4. Check points of every 100

hours

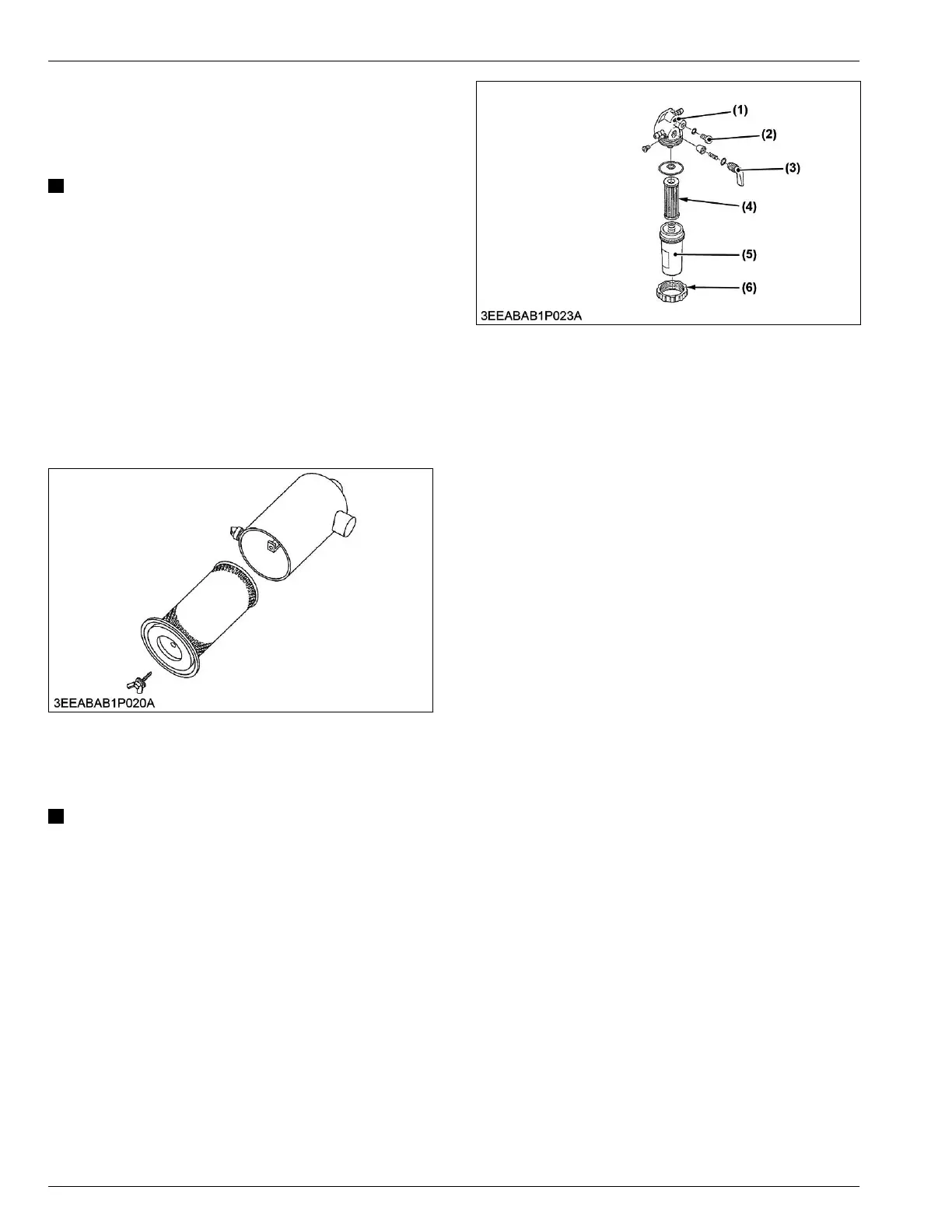

4.1 Cleaning air cleaner element

NOTE

• The air cleaner

uses a dry element. Never apply

oil to it.

• Do not operate the engine with filter element

removed.

• Change the element once a year or every 6th

cleaning.

1. Remove the air cleaner element.

2. Use clean dry

compressed air on the inside of the

element.

Pressure of compressed air must be under 205 kPa

(2.1 kgf/cm

2

, 30 psi).

Keep reasonable distance between the nozzle and

the filter.

