3. T

urn the flywheel counterclockwise (viewed from

flywheel

side)

until the fuel fills up to the hole of the

delivery valve holder (3) for No. 1 cylinder.

4. After the fuel fills up to the hole of the delivery valve

holder for No. 1 cylinder, turn back (clockwise) the

flywheel around 1.6 rad (90°).

5. Turn the flywheel counterclockwise to set at around

0.44 rad (25°) before T.D.C..

6. Slowly turn the flywheel counterclockwise and stop

turning when the fuel begins to come up, to get the

present injection timing.

7. Check to if the timing angle lines on the flywheel is

aligned with the center of timing window (2).

The flywheel has mark [1TC], [10] and [20] for the

crank angle before the top dead center of No. 1

cylinder.

8. If injection timing is out of adjustment, readjust the

timing with shims.

Injection tim-

ing

(3000 min

-1

(rpm))

Service

Specifica-

tion

D1005-

E4B

0.3011 to

0.3272 rad

(17.25 to 18.75°)

before T.D.C.

Injection tim-

ing

(3200 min

-1

(rpm))

D1005-

E4B

0.3360 to

0.3621 rad

(19.25 to 20.75°)

before T.D.C.

Injection tim-

ing

(3000 min

-1

(rpm))

D1105-

E4B

0.301

1 to

0.3272 rad

(17.25 to 18.75°)

before T.D.C.

Injection tim-

ing

(2600 min

-1

(rpm))

D1305-

E4B

0.2622 to

0.2923 rad

(15.25 to 16.75°)

before T.D.C.

Injection tim-

ing

(2300 min

-1

(rpm))

V15005-

E4B

0.2313 to

0.2574 rad

(13.25 to 14.75°)

before T.D.C.

Injection tim-

ing

(1800 min

-1

(rpm))

D1005-

E4BG,

D1105-

E4BG,

0.2575 to

0.2836 rad

(14.75 to 16.25°)

before T.D.C.

Injection tim-

ing

(1800 min

-1

(rpm))

D1305-

E4BG,

V1505-

E4BG,

0.2487 to

0.2748 rad

(14.25 to 15.75°)

before T.D.C.

12.2 Checking injection pump

NOTE

• Never try to

disassemble the injection pump

assembly. For repairs, you are strongly

requested to contact a Kubota-authorized pump

service shop.

Tools required

• Injection pump pressure tester

Fuel tightness of pump element

1. Remove the engine stop solenoid.

2. Remove the injection pipes and glow plugs.

3.

Install the injection pump pressure tester to the

injection pump.

