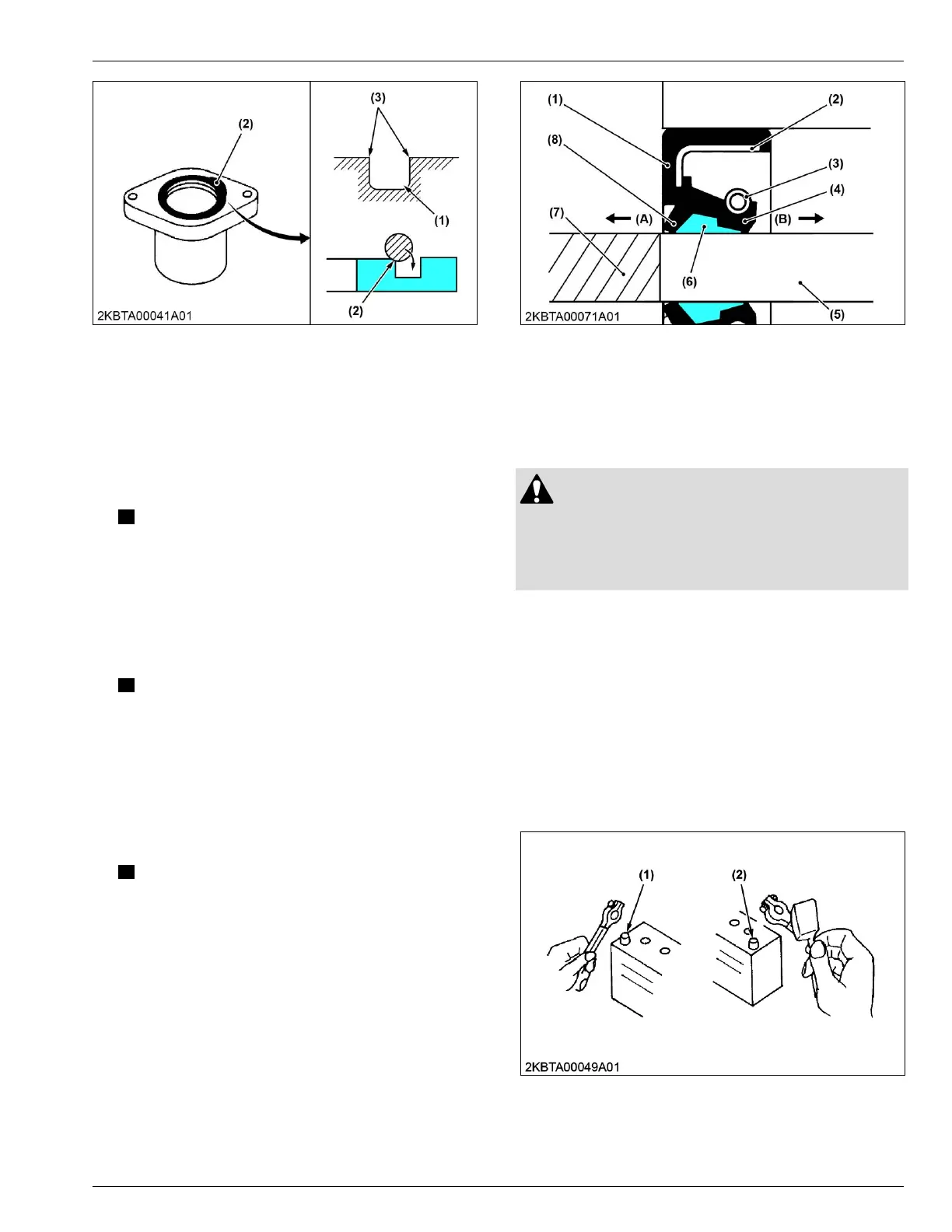

(1) O-ring groove

(2) O-ring

(3) Burr

6.

Replacing oil seals

1. If

there are burrs, scratches, or rust on the inner

surface

of

the housing hole, the chamfered part, or

the surface of the shaft through which the oil seal

passes, remove it with sandpaper.

NOTE

• If there is

a risk of splines or key grooves of

the shaft damaging the lip part of the seal,

wrap masking tape around those parts to

protect the seal.

2. Clean the inner surface of the housing hole and the

surface of the shaft.

3. Lubricate the seal lip and dust lip.

NOTE

• If the seal

has a dust lip, grease the gap

between the lips to prevent dry wear that

occurs when the machine starts.

• Use the specified grease or oil to lubricate

the lip.

4. With the seal lip facing the airtight side (B) of the

object, use a press to press-fit the oil seal until it is

fixed to the boss.

NOTE

• In cases when

installing an oil seal without a

press, place a wooden board on the seal

and gently tap the board with a hammer;

install the oil seal straightly and evenly.

