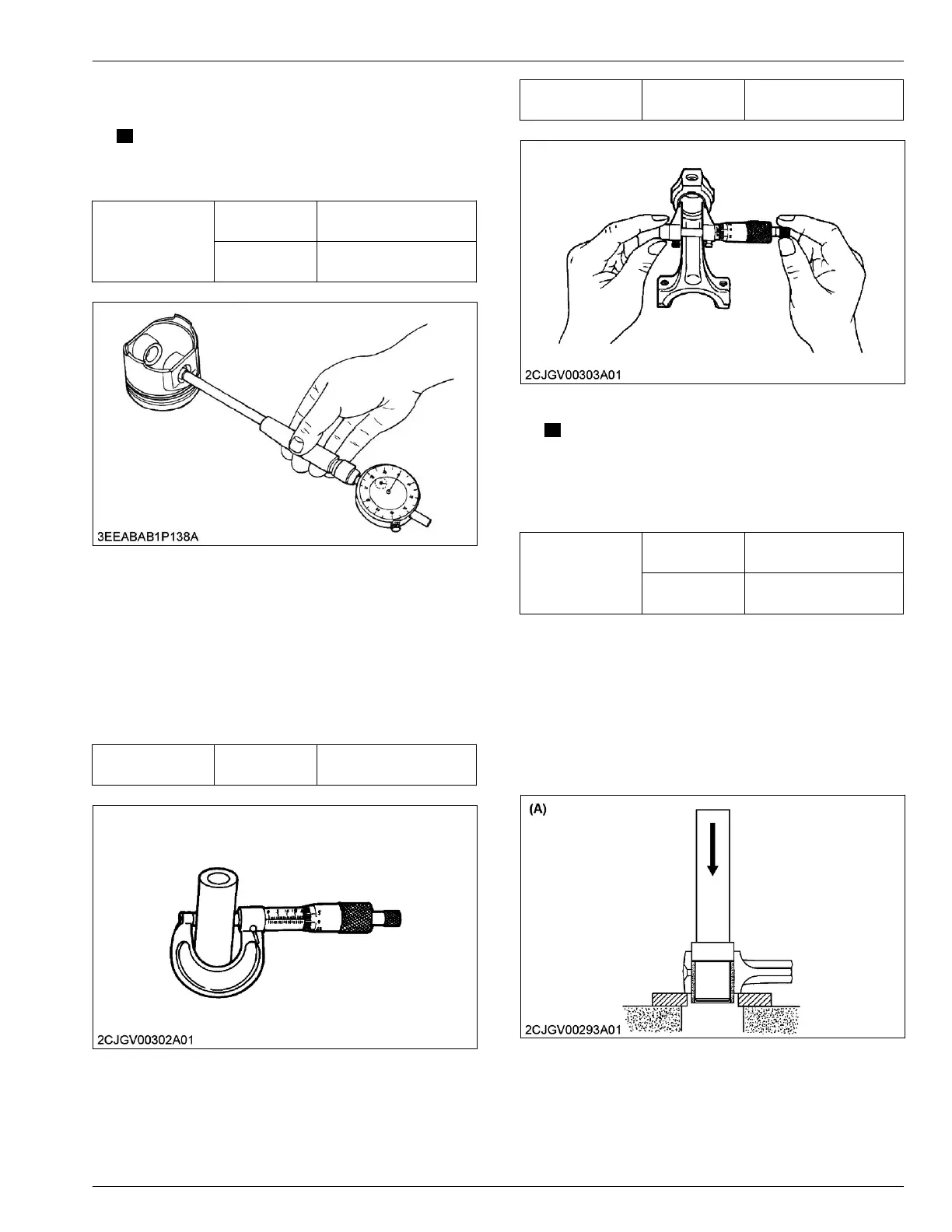

1. Measure

the

piston

pin bore I.D. in the horizontal

and vertical directions with a cylinder gauge.

NOTE

• If the measurement

is more than the service

limit, replace the piston.

Piston pin bore

I.D.

Service specifi-

cation

22.000 to 22.013 mm

0.86615 to 0.86665 in.

Service limit

22.03 mm

0.08673 in.

6.25 Checking oil clearance between

piston pin and small end bushing

Tools required

• Outside micrometer

• Inside micrometer or cylinder gauge

1. Measure the piston pin O.D. at where it contacts the

bushing with an outside micrometer.

Piston pin O.D.

Service specifi-

cation

22.002 to 22.011 mm

0.86622 to 0.86657 in.

2. Measure

the

small

end bushing I.D. at the small

end of connecting rod with an inside micrometer or

cylinder gauge.

Small end bushing

I.D.

