Board switch bizhub C350 Field Service Ver.1.0 Mar. 2004

3-14

III Adjusting/Setting

4.2.1 Adjustment of the sensor output

• Be sure to make this adjustment after replacing the Punch Control Board, the Side Reg-

istration Sensor (Photosensor Board or LED Board) or the Punch Dust Full Sensor

(Punch Dust Full Sensor Board or Punch Dust Full LED Board).

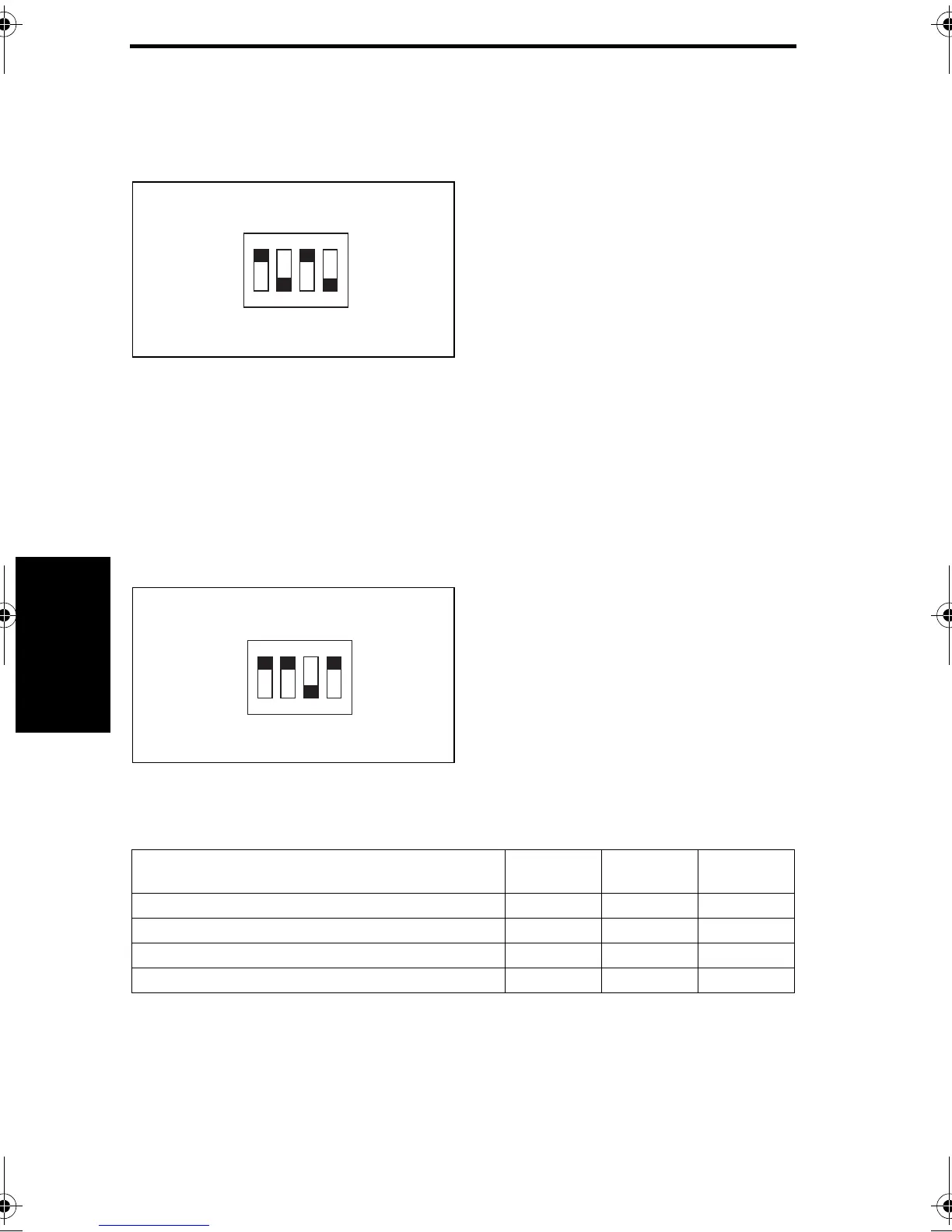

1. Set the bits 1 through 4 of

DIPSW1001 on the Punch Control

Board as shown on the Left figure.

2. Press SW1002 or SW1003 on the

Punch Control Board. The sensor

output will be automatically adjusted.

• When all LED1001, LED1002 and

LED1003 light up, the adjustment has

been completed.

3. Set all bits of DIPSW1001 to OFF.

4.2.2 Registration of the number of punch holes

• In order for the Finisher to recognize the number of punch holes that can be achieved by

the installed Punch Unit, such number of punch holes is registered in the IC on the

Punch Control Board. Make this registration whenever the Punch Control Board has

been replaced.

• However, this registration is not necessary if the EEP-ROM used on an old board has

been reinstalled to a new board.

