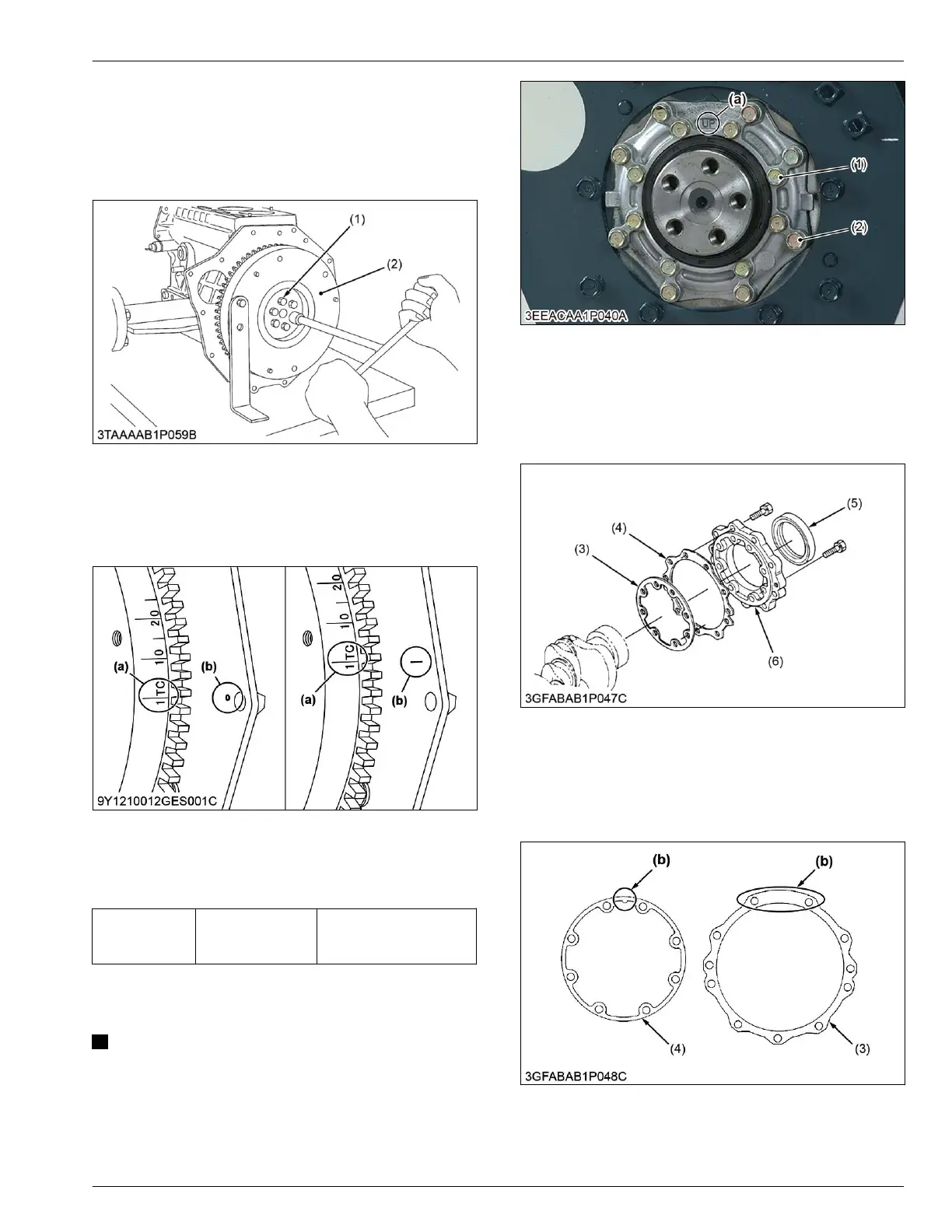

5.24 Removing flywheel

1. Secure the flywheel

to keep it from turning, using a

flywheel stopper.

2. Remove all flywheel screws (1) and then remove

the flywheel (2).

(1) Flywheel screw (2) Flywheel

(When reassembling)

• Align the "1TC"

mark (a) on the outer surface of the

flywheel horizontally with the alignment mark (b) on

the rear end plate. Now fit the flywheel in position.

(a) 1TC mark (b) Alignment mark

• Apply

engine oil to the threads and the undercut

surface of the flywheel screw and fit the screw

.

•

Tighten to the specified tightening torque.

