• Apply

engine oil to the oil seal (5) lip and be careful

that it is not rolled when installing.

•

T

ighten the bearing case cover mounting screws

with even force on the diagonal line.

• Tighten to the specified tightening torque.

Tightening tor-

que

Bearing case cov-

er mounting screw

10.8 to 12.2 N⋅m

1.10 to 1.25 kgf⋅m

7.96 to 9.04 lbf⋅ft

RELATED PAGE

6.30 Checking side clearance of crankshaft on page

4-64

5.26 Removing crankshaft assembly

(except D1305-E4B/E4BG)

IMPORTANT

• Be careful to

protect crankshaft bearing 1 from

scratches, caused by the crank gear, etc.. (Wrap

the gear in vinyl tape, etc.)

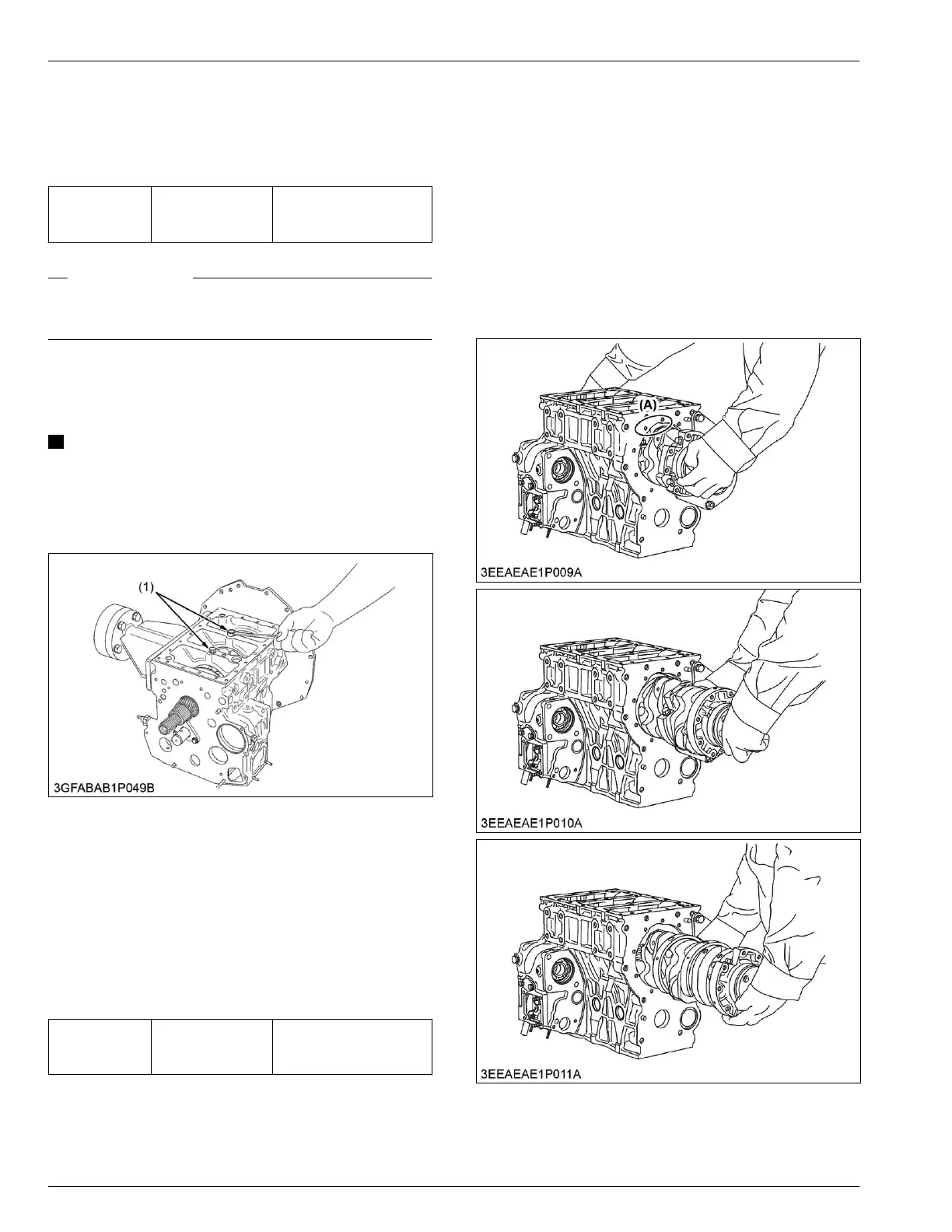

1. Remove the main bearing case screw 2 (1).

(2) Main bearing case screw 2

2. Pull out the crankshaft assembly.

(When reassembling)

• Clean

the oil

passage of the crankshaft with

compressed air.

• Apply oil to the main bearing case screw 2 (1).

