2. Move

the crankshaft to the front and rear to

measure the side clearance.

NOTE

• If the measurement

is more than the service

limit, replace the thrust bearings.

• If the same dimension bearing is not

applicable because of the crankshaft journal

wear, replace it with an oversize one. Refer

to the table and figure.

Side clearance of

crankshaft

Service specifi-

cation

0.15 to 0.31 mm

0.0059 to 0.012 in.

Service limit

0.50 mm

0.020 in.

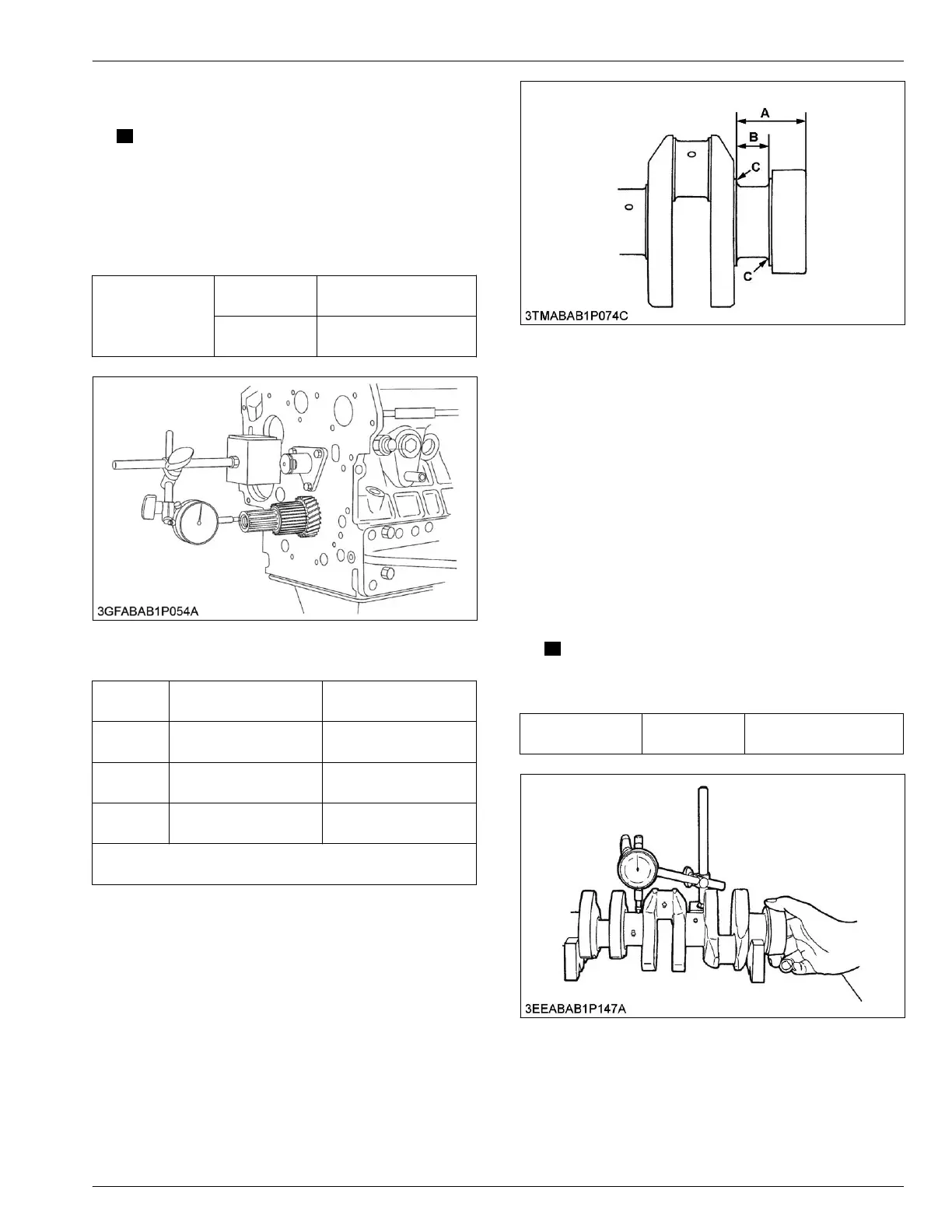

(Reference)

•

Oversize dimensions of crankshaft journal

Oversize

0.20 mm

0.0079 in.

0.4 mm

0.016 in.

Dimension

A

51.50 to 51.70 mm

2.028 to 2.035 in.

51.60 to 51.80 mm

2.032 to 2.039 in.

Dimension

B

28.20 to 28.25 mm

1.11

1 to 1.1

12 in.

28.40 to 28.45 mm

1.119 to 1.120 in.