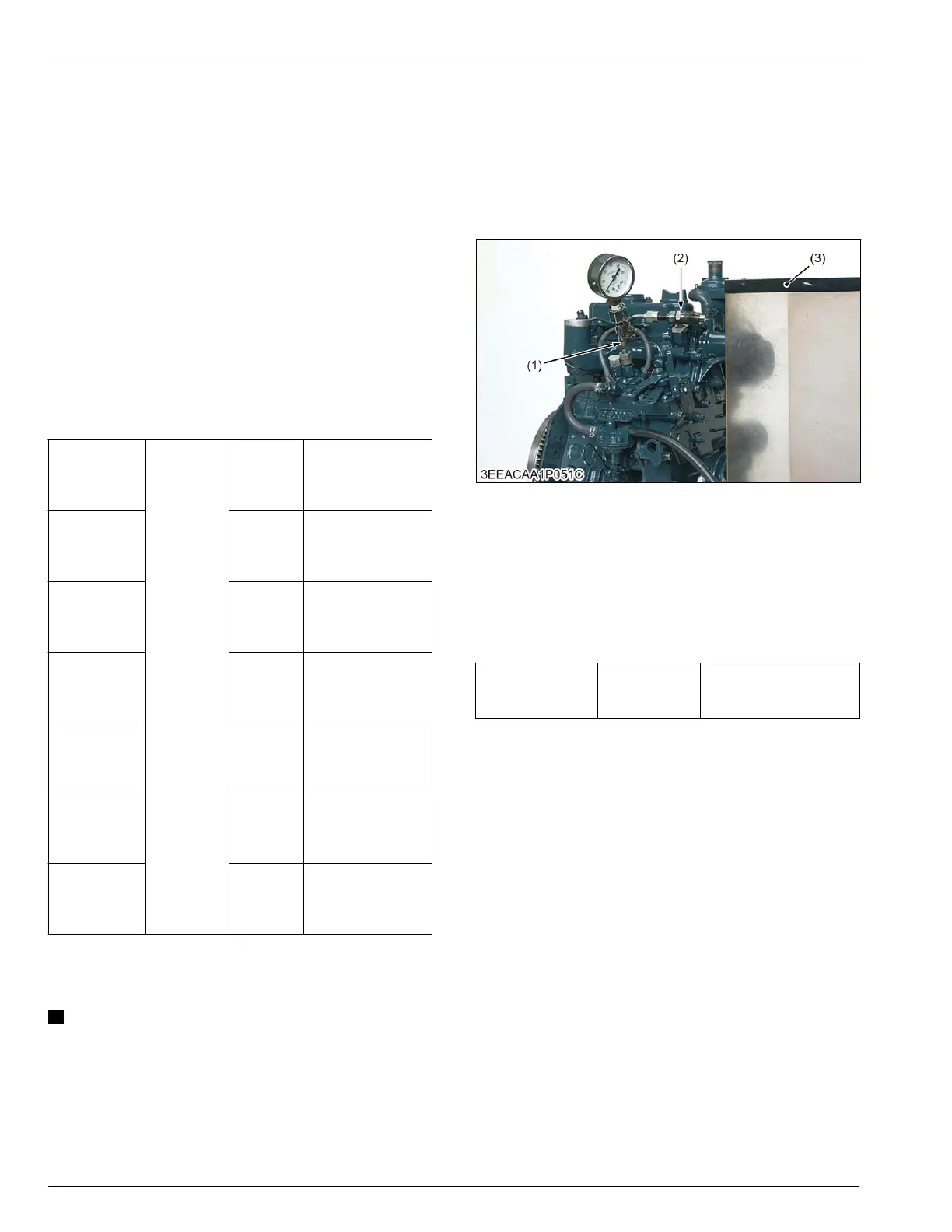

4. Install the injection nozzle (2) jetted with the proper

injection pressure to the injection pump pressure

tester (1).

(1) Injection pump pressure test-

er

(2) Injection nozzle

(3) Protection cover for jetted

fuel

5.

Set

the speed control lever to the maximum speed

position.

6.

Operate the starter to increase the pressure.

7.

If the pressure can not reach the service limit,

replace the pump with new one or repair with a

Kubota-authorized pump service shop.

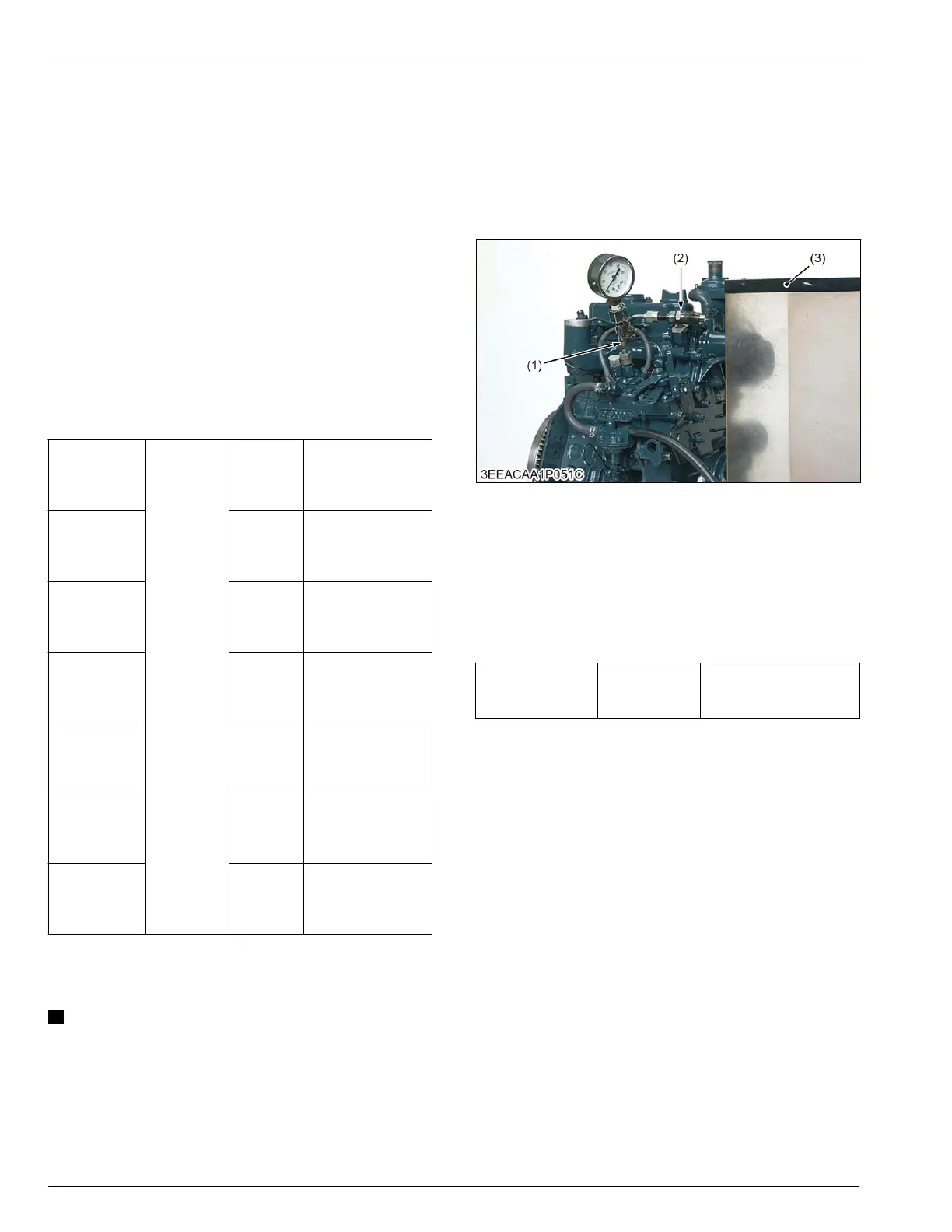

Fuel tightness of

pump element

Service limit

13.73 MPa

140.0 kgf/cm

2

1991 psi

Fuel tightness of delivery valve

1. Remove the engine stop solenoid.

2. Remove the injection pipes and glow plugs.

3.

Set a pressure tester to the fuel injection pump.

4. Install the injection nozzle (2) jetted with the proper

injection pressure to the injection pump pressure

tester (1).

3. MAINTENANCE

CHECK AND MAINTENANCE

12. Check points of every 3000 hours

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...