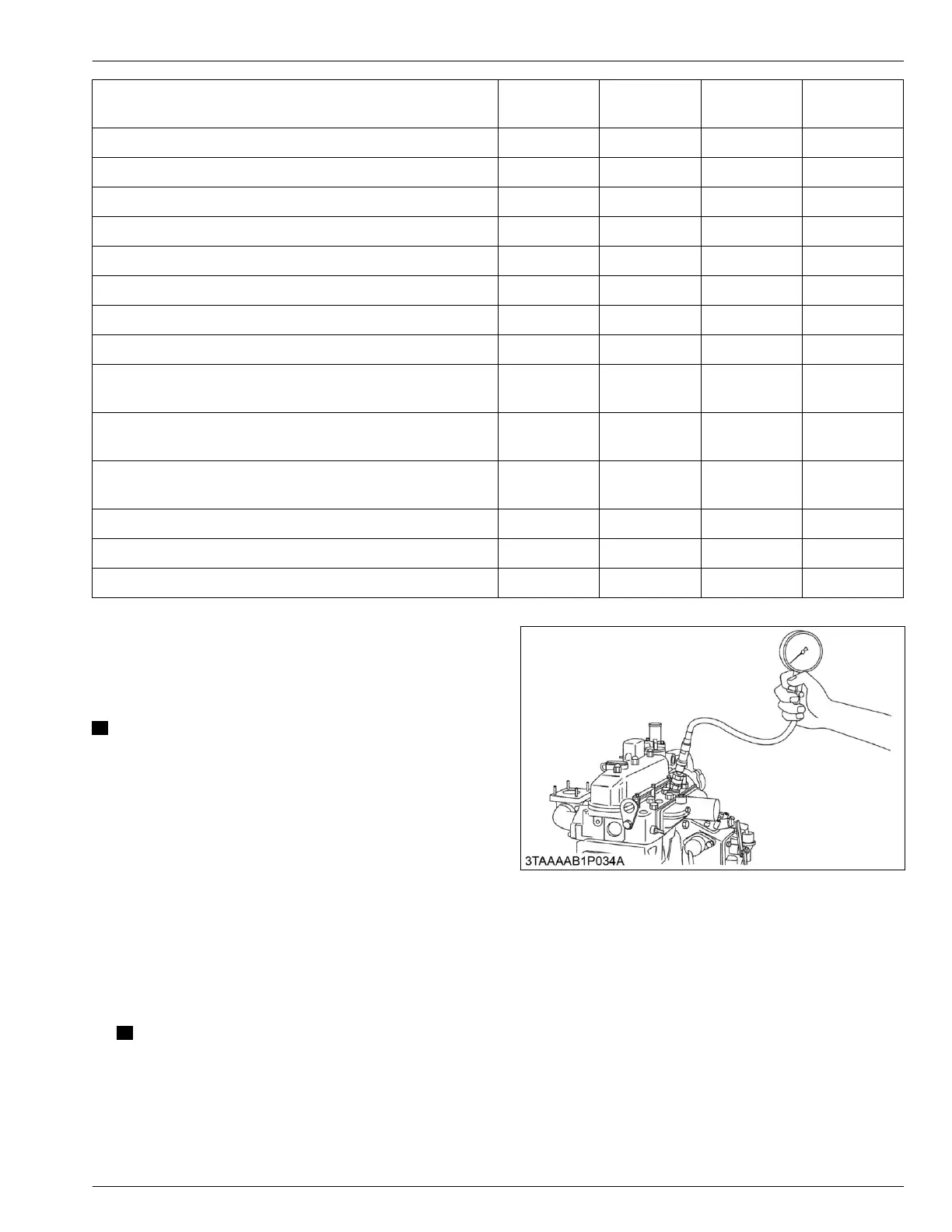

Item

Dimension

× Pitch

N⋅m kgf⋅m lbf⋅ft

*Idle gear shaft screw M6 × 1.0 9.81 to 11.2 1.00 to 1.15 7.24 to 8.31

*Fan drive pulley screw M14 × 1.5 236 to 245 24.0 to 25.0 174 to 180

Bearing case cover mounting screw M6 × 1.0 10.8 to 12.2 1.10 to 1.25 7.96 to 9.04

Glow plug M8 × 1.0 7.9 to 14 0.80 to 1.5 5.8 to 10

Nozzle holder assembly M20 × 1.5 49 to 68 5.0 to 7.0 37 to 50

Nozzle holder - 35 to 39 3.5 to 4.0 26 to 28

Oil pressure switch PT 1/8 15 to 19 1.5 to 2.0 11 to 14

Injection pipe retaining nut M12 × 1.5 25 to 34 2.5 to 3.5 18 to 25

Overflow pipe retaining nut

(Serial No.: below BTZ999)

M12 × 1.5 20 to 24 2.0 to 2.5 15 to 18

Overflow pipe retaining nut

(Serial No.: above BU0001)

