6.13 Checking oil clearance between

rocker arm and rocker arm shaft

Tools required

• Inside micrometer

• Outside micrometer

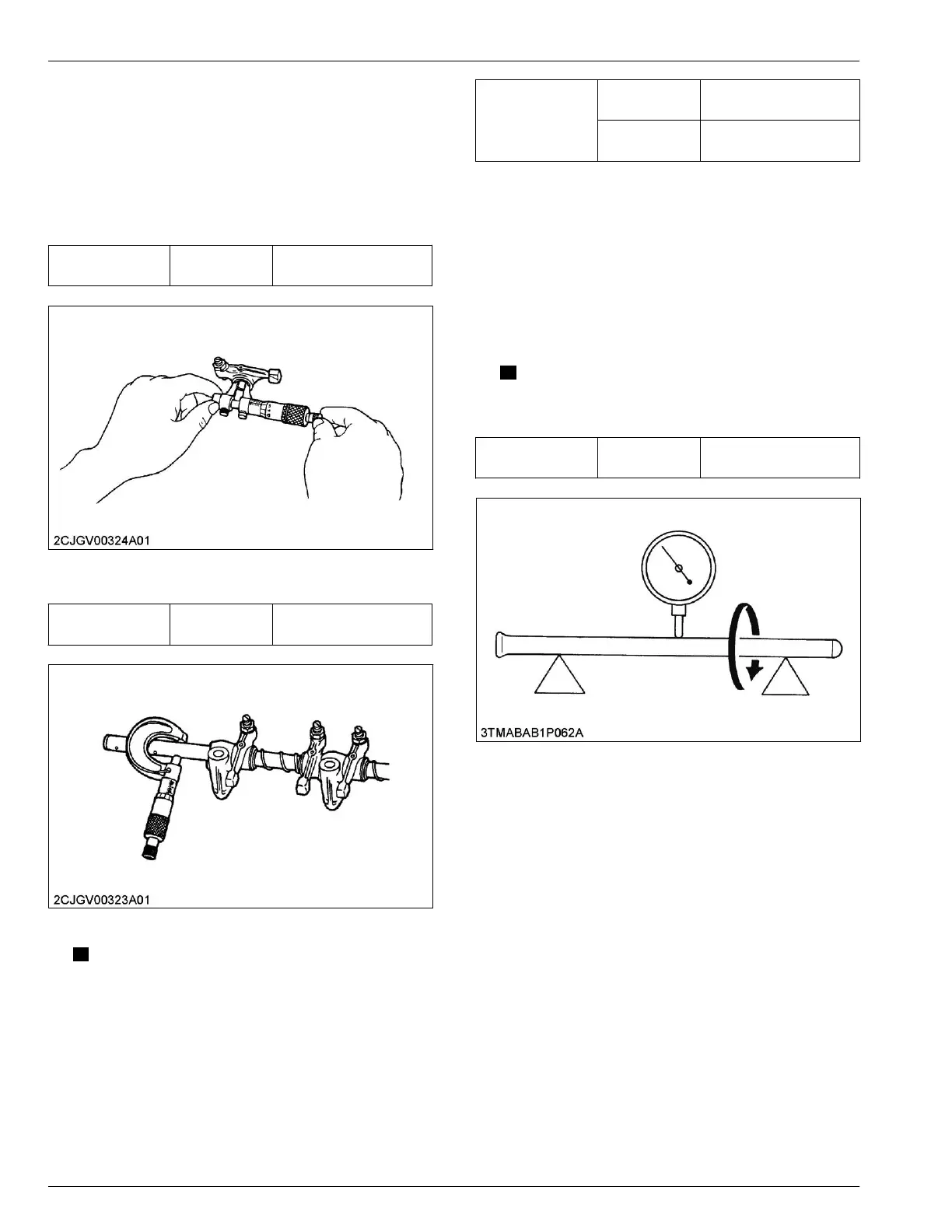

1.

Measure the rocker arm I.D. with an inside

micrometer.

Rocker arm I.D.

Service specifi-

cation

12.000 to 12.018 mm

0.47244 to 0.47314 in.

2. Measure the rocker

arm shaft O.D. with an outside

micrometer.

Rocker arm shaft

O.D.

Service specifi-

cation

11.973 to 11.984 mm

0.47138 to 0.47181 in.

3. Calculate the oil clearance.

NOTE

• If

the

oil

clearance is more than the service

limit, replace the rocker arm and measure

the oil clearance again.

• If the oil clearance stays more than the

service limit, replace the rocker arm shaft

also.