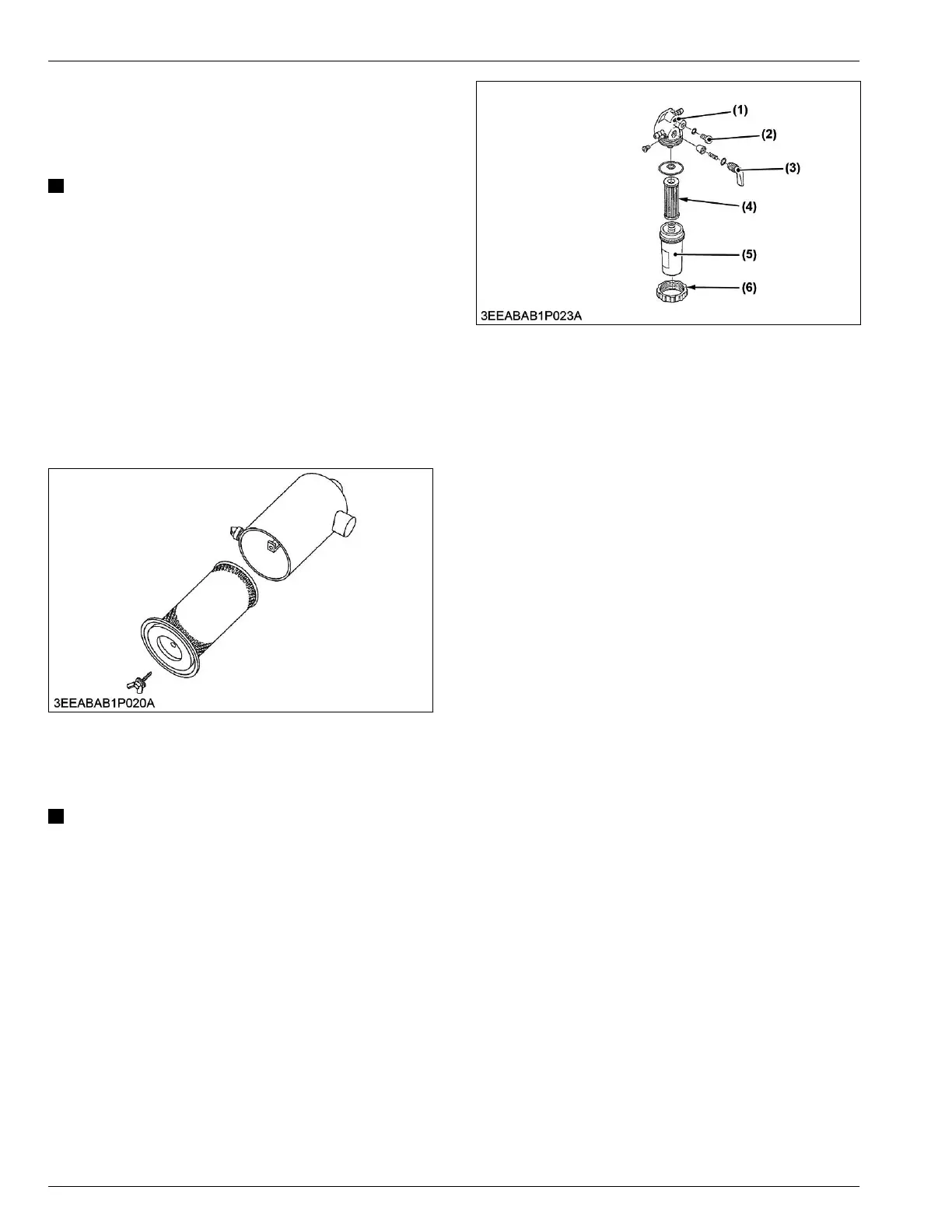

4.2 Cleaning fuel filter

Element type only

IMPORTANT

• If dust and

dirt enter the fuel, the fuel injection

pump and injection nozzle may wear quickly. To

prevent this, be sure to clean the fuel filter cup

(5) periodically.

1. Close the fuel valve (3).

2. Remove the retaining ring (6) and remove the filter

cup (5), and rinse the inside with kerosene.

3. Take out the element (4) and dip it in the kerosene

to rinse.

(1) Fuel valve body

(2) Air vent plug

(3) Fuel valve

(4)

Filter element

(5) Filter cup

(6) Retaining ring

4. After

cleaning, reassemble the fuel filter, keeping

out dust and dirt.

5.

Bleed the fuel system.

4.3 Checking fan belt tension

T

ools required

• Sonic belt tension meter

3. MAINTENANCE

CHECK AND MAINTENANCE

4. Check points of every 100 hours

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...