3. Measure the valve recessing with a depth gauge.

NOTE

• If the measurement

is more than the service

limit, replace the valve.

• If it stays more than the service limit after

you replace the valve, replace the cylinder

head.

Valve recessing

Service specifica-

tion

0.050 (protrusion) to

0.25 (recessing) mm

0.0020 (protrusion) to

0.00098 (recessing) in.

Service limit

0.40 (recessing) mm

0.016 (recessing) in.

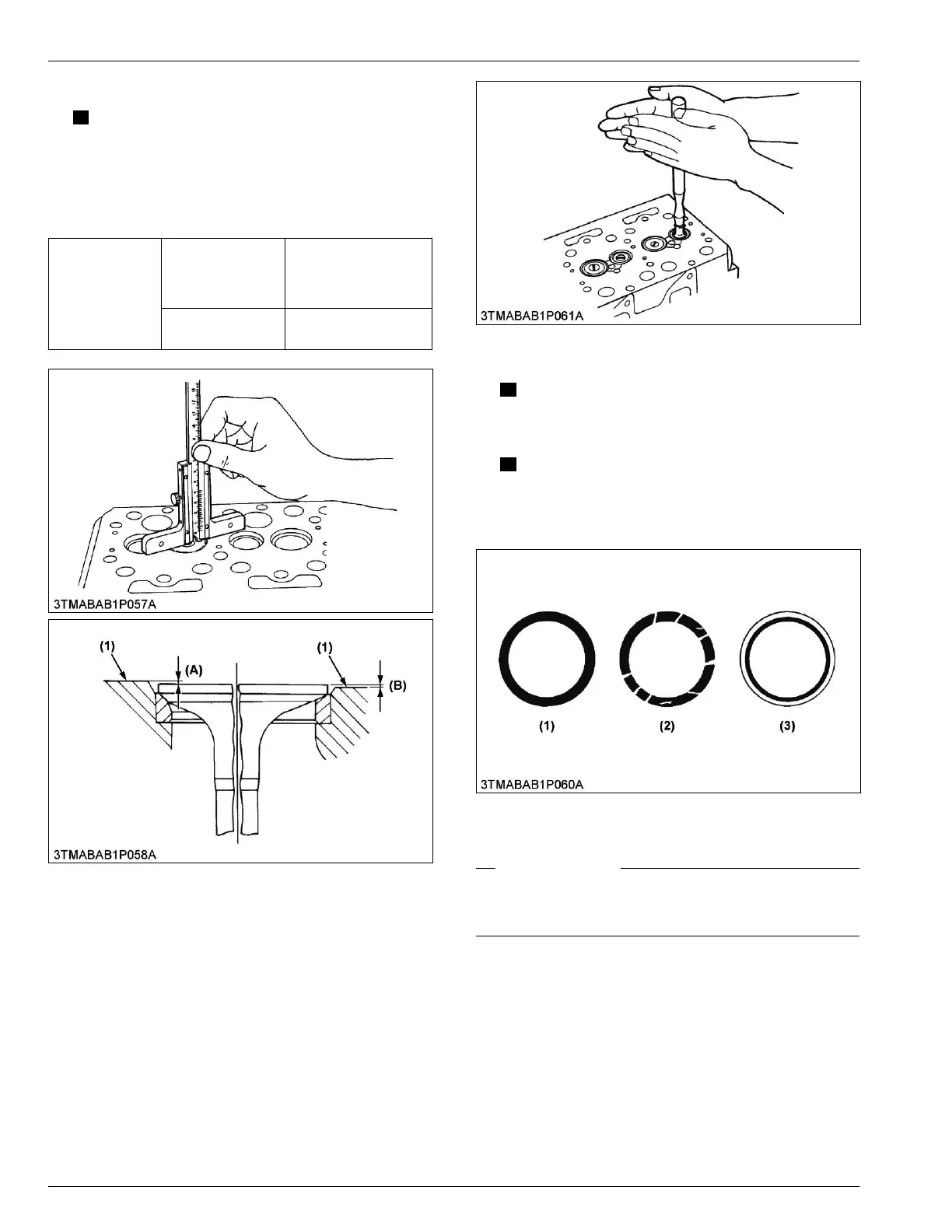

(1) Cylinder head surface

(A) Recessing

(B) Protrusion

6.5 Adjusting valve lapping

T

ools required

• Compound

• V

alve lapping tool

• Prussian Blue

1. Apply the compound equally to the valve lapping

surface.

2. Put the valve into the valve guide. Lap the valve on

its seat with a valve lapping tool.

