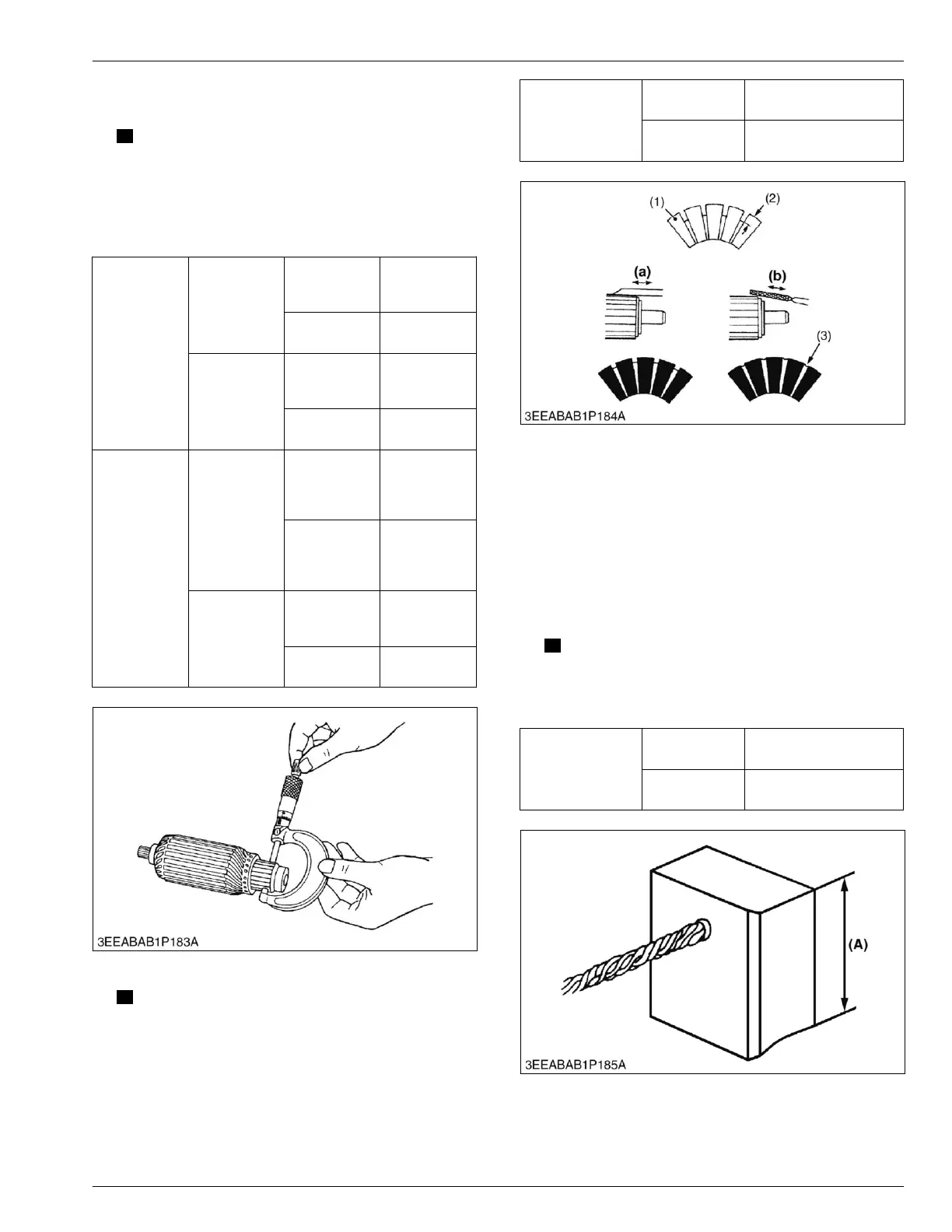

3. Measure

the

commutator

O.D. with an external

micrometer at several points.

NOTE

• If the minimum

O.D. is less than the service

limit, replace the armature assembly.

• If the difference of the O.D.'s more than the

service limit, correct the commutator on a

lathe to the service specification.

Commutator

O.D.

Service speci-

fication

Electromag-

netic drive

type

28.0 mm

1.10 in.

Gear reduc-

tion type

30.0 mm

1.18 in.

Service limit

Electromag-

netic drive

type

27.0 mm

1.06 in.

Gear reduc-

tion type

29.0 mm

1.14 in.

Difference of

O.D.'s

Service speci-

fication

Electromag-

netic drive

type

Less than

0.05 mm

Less than

0.002 in.

Gear reduc-

tion type

Less than

0.02 mm

Less than

0.0008 in.

Service limit

Electromag-

netic drive

type

0.4 mm

0.02 in.

Gear reduc-

tion type

0.05 mm

0.002 in.