M12 × 1.5 35 to 39 3.5 to 4.0 26 to 28

Starter's B terminal nut M8 × 1.25 5.88 to 11.8

0.600 to

1.20

4.34 to 8.70

Alternator's pulley nut - 58.4 to 78.9 5.95 to 8.05 43.1 to 58.2

Drain plug with copper gasket M12 × 1.25 33 to 37 3.3 to 3.8 24 to 27

Drain plug with rubber coated gasket M22 × 1.5 45 to 53 4.5 to 5.5 33 to 39

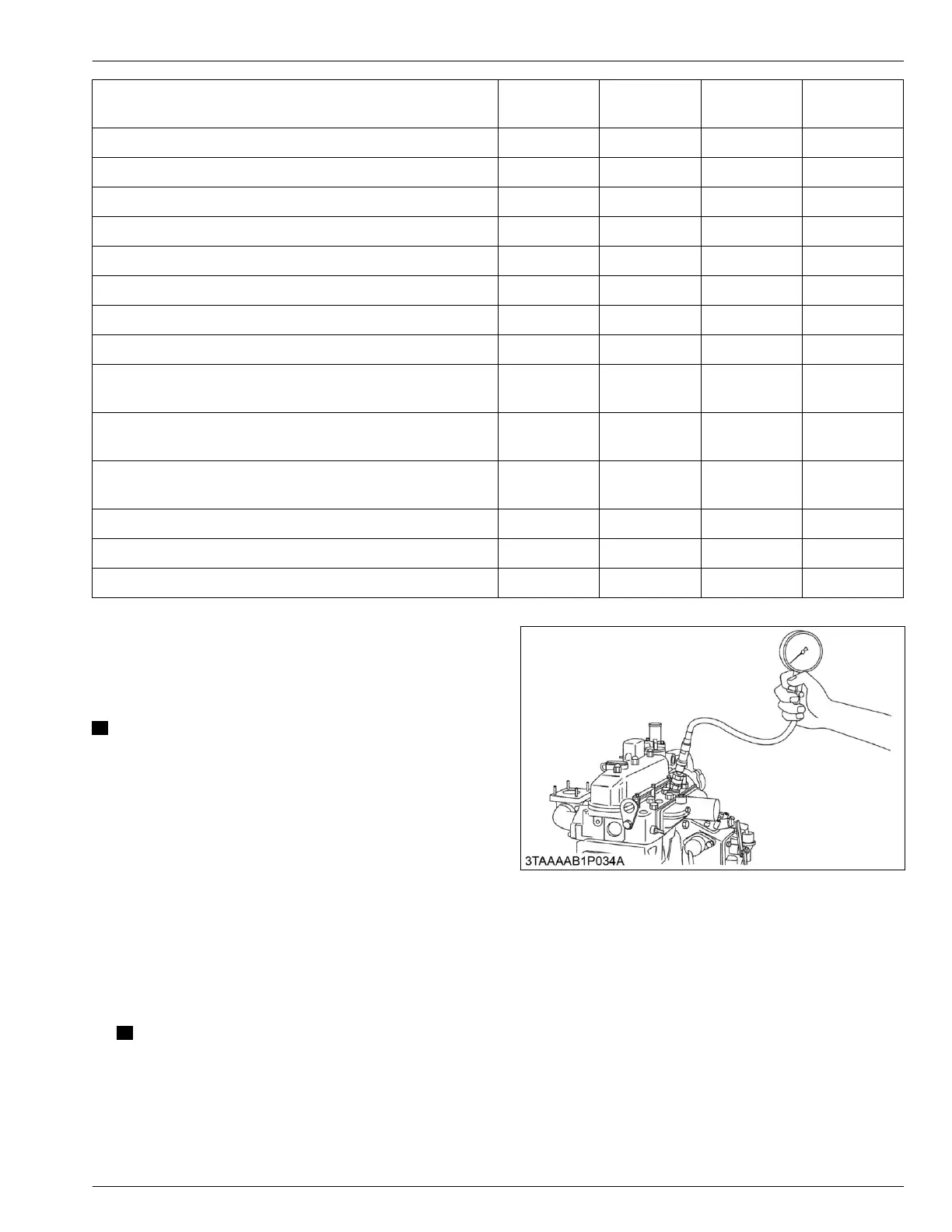

4. Checking and adjusting

4.1 Checking compression pressure

of cylinder

NOTE

• Check the compression

pressure with the

specified valve clearance.

• Always use a fully charged battery for you do

this test.

• Variances in cylinder compression values must

be less than 10 %.

Tools required

• Compression tester

• Injector adapter

1. Warm-up the engine.

2. Stop the engine.

3. Remove the air cleaner and muffler.

4. Remove the all injection nozzles.

NOTE

• In

case

you

use compression tester adapter

for glow plug holes, remove the glow lead

and glow plugs.

5. Set a compression tester (Code No. 07909-30208)

with the adapter (Adapter H, code No.

07909-31231) to the nozzle hole.

6. After

making sure that the stop lever is set at the

stop

position

(non-injection), operate the engine

with the starter and measure the compression

pressure.

SERVICING

4. Checking and adjusting 4. ENGINE

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...