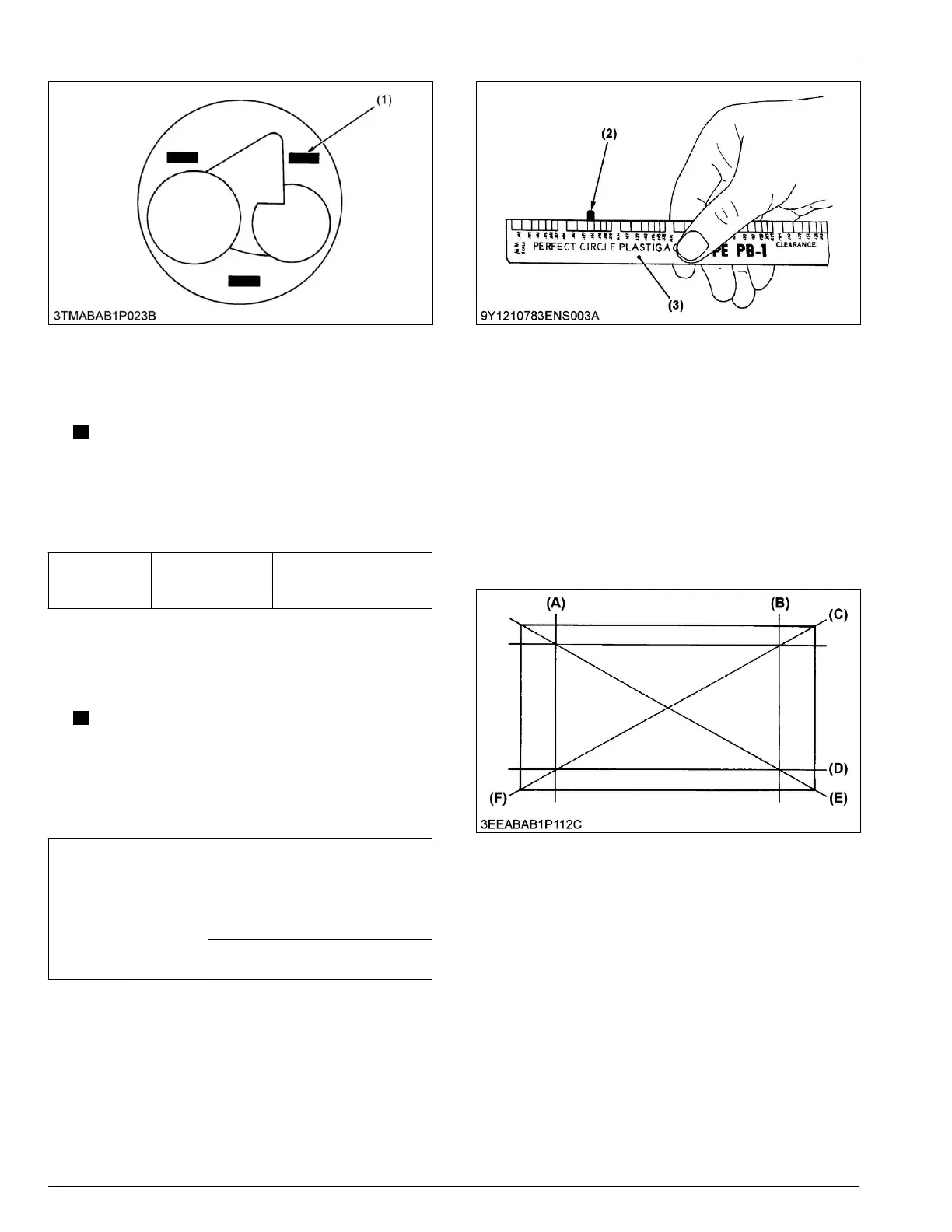

(1) Plastigauge

3. T

ake the piston to an intermediate position, install

the cylinder

head and tighten the cylinder head

mounting screw to the specified torque.

NOTE

• The polished cylinder

head mounting screw

with no marking on the screw head has

possibly used.

• In this case, tighten this screw to the same

torque as normal one.

Tightening tor-

que

Cylinder head

mounting screw

64 to 68 N⋅m

6.5 to 7.0 kgf⋅m

47 to 50 lbf⋅ft

4. Turn the crankshaft so the piston goes through

T.D.C.