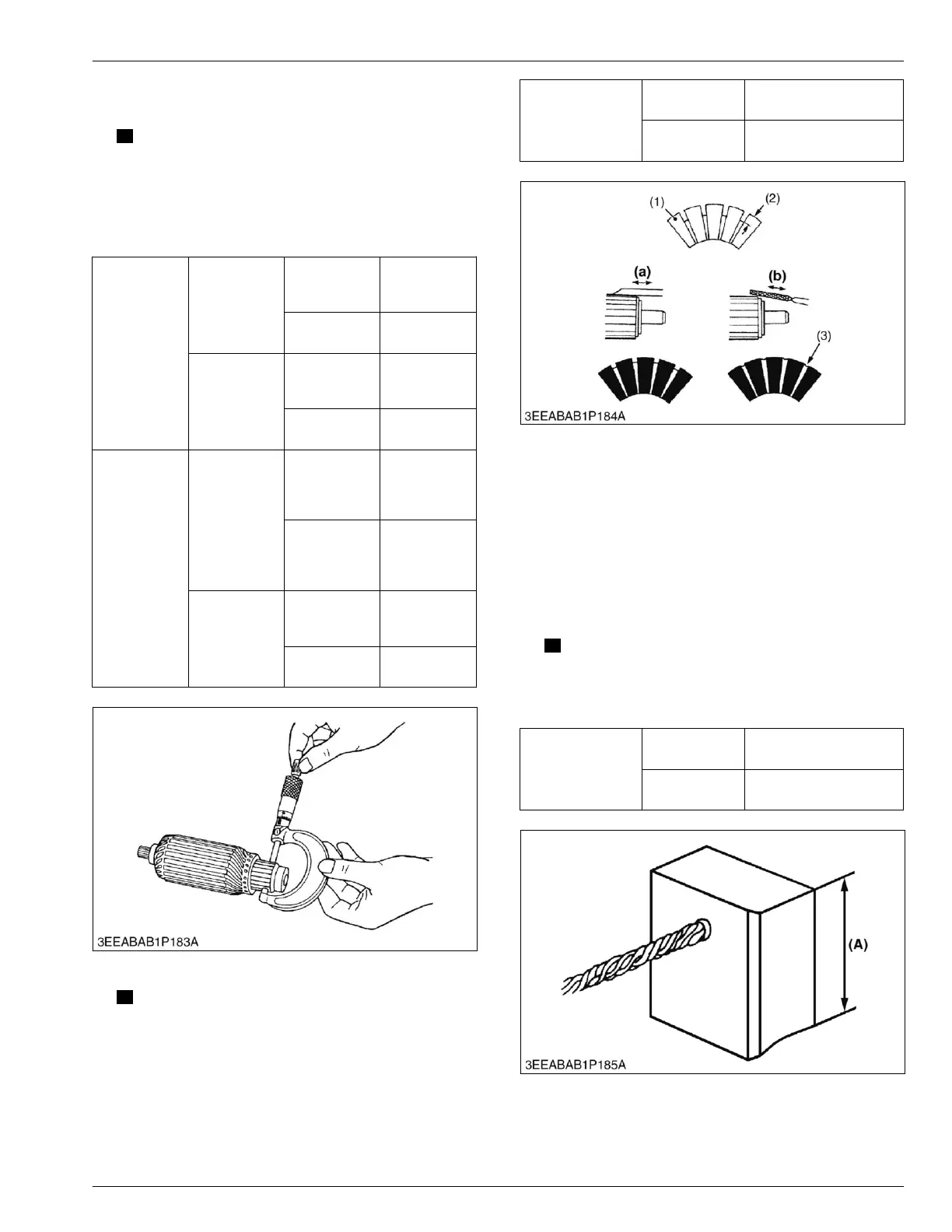

4. Measure the mica undercut.

NOTE

• If the undercut is less than the service limit,

correct it with a saw blade. Chamfer the

segment edges.

Mica undercut

Service specifi-

cation

0.50 to 0.80 mm

0.020 to 0.031 in.

Service limit

0.20 mm

0.0079 in.

(1) Segment

(2) Depth of mica

(3) Mica

(a) Good

(b) Bad

6.44 Checking brush wear of starter

Tools required

• Vernier caliper

•

Emery paper (#300 or above)

1. Measure the brush length (A) with a vernier caliper.

NOTE

• If the length

is less than the service limit,

replace the yoke assembly and brush holder

assembly.

Brush length (A)

Service specifi-

cation

16.0 mm

0.630 in.

Service limit

10.5 mm

0.413 in.

(A) Brush length

2. After

you replace the brush, put an emery paper

(#300 or

above) on the commutator and correct the

contact position.

SERVICING

6. Servicing 4. ENGINE

05-E4B SERIES,05-E4BG SERIES

Loading...

Loading...