55

LeeBoy Model 8510E Conveyor Paver 5-13

Maintenance

Change Engine Oil and Filter

The engine lubrication oil and oil lter must be changed

at the same time.

To change the engine lubrication oil:

1. Park the paver on a level surface and turn off the

engine.

Change the engine lubrication oil

while the engine is WARM, not hot. Hot oil can cause

serious personal injury.

2. If needed, wait until the engine lubrication oil has

cooled a little. Oil should be warm, not hot.

3. Locate oil drain hose on right side of the paver.

4. Place a container large enough to hold 15 quarts

(14.2 liters) of oil underneath the drain hose.

5. Remove cap on end of the hose and drain all engine

oil into the container.

6. Reinstall cap back onto the hose and reinsert hose

back into place.

7. Fill the engine with 15 quarts (14.2 liters) of oil at the

oil ll cap.

8. Check oil level using the oil dipstick.

9. Dispose of used oil in accordance with local and

federal environmental laws.

DO NOT change the engine lubrication

oil lter while the engine is running. Serious engine

damage will occur.

Use the following procedures to change the oil lter:

1. Wipe the area around the oil lter and its mounting

base with a clean cloth.

2. Place the empty container under the lter element.

3. Use a lter removal wrench to remove the lter,

turning counterclockwise.

4. Drain and discard the oil lter in accordance with

Step 9 above..

NOTE: Discard the used rubber gasket with the lter

element.

5. Wipe inside the oil lter head using a clean, lint-free

cloth.

6. Rub a little oil on the rubber gasket area of the new

lter element.

7. Fill the new lter with fresh oil.

8. Install the new lter element onto the lter head.

Carefully tighten the lter (by hand only).

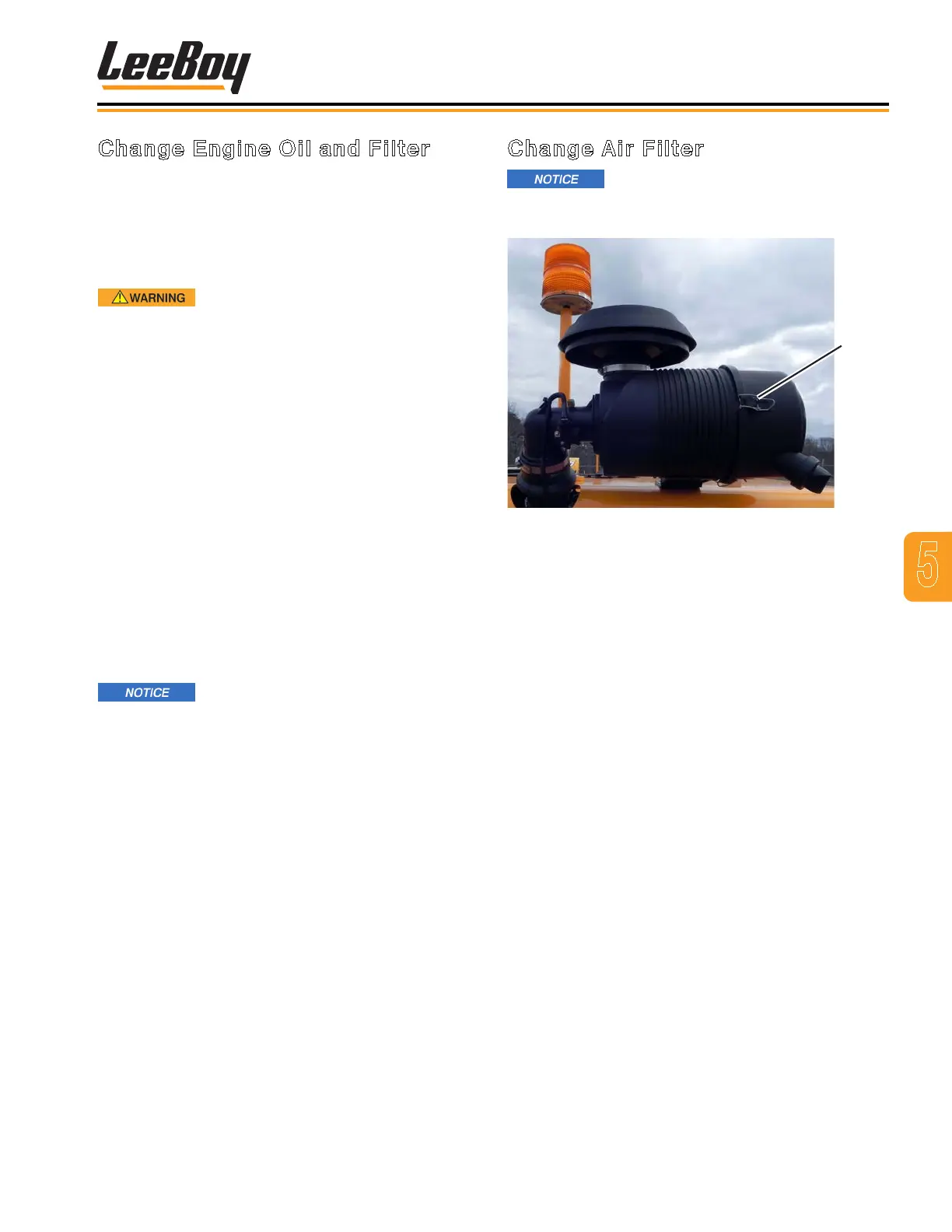

Change Air Filter

Never operate the engine without an

air lter installed. Severe damage to the machine will

occur.

Figure 5-14. Air Filter Cover

To change the air lter elements:

1. Unclamp and remove air lter cover. (Figure 5-14)

2. Remove the primary and secondary air lter

elements. Discard.

3. Clean the inside of the air cleaner body with a clean

cloth.

4. Install new air lter elements inside the canister.

5. Reclamp cap onto the air lter cover.

6. Check clamps to ensure lter elements are tight and

lter elements are making proper contact.

7. Start engine. If engine does not run smoothly,

recheck lter element contact.

8. Install new air lter elements inside the canister.

9. Reclamp cap onto the air lter cover.

10. Check clamps to ensure lter elements are tight and

lter elements are making proper contact.

11. Start engine. If engine does not run smoothly,

recheck lter element contact.

Loading...

Loading...