6.8 Adjusting valve angle

NOTE

• Before you adjust

the valve, check the valve

stem and measure the I.D. of the valve guide

section.

Repair them if necessary.

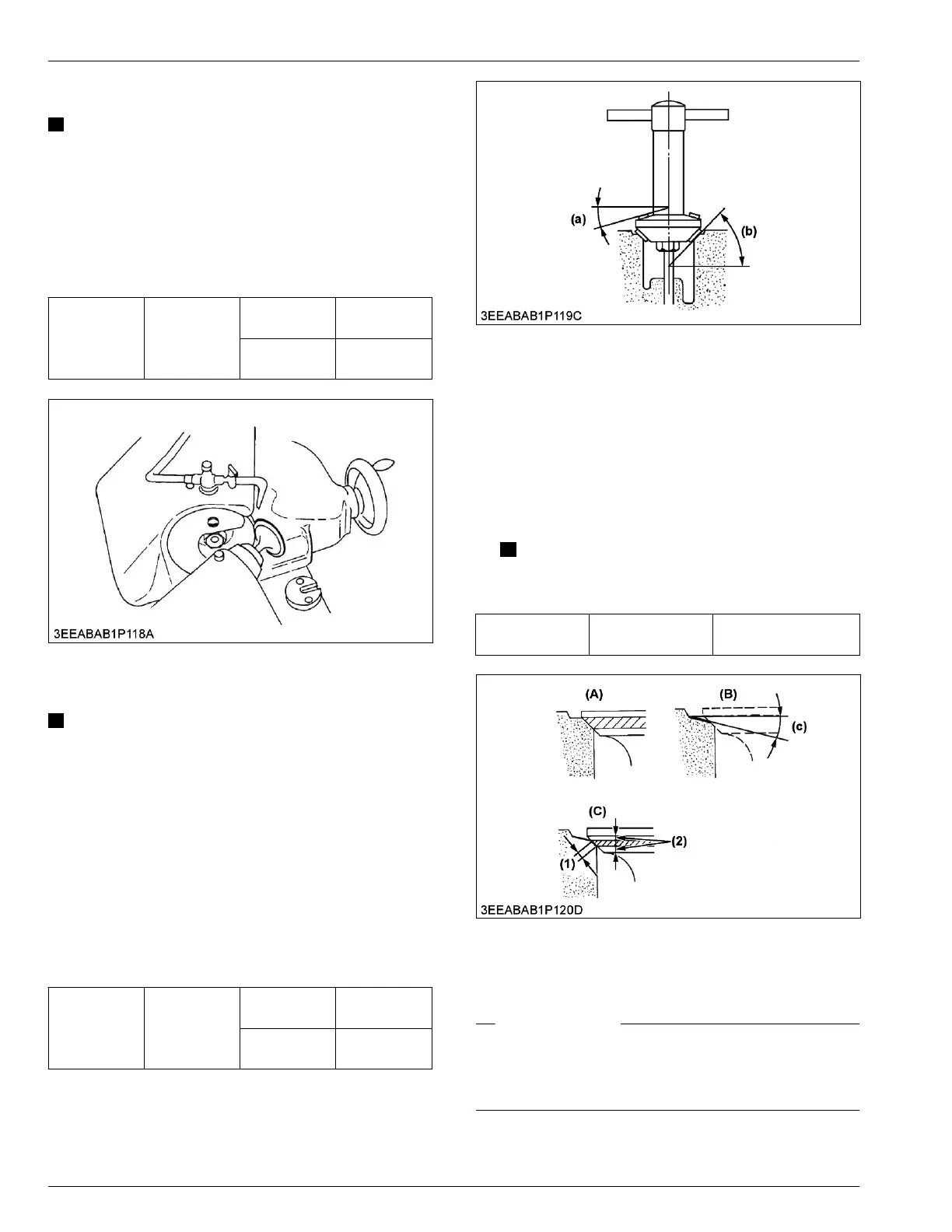

Tools required

• Valve refacer

1. Adjust the valve with a valve refacer.

Valve face an-

gle

Service speci-

fication

Intake valve

1.0 rad

60°

Exhaust valve

0.79 rad

45°

6.9 Adjusting valve seat

NOTE

• Before you adjust

the valve seat, check the

valve stem and measure the I.D. of the valve

guide section.

Repair them if necessary.

• After you adjust the valve seat, be sure to check

the valve recessing.

Tools required

• Valve seat cutter

• Valve lapping tool.

• Prussian Blue

1. Slightly adjust the seat surface with a 1.0 rad (60°)

or 0.79 rad (45°) valve seat cutter.

