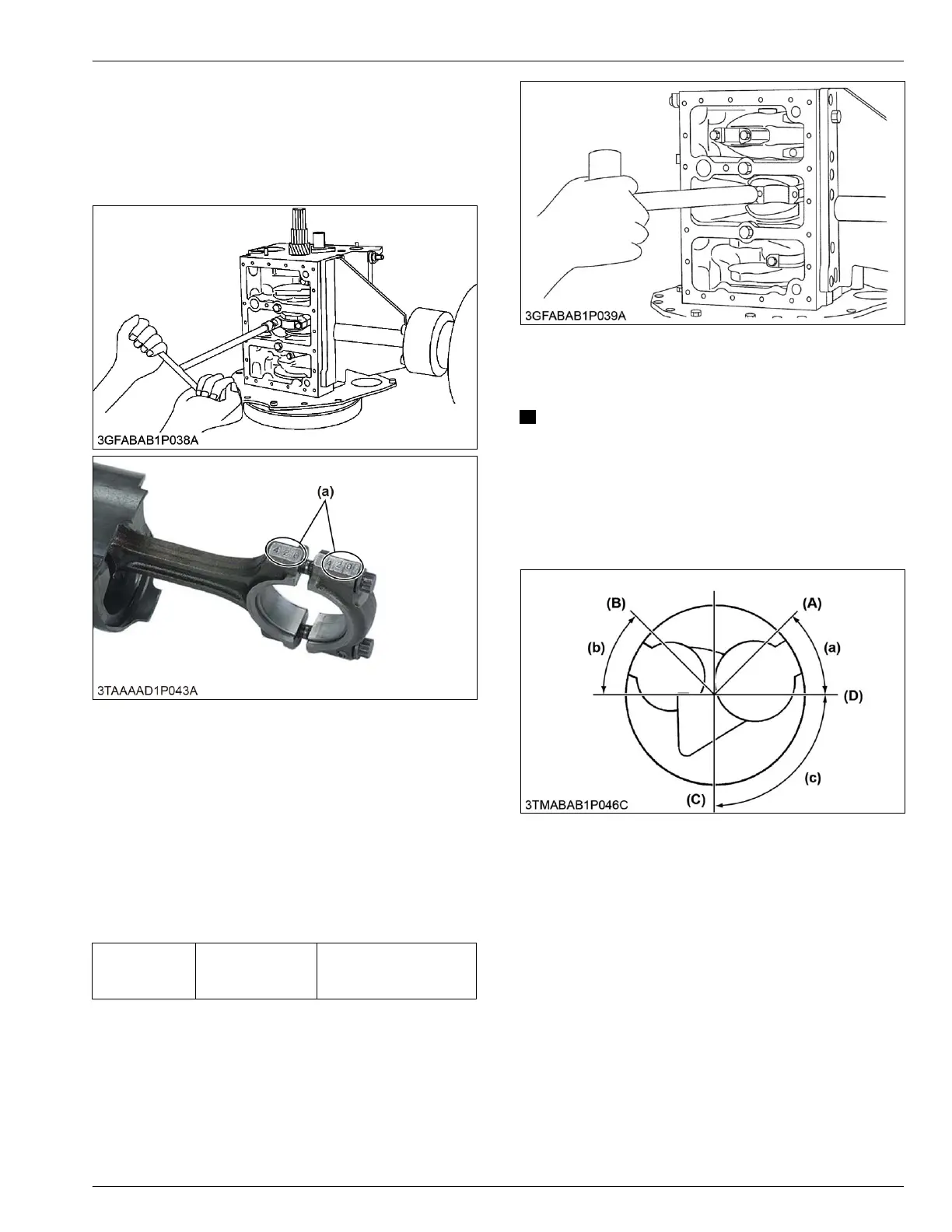

5.21 Removing connecting rod

1. Remove the connecting rod cap.

(When reassembling)

• Align the marks

(a) with each other. (Face the

marks toward the injection pump.)

(a) Mark

• Apply

engine oil to the connecting rod screws and

lightly screw

it in by hand, then tighten it to the

specified torque.

If the connecting rod screw won't be screwed in

smoothly, clean the threads.

If the connecting rod screw is still hard to screw in,

replace it.

• The polished connecting rod screw with no marking

on the screw head has possibly used.

In this case, tighten this screw to the same torque

as normal one.

Tightening tor-

que

Connecting rod

screw

42 to 46 N⋅m

4.3 to 4.6 kgf⋅m

31 to 33 lbf⋅ft

5.22 Removing pistons

1. Turn the flywheel and bring the piston to top dead

center.

2.

