Installing idle gear bushing

1. Clean

a

new

idle gear bushing and idle gear bore,

and apply engine oil to them.

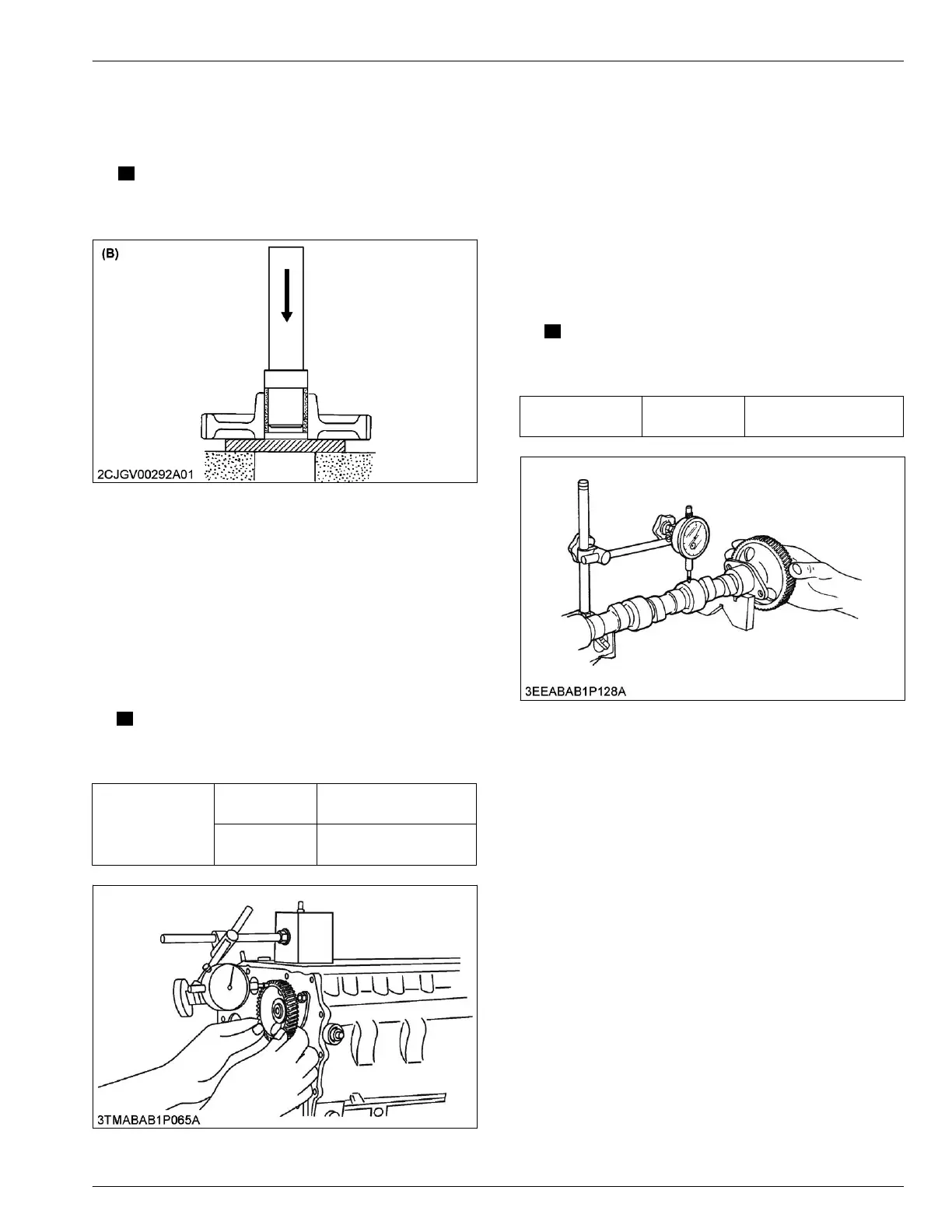

2. Press fit the new bushing with the replacing tool.

NOTE

• Make sure that

the bushing end aligns the

end of the idle gear.