Dimension

C

2.3 to 2.7 mm radius

0.091 to 0.10 in. radius

2.3 to 2.7 mm radius

0.091 to 0.10 in. radius

The crankshaft journal must be fine-finished to higher than Rmax

= 0.8 S.

A: Dimension A

B: Dimension B

C: Dimension C

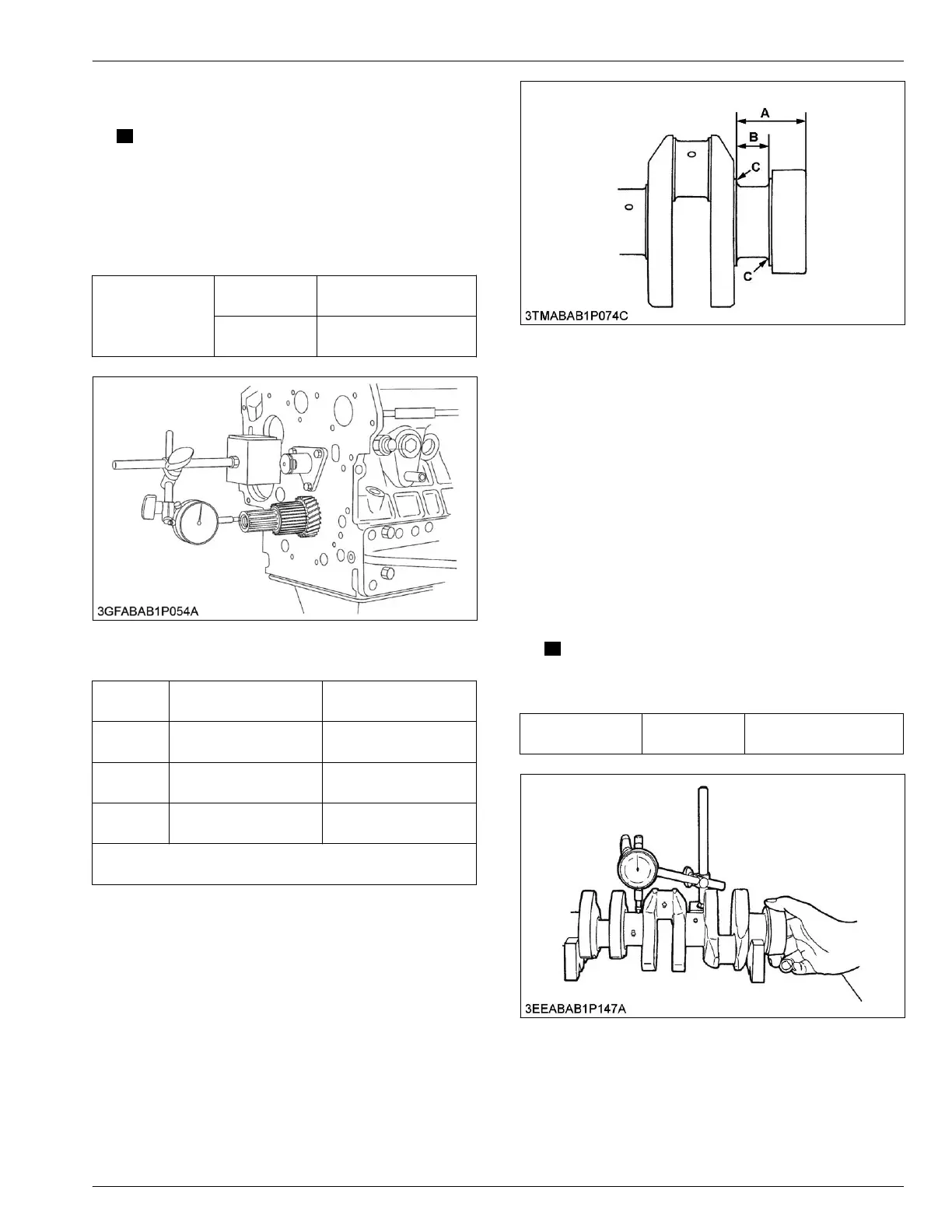

6.31 Checking crankshaft alignment

T

ools required

• V blocks

• Surface plate

•

Dial gauge

1. Hold the two end journals of crankshaft with V

blocks on the surface plate.

2. Set a dial gauge with its point on the middle journal.

3. Turn the crankshaft slowly and read the variation on

the indicator. Half of the measured value is the

alignment value.

NOTE

• If the measurement

is more than the service

limit, replace the crankshaft.

Crankshaft align-

ment

Service limit

0.02 mm

0.0008 in.

6.32 Checking oil clearance between

crankpin and crankpin bearing

Tools required

• Plastigauge

SERVICING

6. Servicing 4. ENGINE

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...