48

PR-23 instrucon manual

− First select 5 CALIBRATION in the Main menu and enter password if necessary.

Then select 2 OUTPUTS in the Calibration menu. In the Outputs menu, select 5 mA

OUTPUTS.

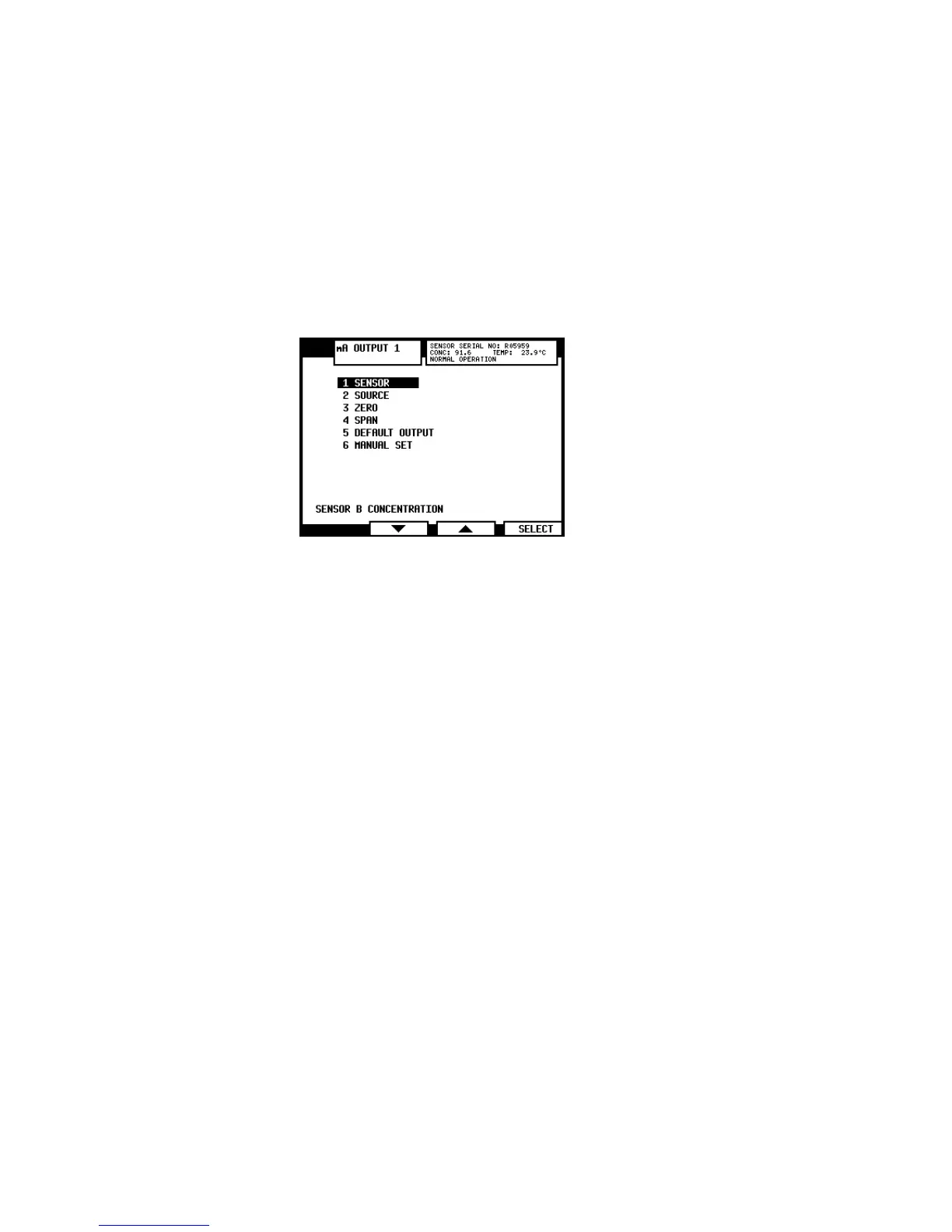

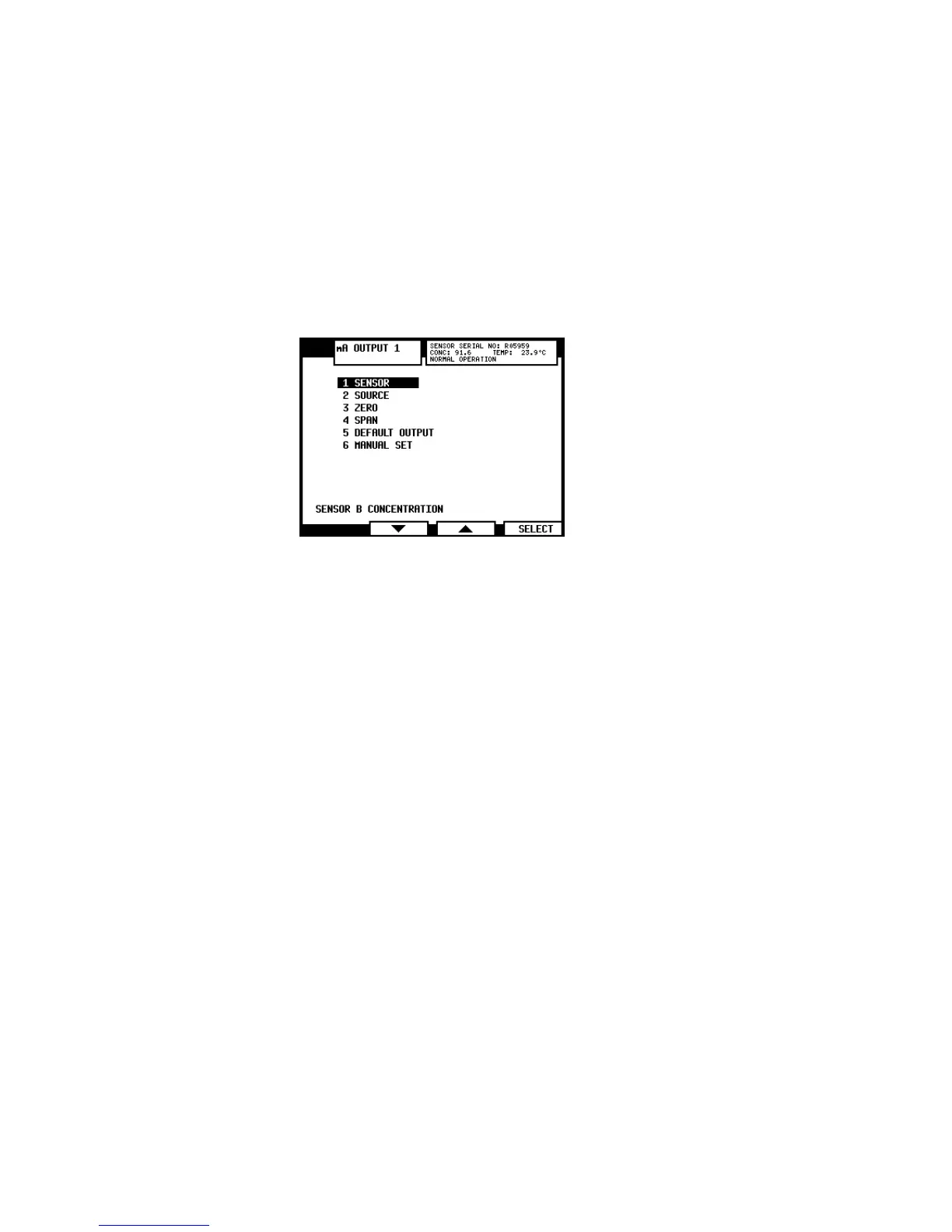

− Select the mA output, 1 or 2, to get to the Output menu (Figure 6.10 below) where

the output can be conigured.

Note: The line at the bottom of the Output menu display indicates the current

coniguration of the selected mA output, e.g. in Figure 6.10 mA Output 1 has been

conigured to send the concentration reading of Sensor B.

Figure 6.10 The Output menu for mA Output 1

− To change the sensor the selected output is assigned to, select 1 SENSOR in the Out-

put menu.

− To change output source for the selected output, select 2 SOURCE.

Note: Selecting 1 NOT DEFINED ’turns off’ the selected output.

− The 3 ZERO value sets the value when the signal is 4 mA. The default zero value is

0.00, the unit depends on the source and display unit set for the sensor in question

(and can thus be for example 0 BRIX or 0 °F).

− The 4 SPAN sets the range, i.e. the value given when the signal is 20 mA.

Example: If your measurement unit is CONC% and you want to measure the range 15–

25 CONC%, irst choose concentration as mA output source. Then set the zero value at

15 and span at 10. This means that the output signal is 4 mA at 15 CONC% and 20 mA

at 15+10=25 CONC%. To change this output to range 10–30 CONC%, change zero to

10 and span to 20 (10+20=30).

− 5 DEFAULT OUTPUT sets a mA default output value that the instrument returns to

in certain malfunction situations. The value can be set to a low or high mA value,

e.g. 3.0 mA or 22 mA. The factory setting for default output is 3.4 mA. For a list of

malfunctions that are affected, see section 8.4.

Note: NAMUR is an international association of users of automation in process in-

dustries. The association recommendation NE 43 promotes a standardization of the

signal level for failure information. The goal of NE 43 is to set a basis for proactively

using transmitter failure signals in process control strategies. Using these failure sig-

nals, instrument faults are separated from process measurements.

Loading...

Loading...