(B) Installing direction

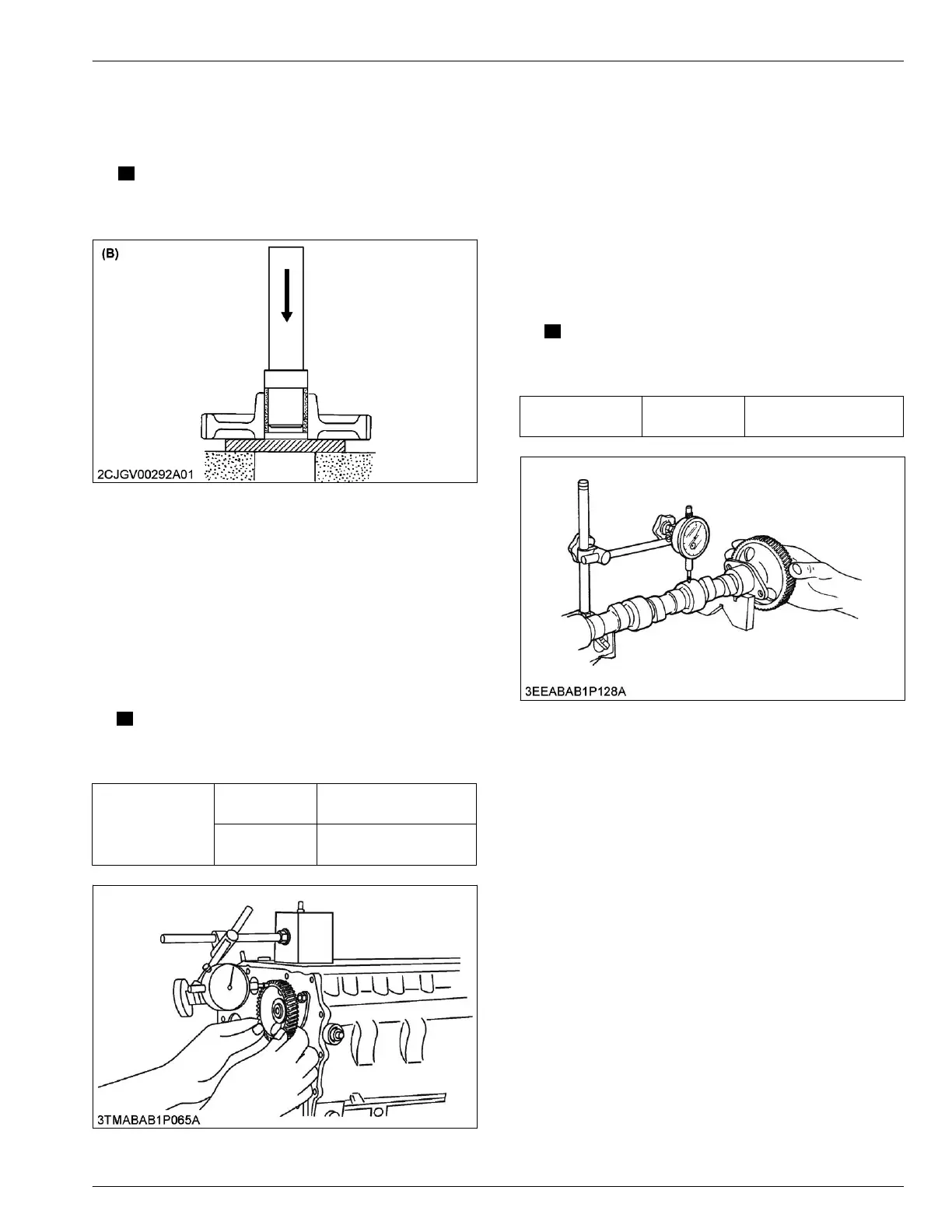

6.20 Checking side clearance of

camshaft

Tools required

• Dial gauge

1. Set a dial gauge with its point on the camshaft.

2.

Move the cam gear to the front and rear to measure

the side clearance.

NOTE

• If the measurement is more than the service

limit, replace the camshaft stopper.

Side clearance of

camshaft

Service specifi-

cation

0.070 to 0.22 mm

0.0028 to 0.0086 in.

Service limit

0.30 mm

0.012 in.

6.21 Checking camshaft alignment

Tools required

• V blocks

• Surface plate

•

Dial gauge

1. Hold the two end journals of camshaft with V blocks

on the surface plate.

2. Set a dial gauge with its point on the middle journal.

3. Turn the camshaft slowly and measure the variation

on the indicator (Camshaft alignment is half of the

measured value).

NOTE

• If

the

measurement

is more than the service

limit, replace the camshaft.

Camshaft align-

ment

Service limit

0.01 mm

0.0004 in.

6.22 Checking cam height

Tools required

• Outside micrometer

SERVICING

6. Servicing 4. ENGINE

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...