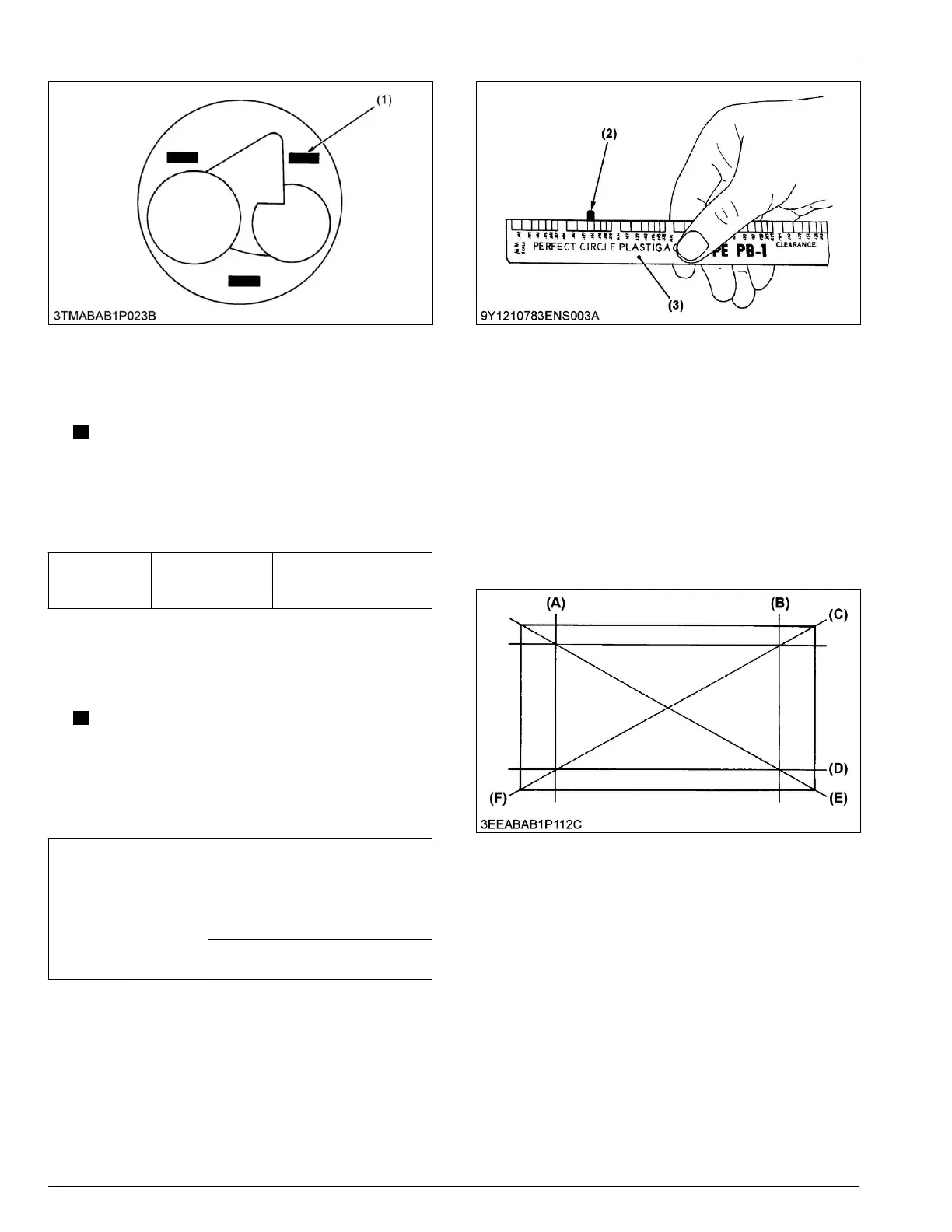

5.

Remove the cylinder head and compare the width

of the crushed plastigauges (2) with the scale (3).

NOTE

• Top clearance

= Width of the crushed

plastigauge (2)

• If they are out of service specification, check

the oil clearance of the crankpin, journal and

piston pins.

Top clear-

ance

Service

specifica-

tion

D1005-E4B/

E4BG

D1105-E4B/

E4BG

V1505-E4B/

E4BG

0.55 to 0.75 mm

0.022 to 0.029 in.

D1305-E4B/

E4BG

0.80 to 1.0 mm

0.032 to 0.039 in.

(2) Crushed plastigauge (3) Scale

6.2 Checking cylinder head surface

flatness

Tools required

• Straightedge

• Feeler gauge

1.

Clean the cylinder head surface.

2. Place a straightedge on the cylinder head's four

sides (A), (B), (C) and (D) and two diagonal (E) and

(F) as shown in the figure.

4. ENGINE

SERVICING

6. Servicing

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...