3. After you lap the valve, clean away the compound

and apply oil, then lap the valve again with oil.

4. Apply Prussian Blue to the contact surface to

measure the seated rate.

NOTE

• If the seated

rate is less than 70%, lap the

valve again.

IMPORTANT

• After you complete

the valve lapping and

assemble the valve, check the valve

recessing and adjust the valve clearance.

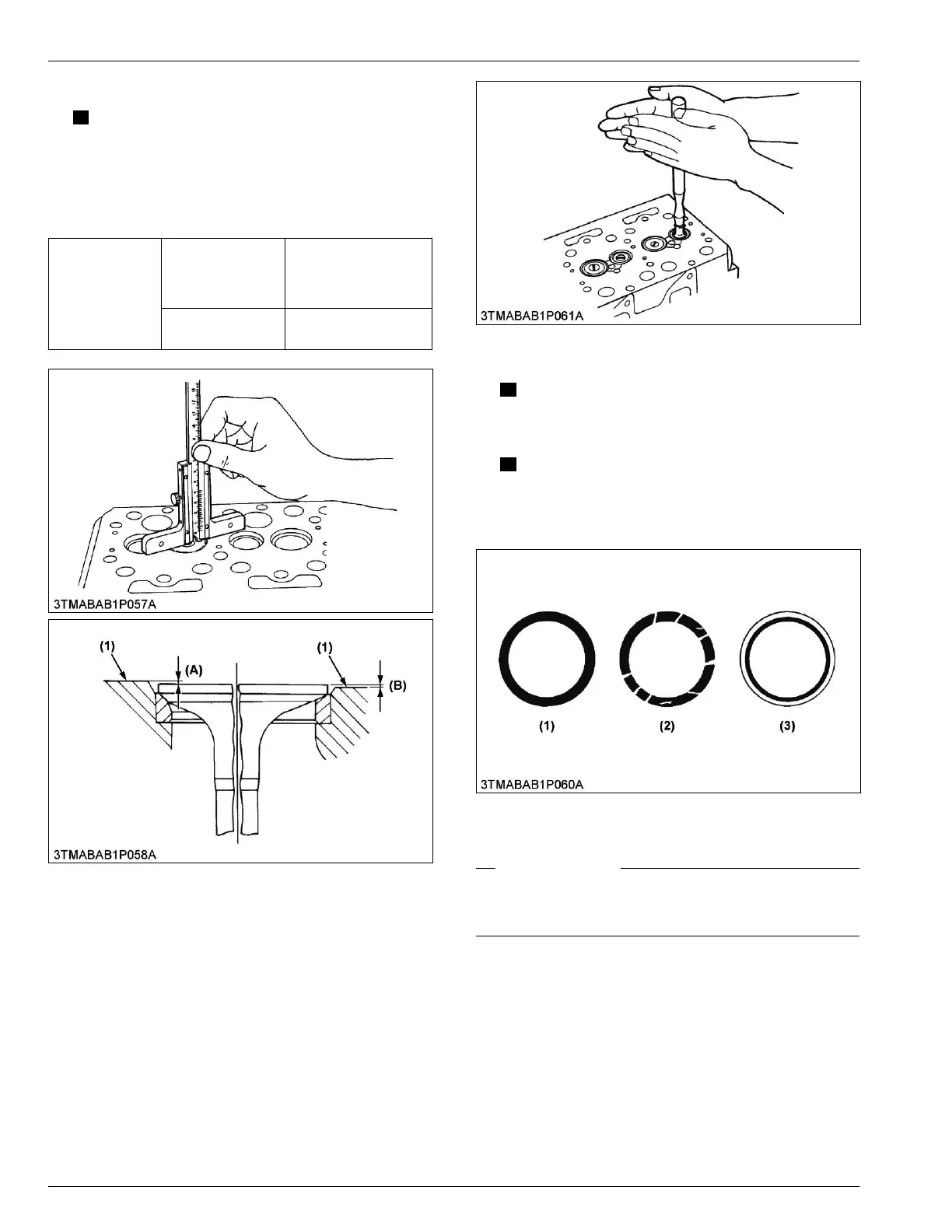

(1) Good

(2) Bad

(3) Bad

RELATED PAGE

10.1 Checking valve clearance on page 3-15

6.4 Checking valve recessing on page 4-51

6.6 Checking clearance between

valve stem and valve guide

Tools required

• Outside micrometer

• Inside micrometer

1.

Remove carbon from the valve guide section.

4. ENGINE

SERVICING

6. Servicing

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...