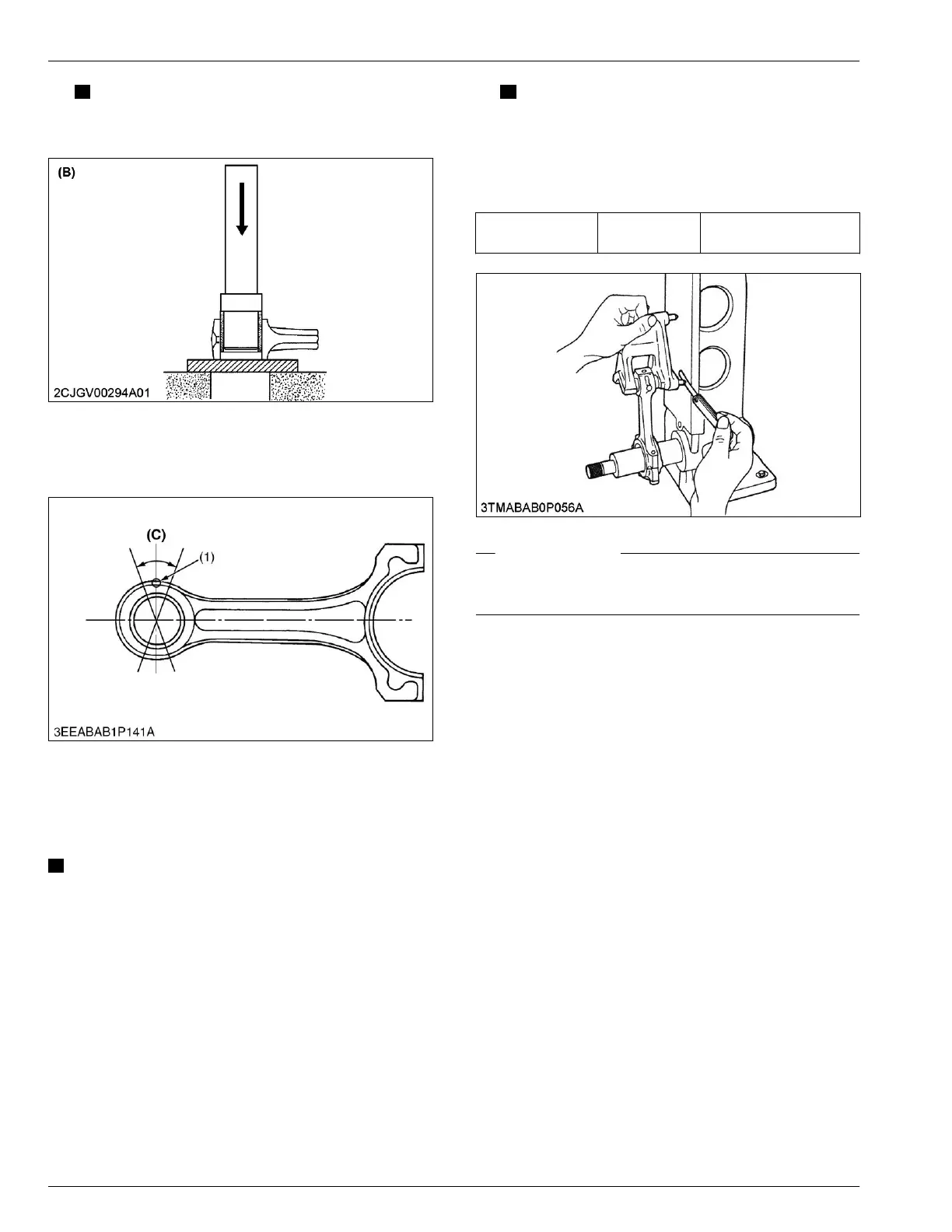

NOTE

Apply engine oil

to the new small end bushing

and bore.

(B) Installing direction

3. Press-fit

it with

a press so that the seam (1) of

bushing positions as shown in the figure, until it

comes in contact with the connecting rod.

