1. Clean the crankpin and crankpin bearing.

2. Put

a

strip

of plastigauge on the center of the

crankpin.

NOTE

• Do not put

the plastigauge into the crankpin

oil hole.

3. Install the connecting rod cap.

4. Tighten the connecting rod screws to the specified

torque.

NOTE

• When you tighten the connecting rod

screws, do not move the crankshaft.

Tightening tor-

que

Connecting rod

screw

42 to 46 N⋅m

4.3 to 4.6 kgf⋅m

31 to 33 lbf⋅ft

5. Remove the connecting rod cap again.

6. Measure

the

width

that it becomes flat with the

scale to get the oil clearance.

NOTE

• If the clearance

more than the service limit,

replace the crankpin bearing.

• If the same dimension bearing is not

applicable because of the crankpin wear,

replace it with an undersize one.

Crankpin O.D.

Service specifi-

cation

39.959 to 39.975 mm

1.5732 to 1.5738 in.

Crankpin bearing

I.D.

Service specifi-

cation

40.040 to 40.050 mm

1.5764 to 1.5767 in.

Oil clearance be-

tween crankpin

and crankpin bear-

ing

Service specifi-

cation

0.029 to 0.091 mm

0.0011 to 0.0036 in.

Service limit

0.20 mm

0.0079 in.

(Reference)

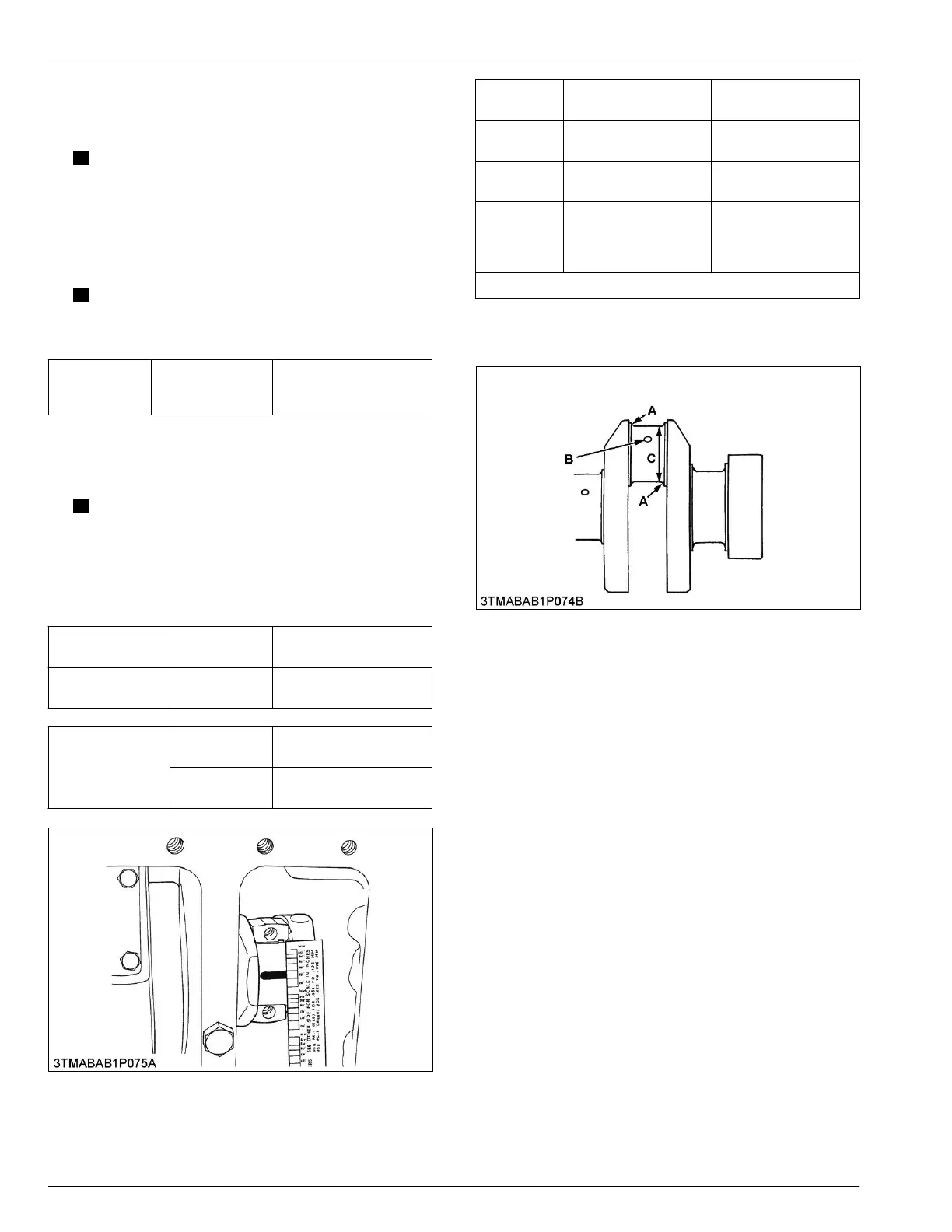

• Undersize dimensions of crankpin

Undersize

0.20 mm

0.0079 in.

