2. If

the cylinder wear is more than the service limit,

bore and hone it to the specified dimension.

NOTE

• If the maximum

I.D. or the difference for the

oversize cylinder is more than the service

limit, replace the crankcase with a new one.

• Oversize cylinder bore I.D.

Oversize cyl-

inder I.D.

Service

specifica-

tion

D1005-

E4B/

E4BG

76.500 to

78.619 mm

3.0119 to 3.0125 in.

D1105-

E4B/

E4BG

D1305-

E4B/

E4BG

V1505-

E4B/

E4BG

78.500 to

78.519 mm

3.0906 to 3.0912 in.

Service lim-

it

D1005-

E4B/

E4BG

76.65 mm

3.018 in.

D1105-

E4B/

E4BG

D1305-

E4B/

E4BG

V1505-

E4B/

E4BG

78.65 mm

3.096 in.

Finishing

Hone to 1.2 to 2.0 μmR max. (48 to 78 μin.R

max.)

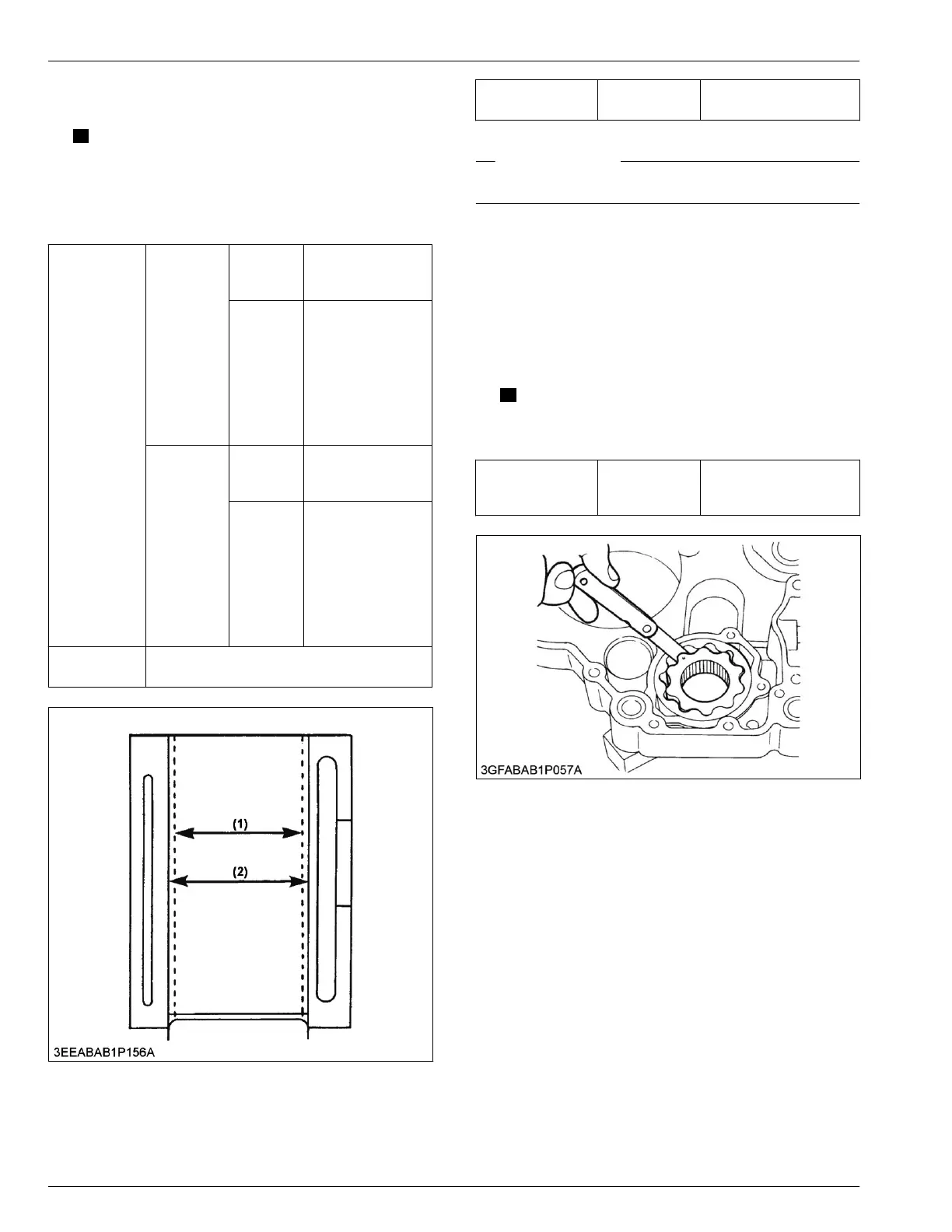

(1) Cylinder bore I.D. (Before

correction)

(2) Cylinder bore I.D. (Oversize)

3. Replace

the

piston

and piston rings with oversize

ones.

