4-24 LeeBoy 8510E Conveyor Paver

Operation

Hopper Wings

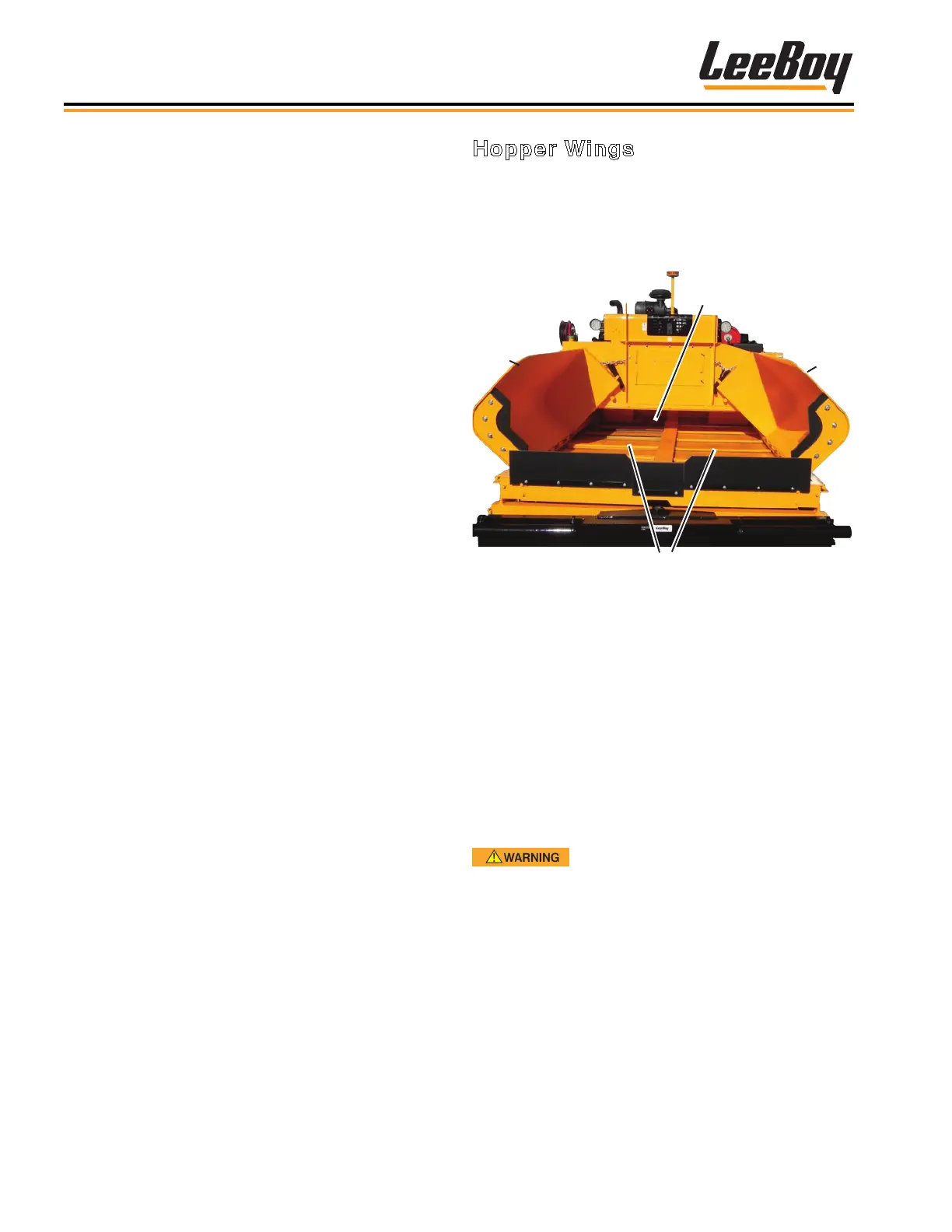

The hopper wings are hydraulically opened so the

hopper can be lled with paving material. (Figure 4-39)

Conveyor paddles in the bottom move the asphalt back

to the auger, where the mix ows through the cut-off

gates to the screed.

2

1

1

Figure 4-39. Hopper

1 - Hopper Wings

2 - Auger

3 - Conveyors

To operate the hopper wings:

1. Push the hopper wings lever to OUT on the manifold

to fold out hopper wings. (Pages 3-6 and 3-7)

2. Be sure the hopper wings are completely extended

before receiving paving material from the truck.

3. Push the hopper wings lever to IN to close the

hopper wings.

DO NOT fold in the hopper wings when

the hopper is full of asphalt. DO NOT fold in the

hopper until the material truck has moved completely

away from the paver.

NOTE: Allow the screed (and screed extension) to

heat 15 minutes before beginning to pave.

Lower the screed two inches off the ground

while heating to prevent cold air and wind

from affecting the heating process.

To operate the electric screed heating system:

1. Start the paver and idle until the engine reaches

normal operating temperature.

2. Set the throttle on the PV480 display to PAVE (1800

RPMs). Do not exceed 1800 RPMs.

3. Raise the screed plate one or two inches off the

ground.

4. Turn the electric heat control box power ON by

ipping the power switch up. (Figure 4-38)

5. Press the Start Heat button.

6. The HEAT ON indicator light will illuminate and stay

on as long as the element is heating the screed.

(The factory-set heat cycle is 20 minutes, which

should generate enough heat to begin the paving

process. Operating in cold temperatures may affect

the screed plate temperature slightly.)

7. If the heat cycle has completed but the screed

plates still require heating, restart the cycle by

repeating Step 5.

Loading...

Loading...