(1) Packing

(2) Metal ring

(3) Spring

(4)

Seal lip

(5) Shaft

(6) Grease

(7) Masking tape

(8) Dust lip

(A) Air side

(B) Airtight side

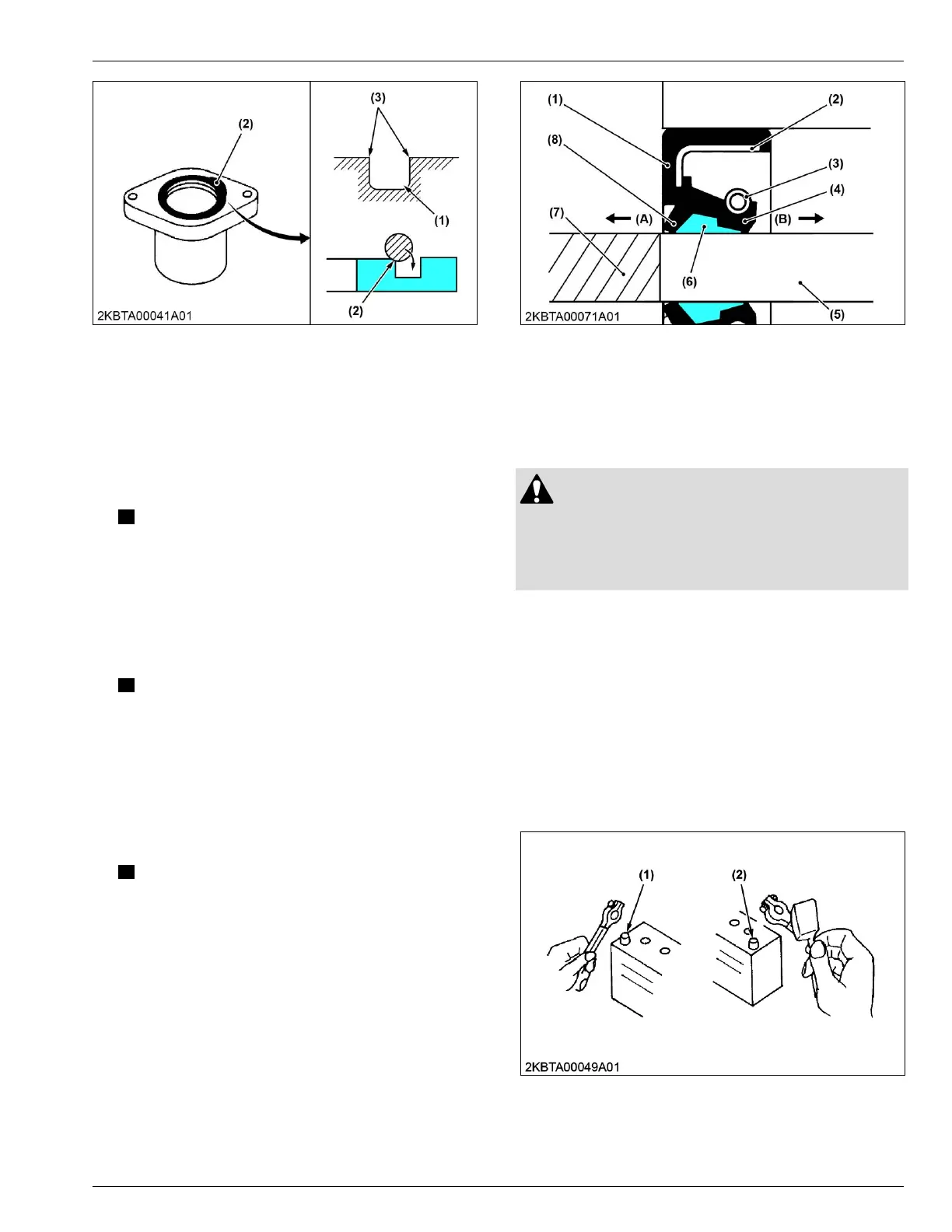

7. Handling the battery

CAUTION

• When removing battery

cables, disconnect

negative (-) terminal first.

• When installing battery cables, connect positive

(+) terminal first.

• Do not install any battery with a capacity (Ah) other

than is specified.

• Securely attach the terminal covers on the cables

when connecting the cables to the battery terminal

posts. There is a danger of short-circuiting if the tip

of the cables attached to the battery terminal post is

exposed.

• Do not allow dirt and dust to collect on the battery.

• Connect the battery terminals after removing dust,

old grease, blue rust and others.

• Apply conductive grease thinly to the battery

terminal posts to prevent corrosion.

(1) Battery negative (-) terminal (2) Battery positive (+) terminal

GENERAL WORKING PRECAUTIONS

6. Replacing oil seals 2. GENERAL

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...