0.40 mm

0.016 in.

Dimension A

2.8 to 3.2 mm radius

0.11 to 0.12 in. radius

2.8 to 3.2 mm radius

0.11 to 0.12 in. radius

Dimension

B

*

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

1.0 to 1.5 mm relief

0.040 to 0.059 in. relief

Dimension

C

39.759 to 39.775 mm

dia.

1.5654 to 1.5659 in.

dia.

39.559 to 39.575 mm

dia.

1.5575 to 1.5580 in.

dia.

The crankpin must be fine-finished to higher than Rmax = 0.8 S

* Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.040 to 0.059 in.) relief.

A: Dimension A

B: Dimension B

C: Dimension C

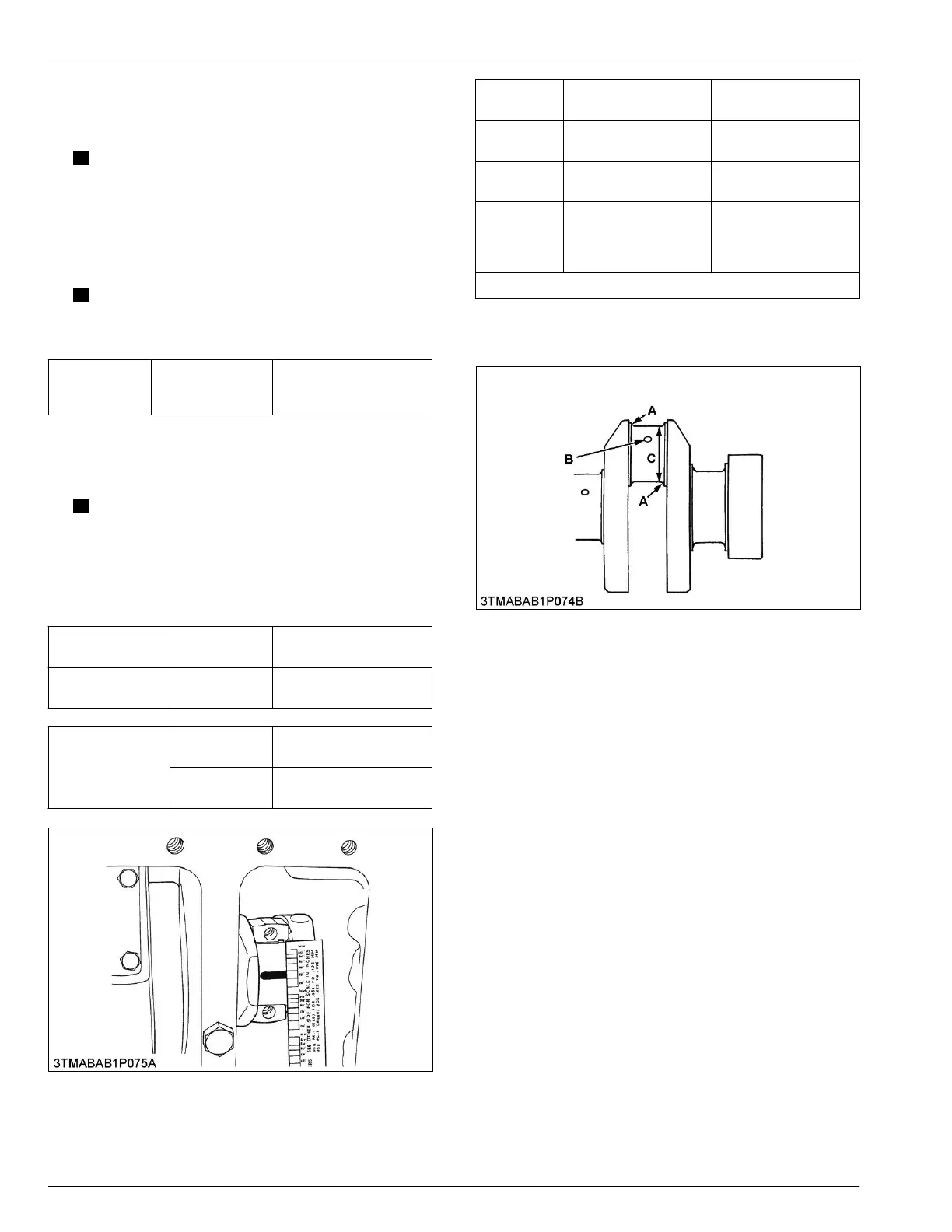

6.33 Checking oil clearance between

crankshaft journal and crankshaft

bearing 1

T

ools required

• Inside micrometer

• Outside micrometer

4. ENGINE

SER

VICING

6. Servicing

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...