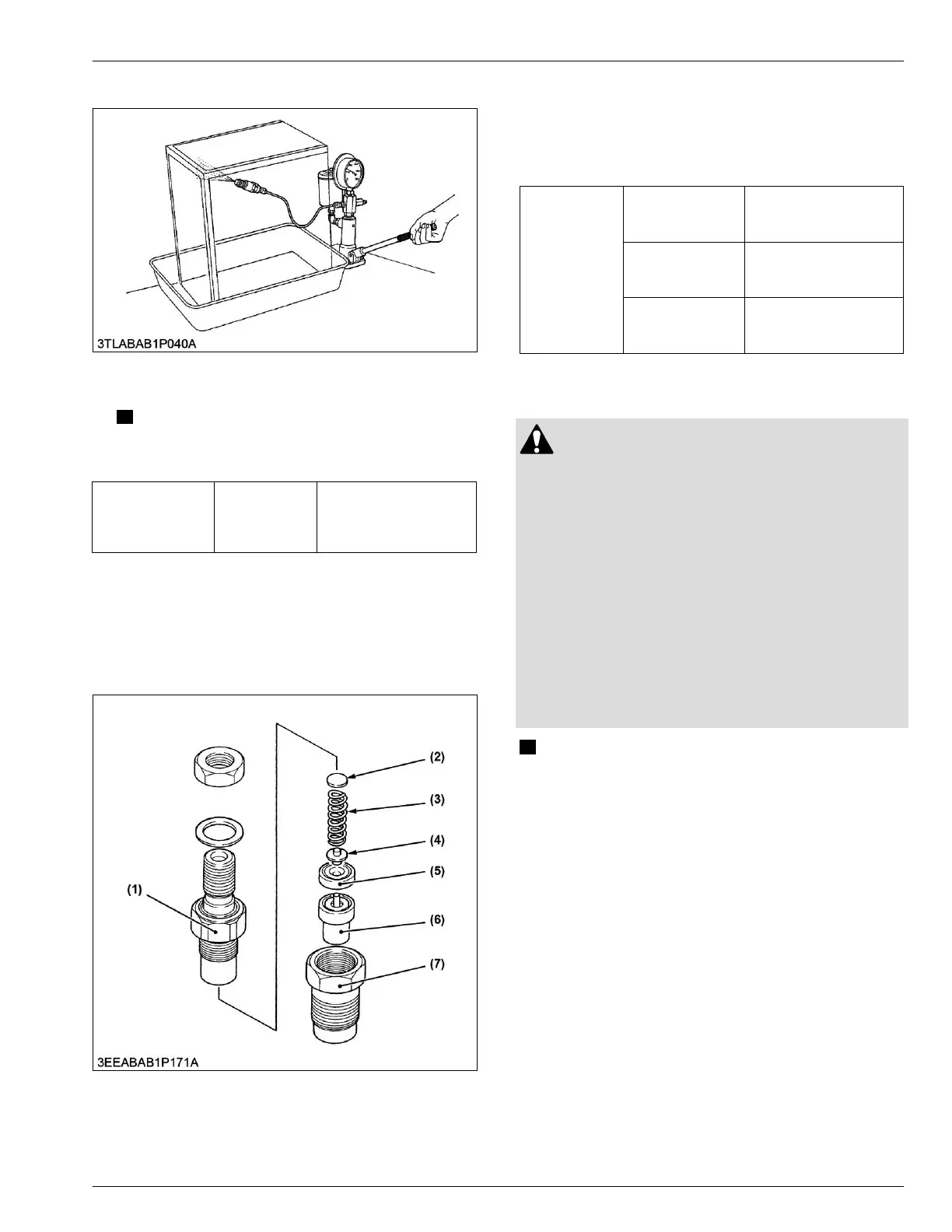

1. Set the injection nozzle to the nozzle tester.

2. Raise the fuel pressure, and keep at specified

pressure for 10 seconds.

NOTE

• If any fuel

leak is found, replace the nozzle

piece.

