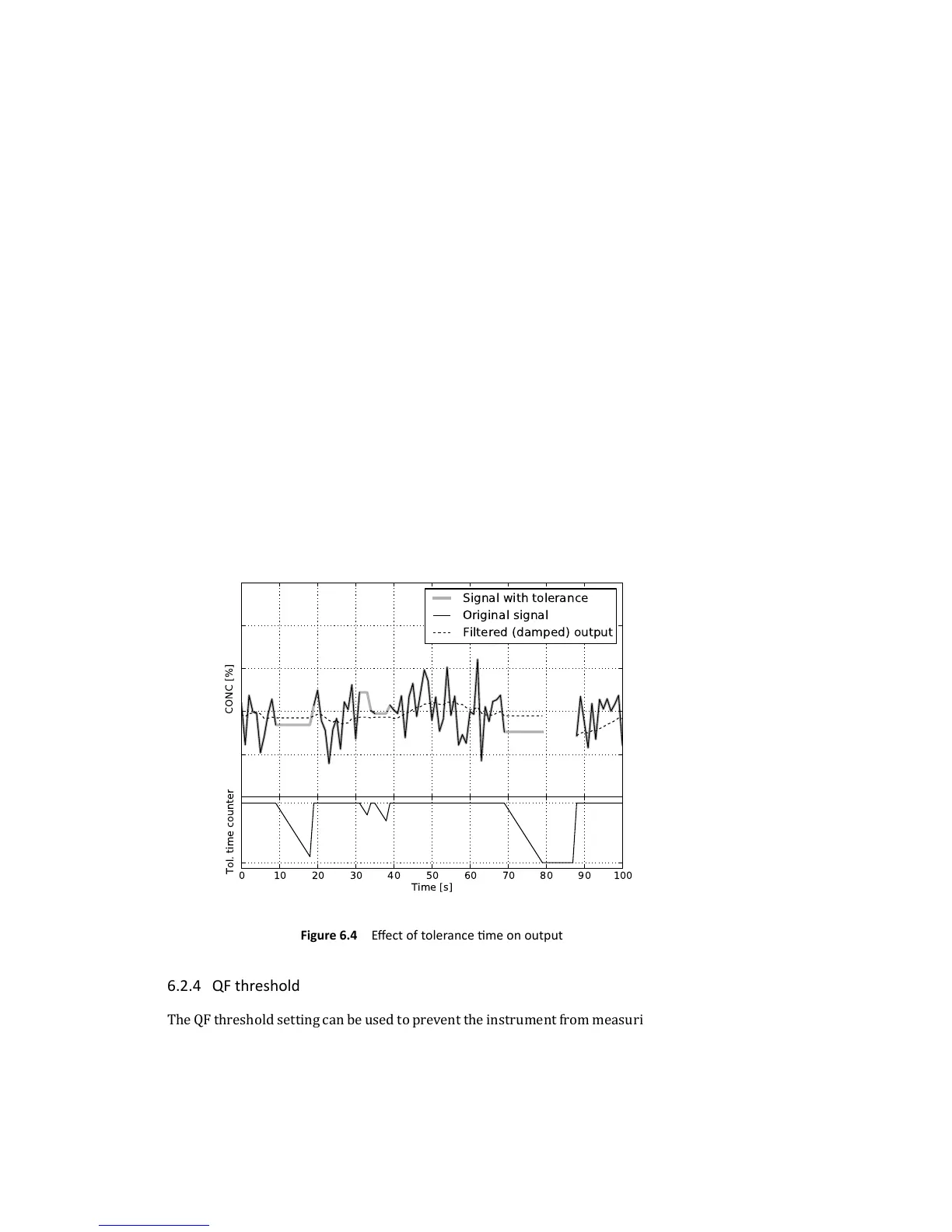

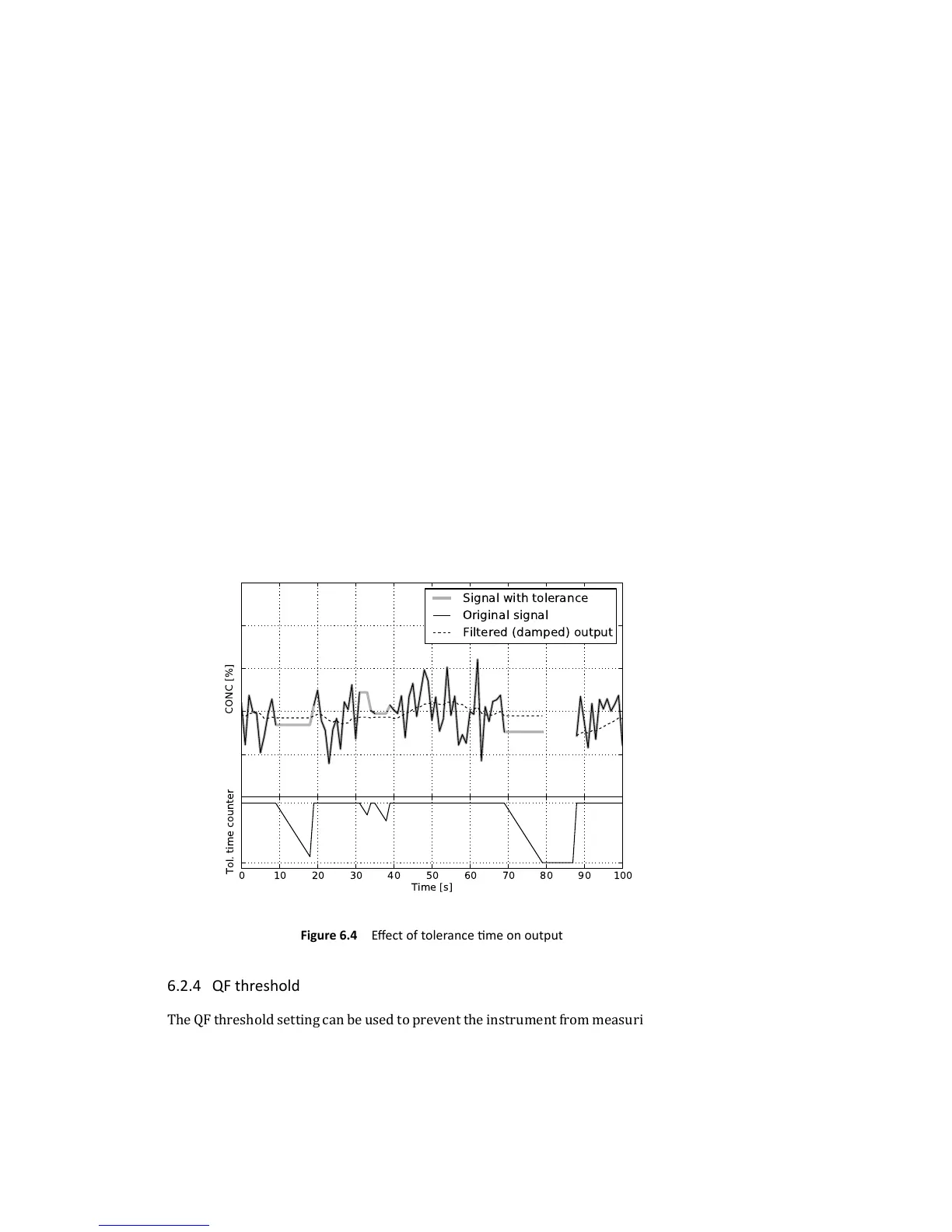

The tolerance time counter is reset always when there is a representative sample on

the prism (e.g., the nD can be determined). Figure 6.4 illustrates this behaviour with

an intermittent measurement signal. When the signal drop is shorter than the toler-

ance time (e.g. at t = 10 s or t = 35 s in the igure), the output signal does not drop. If

the signal drop is so long that the tolerance time counter reaches zero, there will be a

drop in the output signal (at t = 80 s in the igure)

Figure 6.4 Eect of tolerance me on output

6.2.4 QF threshold

The QF threshold setting can be used to prevent the instrument from measuring when

the image quality is below a certain limiting value. When QF value becomes less than

the user deined value the image status changes to NO OPTICAL IMAGE after the user

Loading...

Loading...