• Install the crankshaft assembly, aligning the screw

hole of main bearing case with the screw hole of

crankcase.

• Tighten to the specified tightening torque.

Tightening tor-

que

Main bearing case

screw 2

49 to 53 N⋅m

5.0 to 5.5 kgf⋅m

37 to 39 lbf⋅ft

5.27 Removing crankshaft assembly

(D1305-E4B/E4BG)

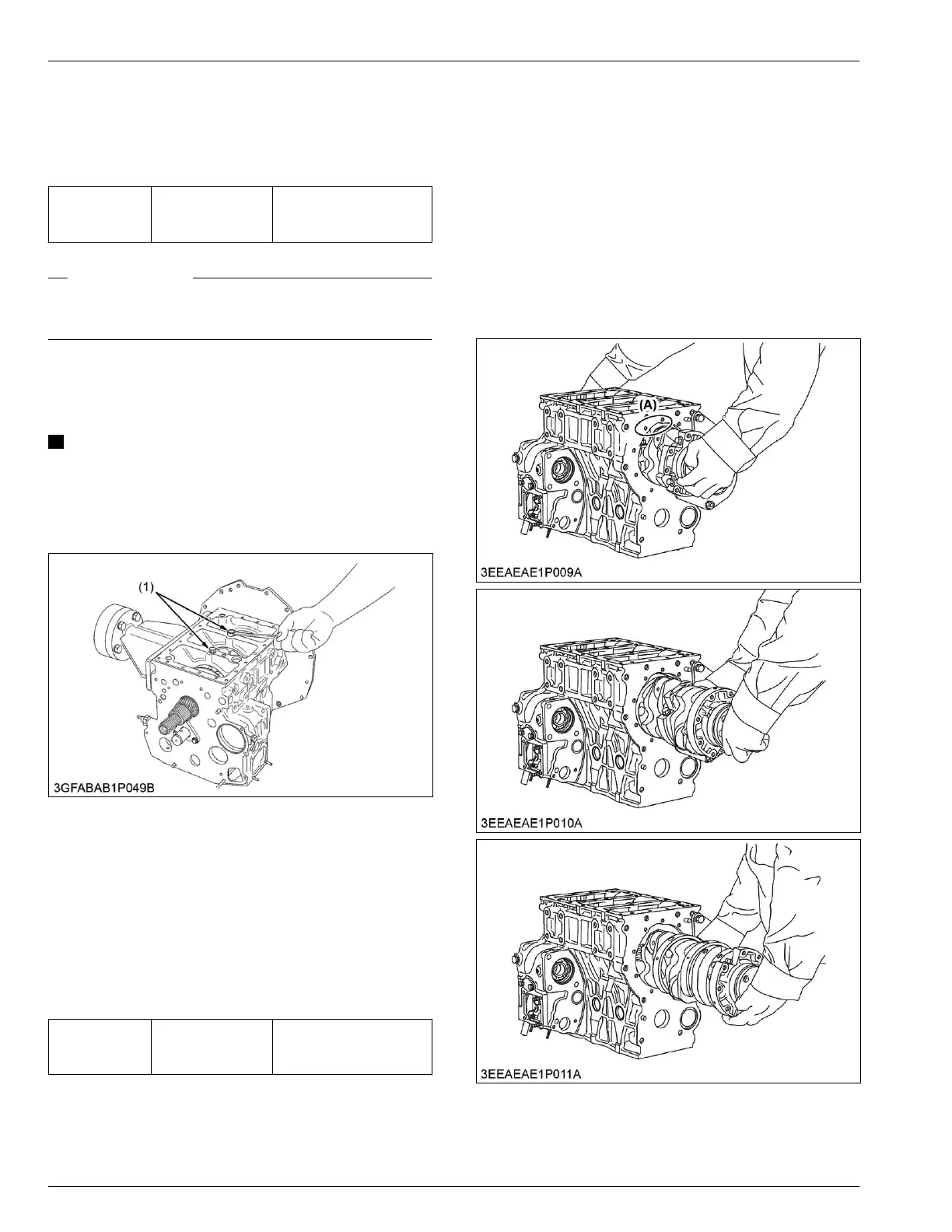

1. Remove the main bearing case screw 2.

2. T

urn the crankshaft to set the crankpin of the third

cylinder to the "A". Then draw out the crankshaft

until the crankpin of the second cylinder comes to

the center of the third cylinder.

3. Turn the crankshaft by 2.09 rad (120°)

counterclockwise to set the crankpin of the second

cylinder to the "A". Draw out the crankshaft until the

crankpin of the first cylinder comes to the center of

third cylinder.

(A) Cut place for removing and

installing the crankshaft

4. Repeat

the these

steps to draw out all the

crankshaft.

4. ENGINE

SERVICING

5. Disassembling and assembling

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...