(1) Seam (C) 0.26 rad (15°)

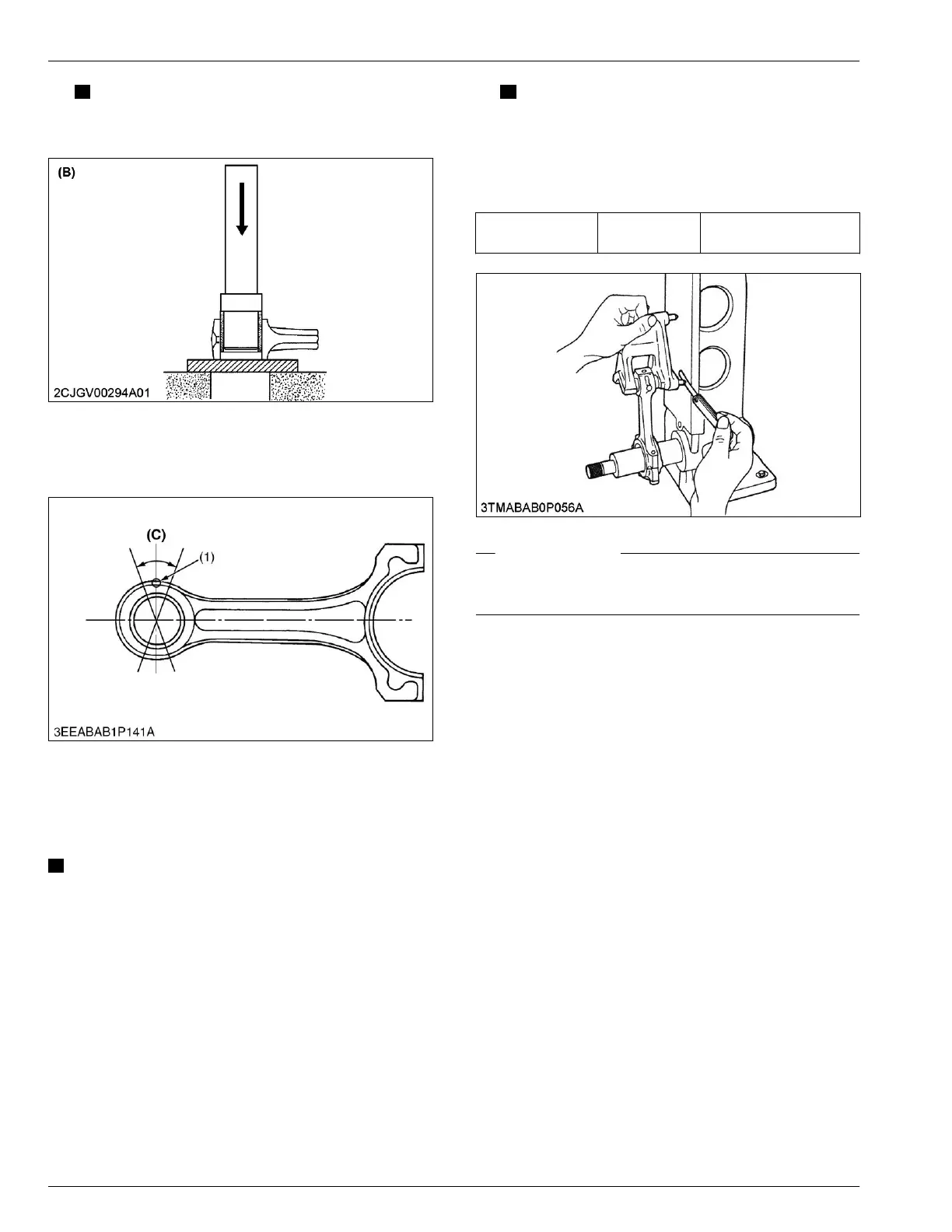

6.27 Checking connecting rod

alignment

NOTE

• Make sure that

the oil clearance of the small

end bushing is less than the service limit.

Tools required

• Connecting rod alignment tool

• Feeler gauge

1. Remove the piston pin from the piston.

2. Install the piston pin into the connecting rod.

3. Install

the connecting rod on the alignment tool for

the connecting rod.

4. Put a gauge on the piston pin, and move it against

the face plate.

NOTE

• If the gauge

does not touch fully against the

face plate, measure the space between the

gauge pin and face plate.

• If the measurement is more than the service

limit, replace the connecting rod.

Connecting rod

alignment

Service limit

0.05 mm

0.002 in.

RELATED PAGE

6.25 Checking oil clearance between piston pin and

small end bushing on page 4-61

6.28 Checking piston ring gap

Tools required

• Feeler gauge

1. Put

the piston ring into the lower part of the liner

(the least worn out part) with the piston.

4. ENGINE

SERVICING

6. Servicing

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...