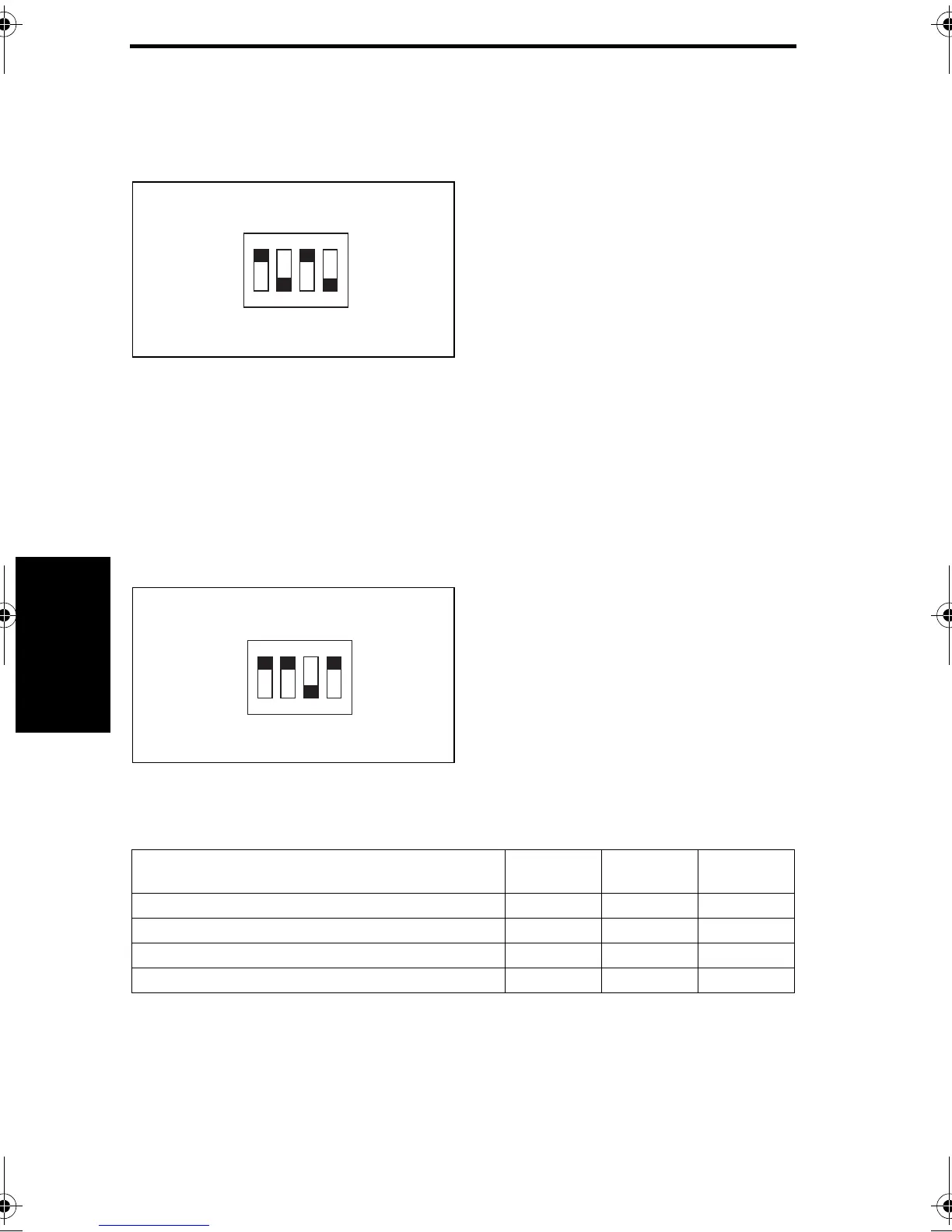

1. Set the bits 1 through 4 of

DIPSW1001 on the Punch Control

Board as shown on the Left figure.

2. Press SW1002 on the Punch Control Board to select the number of punch holes.

• Each time SW1002 is pressed, the following display changes in the descending order

shown below:

3. Press SW1003 on the Punch Control Board twice. The number of punch holes will be

registered in the Punch Control Board.

• The pressing of SW1003 changes the steady lighting of the LED to flickering, and the

pressing of SW1003 again changes the flickering of the LED to steady lighting. This com-

pletes the registration.

4. Set all bits of DIPSW1001 to OFF.

ON

1234

4583fs3515c0

ON

1234

4583fs3516c0

Number of punch holes

LED

1001

LED

1002

LED

1003

2 (Punch Unit J1) ON OFF OFF

2/3 (Punch Unit K1) ON ON OFF

4 (Punch Unit G1) OFF ON OFF

4 (Punch Unit H1) OFF OFF ON

C350_FS_E.book 14 ページ 2004年3月11日 木曜日 午後5時6分

Loading...

Loading...