Tightening tor-

que

Flywheel screw

54 to 58 N⋅m

5.5 to 6.0 kgf⋅m

40 to 43 lbf⋅ft

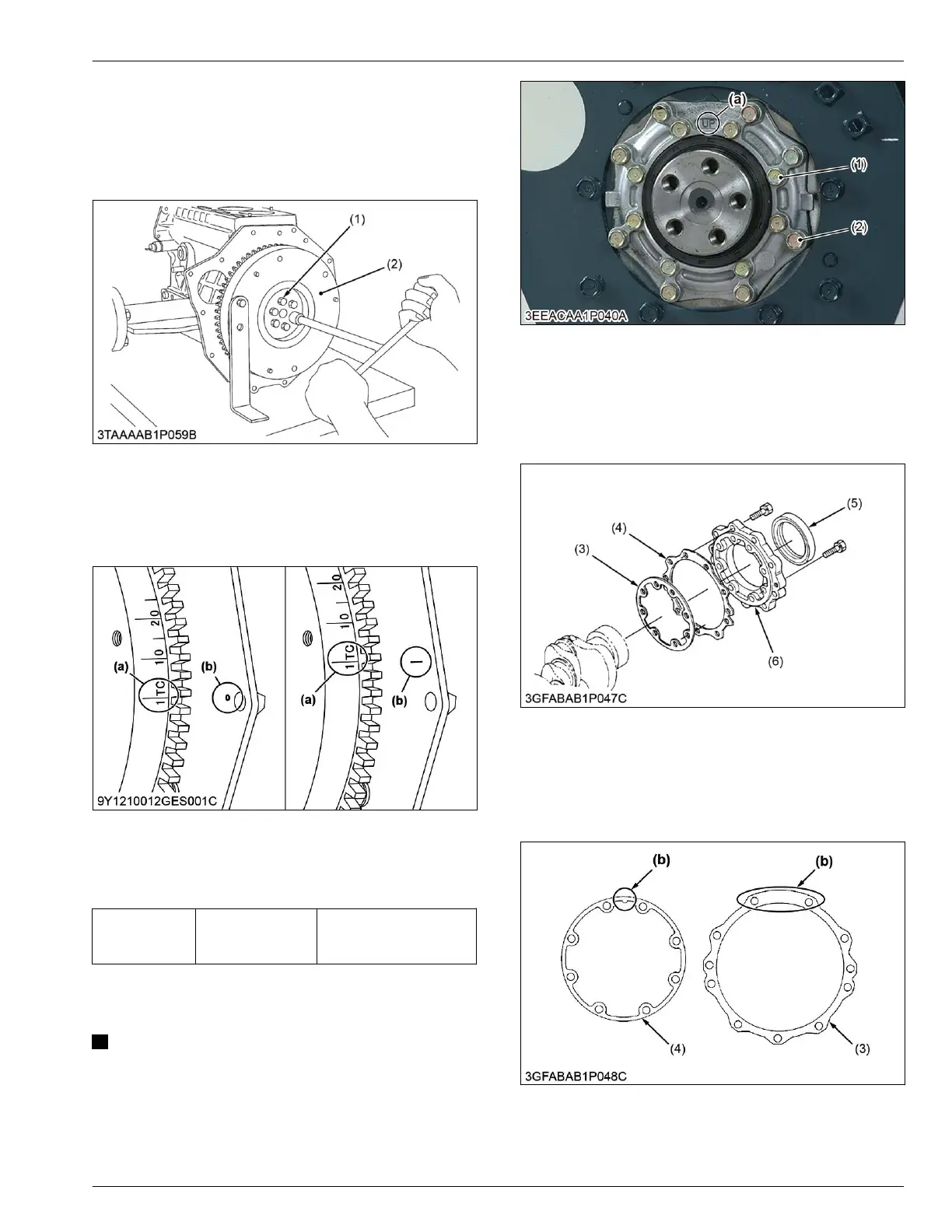

5.25 Removing bearing case cover

IMPORTANT

• The length of

inside screws (1) and outside

screws (2) are different. Do not teke a mistake

using inside screws and outside screws.

(1) Bearing case cover mount-

ing screw (Inside) (Long)

(2) Bearing case cover mount-

ing screw (Outside) (Short)

(a) T

op mark "UP"

1. Remove the bearing case cover mounting screws.

2.

Remove the bearing case cover (6).

(3) Bearing case gasket

(4) Bearing case cover gasket

(5) Oil seal

(6)

Bearing case cover

(When reassembling)

• Fit the bearing

case gasket (3) and the bearing

case cover gasket (4) with correct directions.

(3) Bearing case gasket

(4) Bearing case cover gasket

(b) Upside

•

Install

the bearing case cover (6) to position the

casting mark "UP" on it upward.

SER

VICING

5. Disassembling and assembling 4. ENGINE

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...