Valve seat tight-

ness

Service specifi-

cation

No fuel leak at

12.75 MPa

130.0 kgf/cm

2

1849 psi

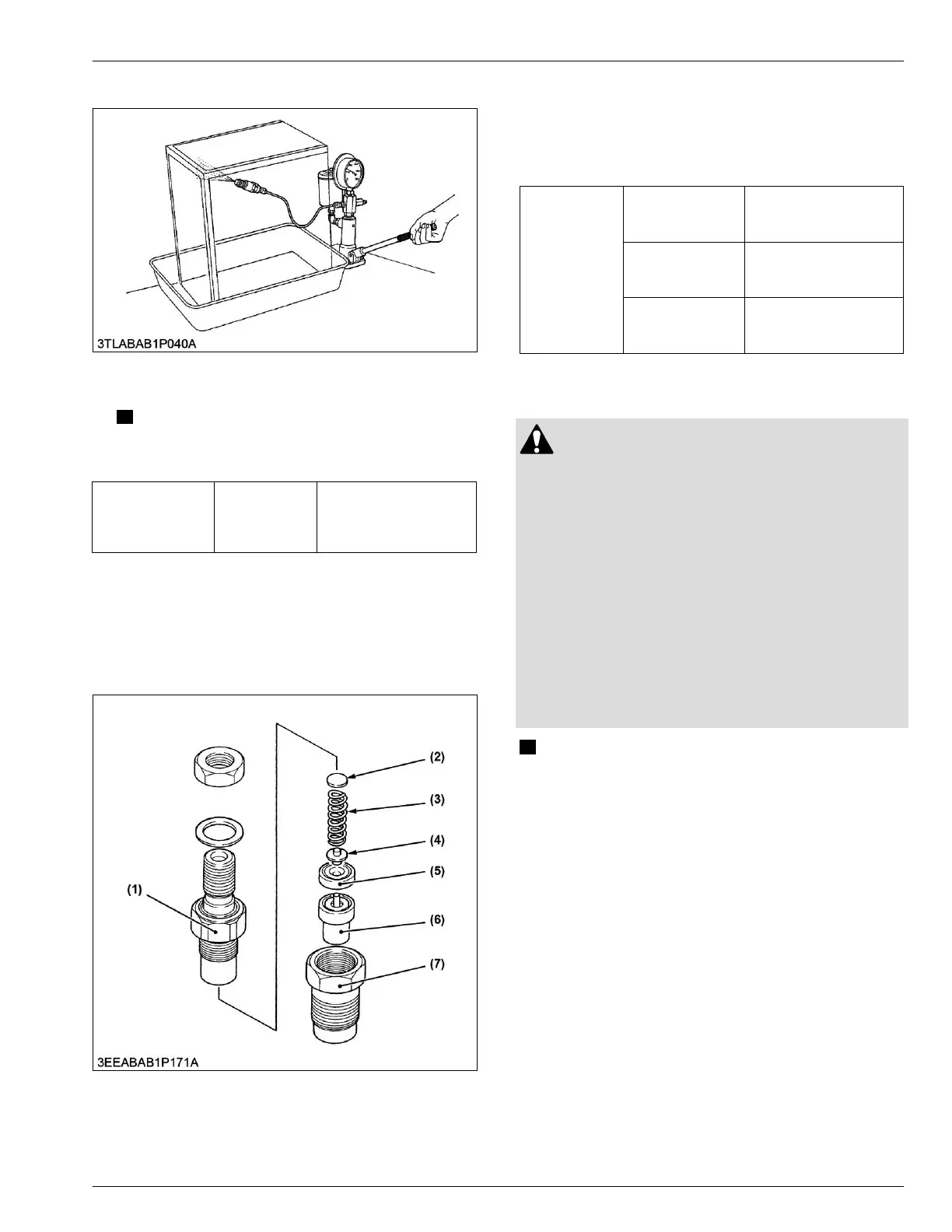

4.15 Adjusting injection nozzle

1. Secure the nozzle retaining nut (7) with a vise.

2.

Remove the nozzle holder (1).

3.

Remove the inside parts.

(1) Nozzle holder

(2) Adjusting washer

(3) Nozzle spring

(4)

Push rod

(5) Distance piece

(6) Nozzle piece

(7) Nozzle retaining nut

(When reassembling)

• Assemble the nozzle in clean fuel oil.

• Install the push rod (4), noting its direction.

•

After assembling the nozzle, be sure to adjust the

fuel injection pressure.

Tightening tor-

que

Nozzle holder

35 to 39 N⋅m

3.5 to 4.0 kgf⋅m

26 to 28 lbf⋅ft

Overflow pipe re-

taining nut

35 to 39 N⋅m

3.5 to 4.0 kgf⋅m

26 to 28 lbf⋅ft

Nozzle holder as-

sembly

49 to 68 N⋅m

5.0 to 7.0 kgf⋅m

37 to 50 lbf⋅ft

4.16 Checking battery voltage

CAUTION

• To prevent

an accidental short circuit, attach

the positive cable to the positive terminal before

the negative cable is attached to the negative

terminal.

• Do not remove the battery cap while the engine

operates.

• Keep electrolyte away from eyes, hands and

clothes.

If you are spattered with it, clean with water

immediately.

• Keep open sparks and flames away from the

battery at all times.

Hydrogen gas mixed with oxygen becomes very

explosive.

IMPORTANT

• Do not disconnect

or remove the battery when

you operate engine.

Tools required

• Circuit tester

1. Stop the engine.

SERVICING

4. Checking and adjusting 4. ENGINE

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...