Draw out the piston upward by lightly tapping it from

the bottom of the crankcase with the grip of a

hammer.

3. Draw out the other piston in the same method as

above.

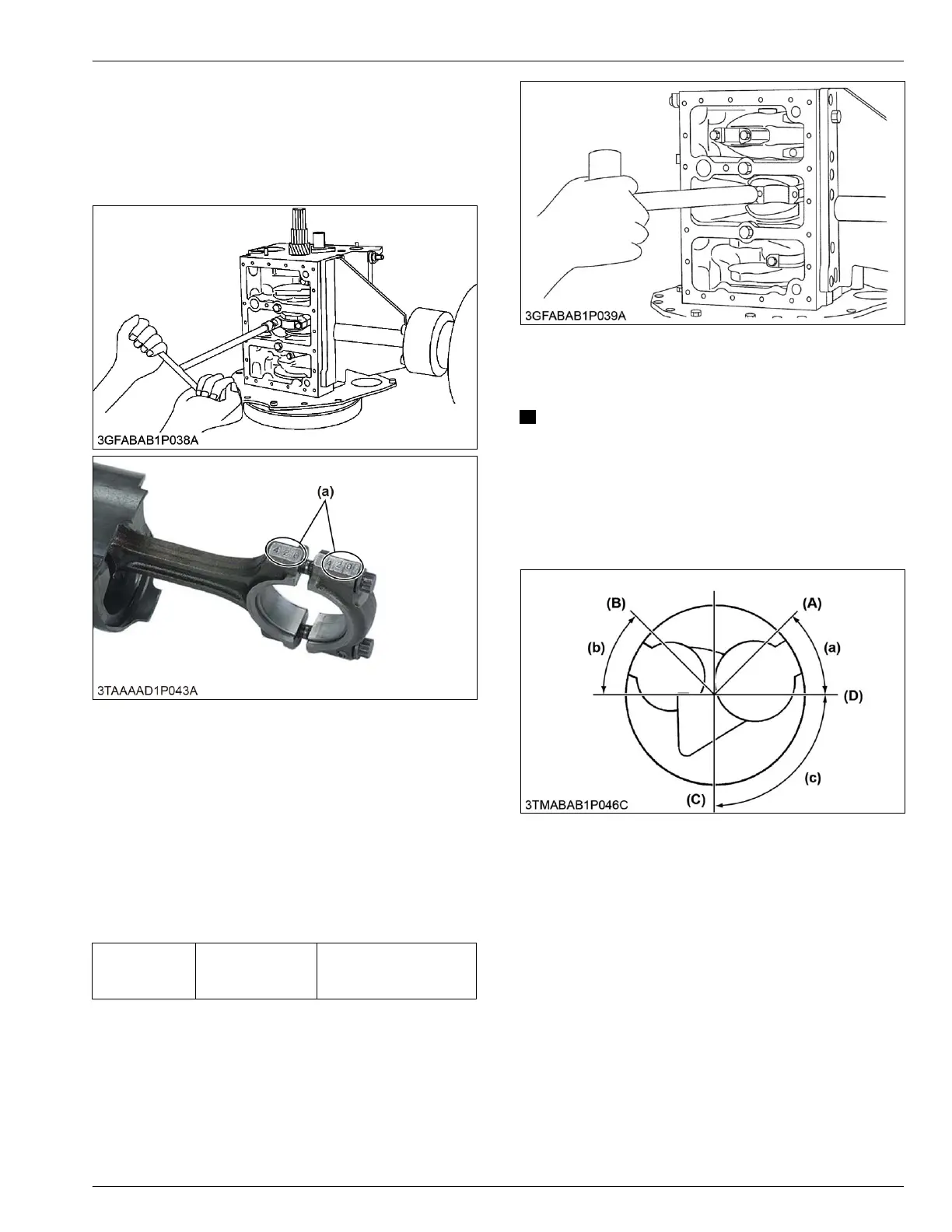

(When reassembling)

IMPORTANT

• Do not change

the combination of cylinder and

piston. Make sure of the position of each piston

by marking. For example, mark "1" on the No.1

piston.

• When installing the piston into the cylinder,

place the gaps of all the piston rings as shown

in the figure.

(A) Top ring gap

(B) Second ring gap

(C) Oil ring gap

(D)

Piston pin hole

(a) 0.79 rad (45°)

(b) 0.79 rad (45°)

(c) 1.6 rad (90°)

• Carefully

insert

the

pistons using a piston ring

compressor (1). Otherwise, their chrome-plated

section may be scratched, causing trouble

inside the cylinder.

SERVICING

5. Disassembling and assembling 4. ENGINE

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...