Oversize piston

and piston rings

Service specifi-

cation

0.50 mm

0.020 in.

RELATED PAGE

6.37 Checking cylinder wear on page 4-70

6.39 Checking clearance between

inner rotor and outer rotor

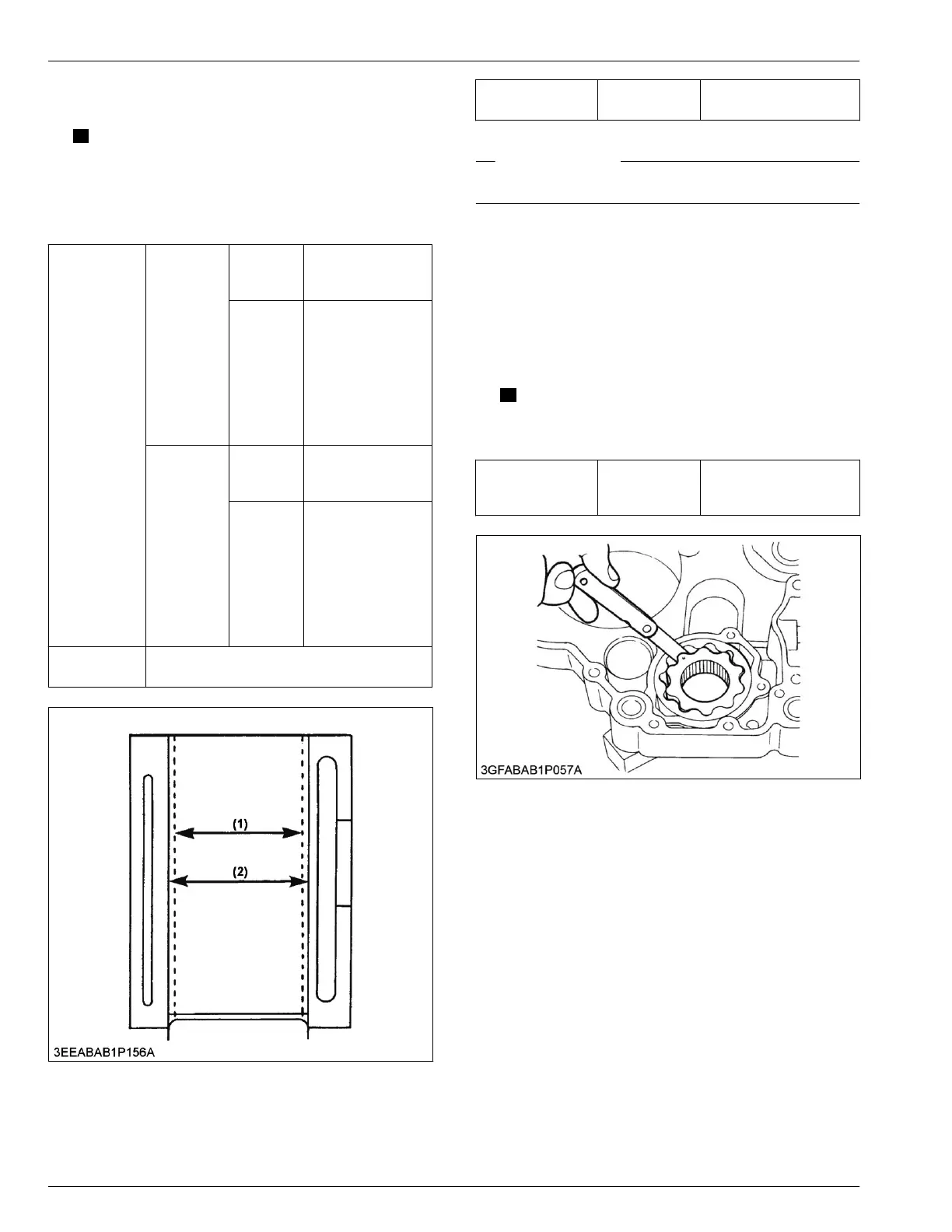

Tools required

• Feeler gauge

1. Measure

the clearance between the lobes of the

inner rotor and the outer rotor with a feeler gauge.

NOTE

• If the clearance

more than the service limit,

replace the oil pump rotor assembly.

Clearance be-

tween inner rotor

and outer rotor

Service specifi-

cation

0.060 to 0.18 mm

0.0024 to 0.0071 in.

6.40 Checking clearance between

outer rotor and pump body

Tools required

• Feeler gauge

4. ENGINE

SERVICING

6. Servicing

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...