Oil clearance be-

tween rocker arm

and rocker arm

shaft

Service specifi-

cation

0.016 to 0.045 mm

0.00063 to 0.0017 in.

Service limit

0.10 mm

0.0039 in.

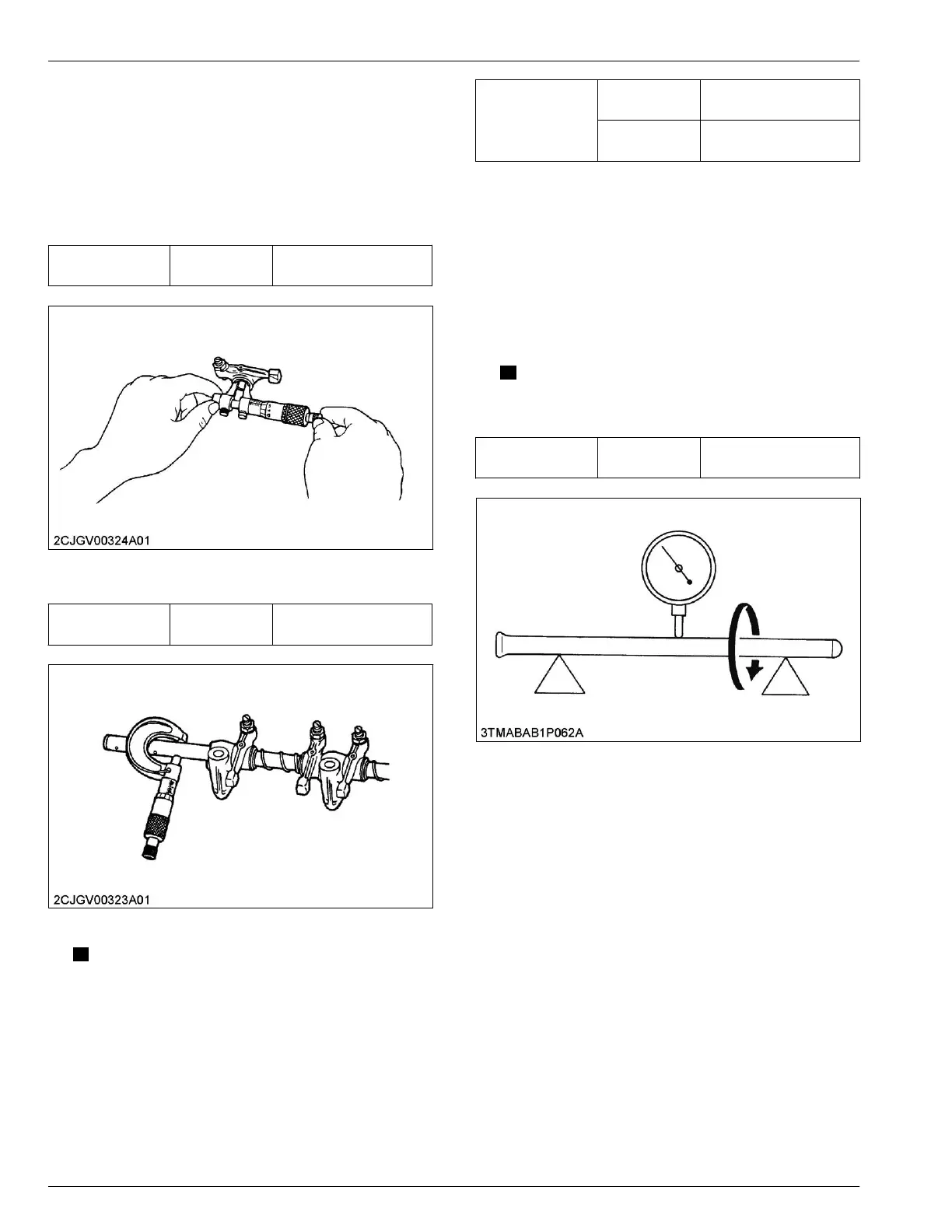

6.14 Checking push rod alignment

Tools required

• V blocks

• Surface plate

•

Dial gauge

1. Put the push rod on V blocks.

2. Measure the push rod alignment.

NOTE

• If the measurement

is more than the service

limit, replace the push rod.

Pushrod alignment Service limit

0.25 mm

0.0098 in.

6.15 Checking oil clearance between

tappet and tappet guide bore

Tools required

• Outside micrometer

• Cylinder gauge

4. ENGINE

SER

VICING

6. Servicing

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...