Service specifi-

cation

22.025 to 22.040 mm

0.86713 to 0.86771 in.

3. Calculate the oil clearance.

NOTE

• If

the

oil

clearance is more than the service

limit, replace the bushing.

• If the oil clearance is still more than the

service limit, replace the piston pin.

Oil clearance be-

tween piston pin

and small end

bushing

Service specifi-

cation

0.014 to 0.038 mm

0.00056 to 0.0014 in.

Service limit

0.15 mm

0.0059 in.

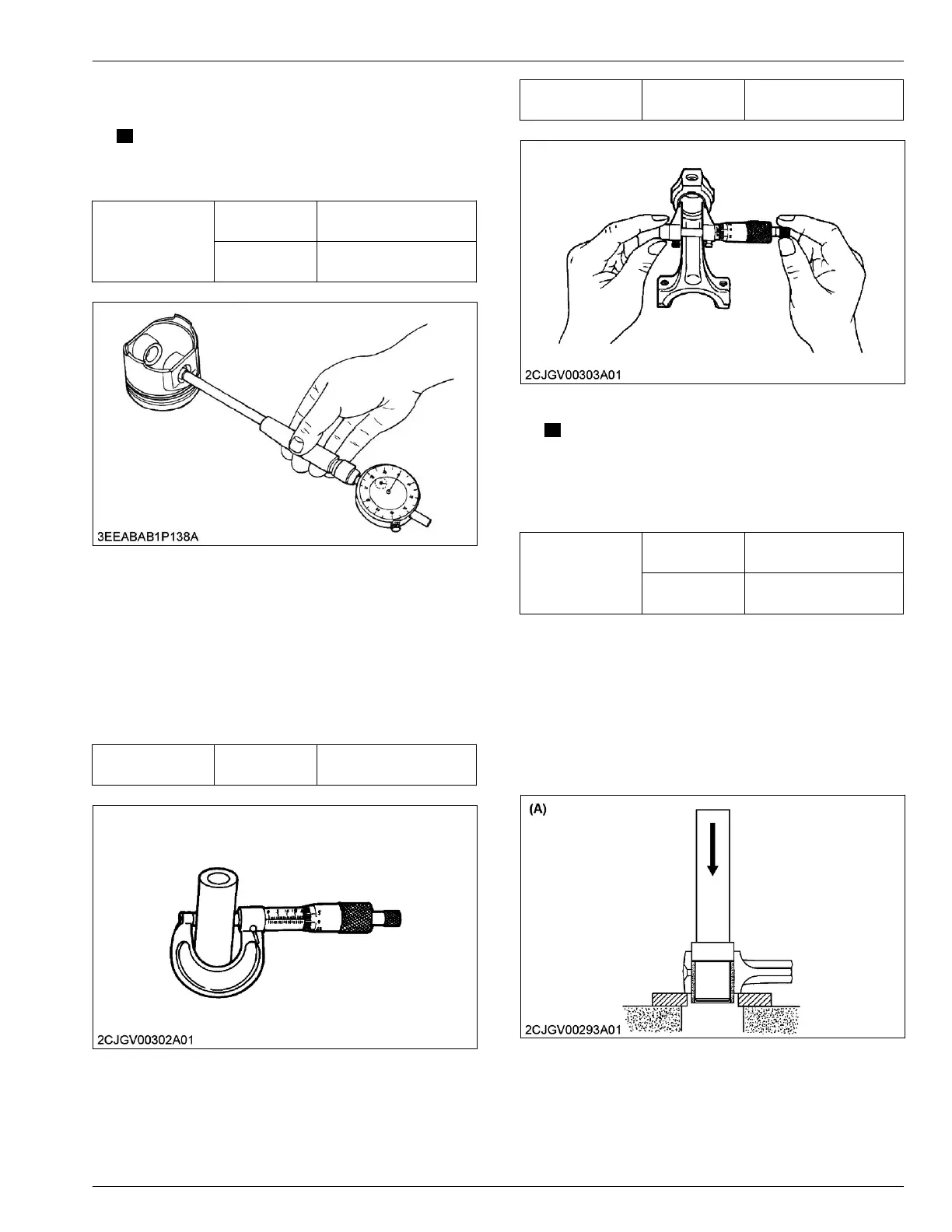

6.26 Replacing small end bushing

Tools required

• Small end bushing replacing tool

Removing small end bushing

1. Press

out the used small end bushing with small

end bushing replacing tool.

(A) Removing direction

Installing small end bushing

1. Clean a new small end bushing and bore.

2. Insert the new small end bushing onto the tool.

SERVICING

6. Servicing 4. ENGINE

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...