Valve seat an-

gle

Service speci-

fication

Intake valve

1.0 rad

60°

Exhaust valve

0.79 rad

45°

(a) 0.26 rad (15°) or 0.52 rad

(30°)

(b) 0.79 rad (45°) or 1.0 rad

(60°)

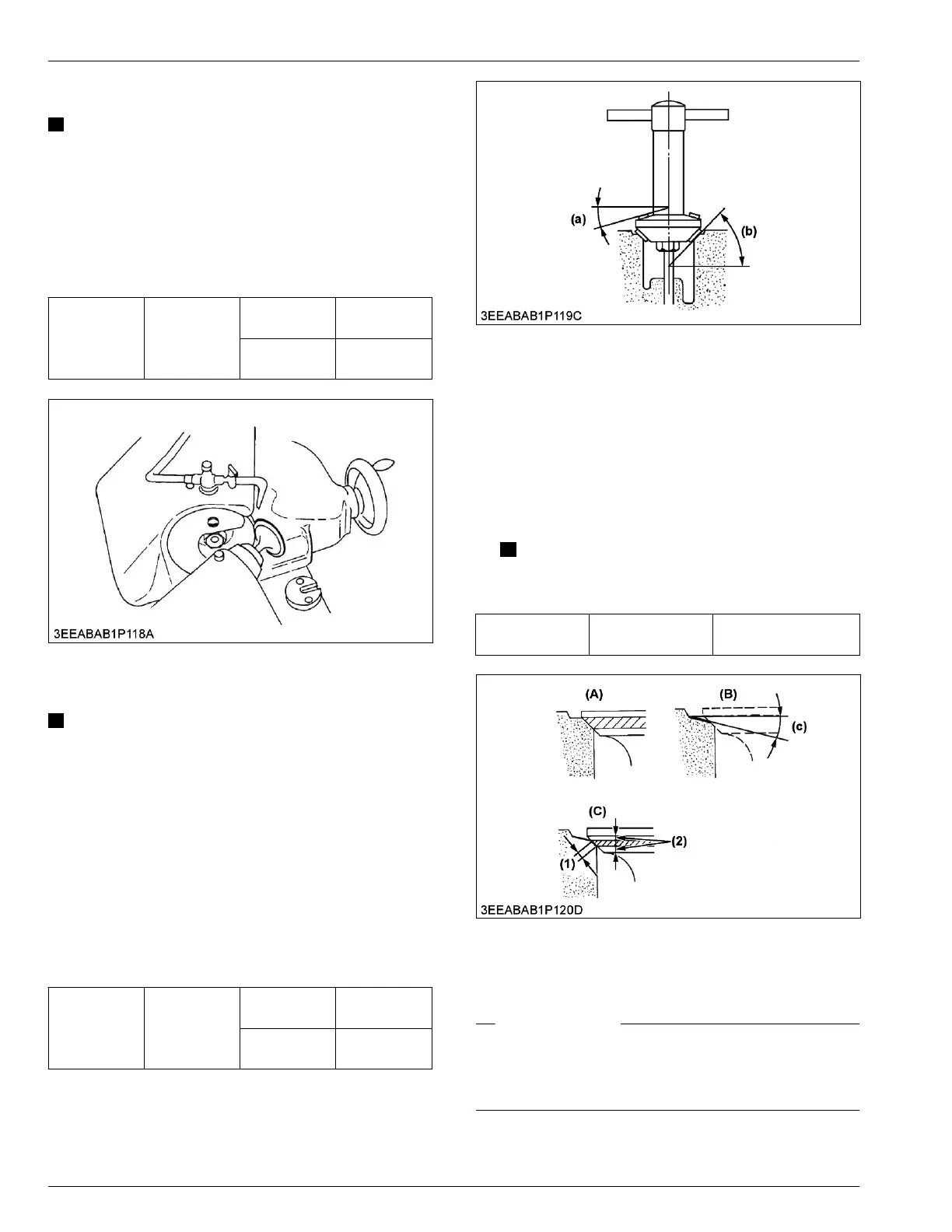

2. Adjust

the seat

width with a 0.52 rad (30°) or

0.26 rad (15°) valve seat cutter.

3. After you adjust the seat, check that the valve

seating is flat.

4. Apply a thin layer of compound between the valve

face and valve seat, and lap them with a valve

lapping tool.

5. Check the valve seating with Prussian Blue.

NOTE

• The valve seating

surface must show good

contact on all sides.

Valve seat width

(1)

Service specifica-

tion

2.12 mm

0.0835 in.

(1) Valve seat width

(2) Identical dimensions

(A) Check the contact

(B)

Correct seat width

(C) Check the contact

(c) 0.52 rad (30°) or 0.26 rad

(15°)

RELATED PAGE

6.4 Checking valve recessing on page 4-51

6.6 Checking clearance between valve stem and

valve guide on page 4-52

4. ENGINE

SERVICING

6. Servicing

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...