55

LeeBoy Model 8510E Conveyor Paver 5-33

Maintenance

Conveyor Switch Replacement

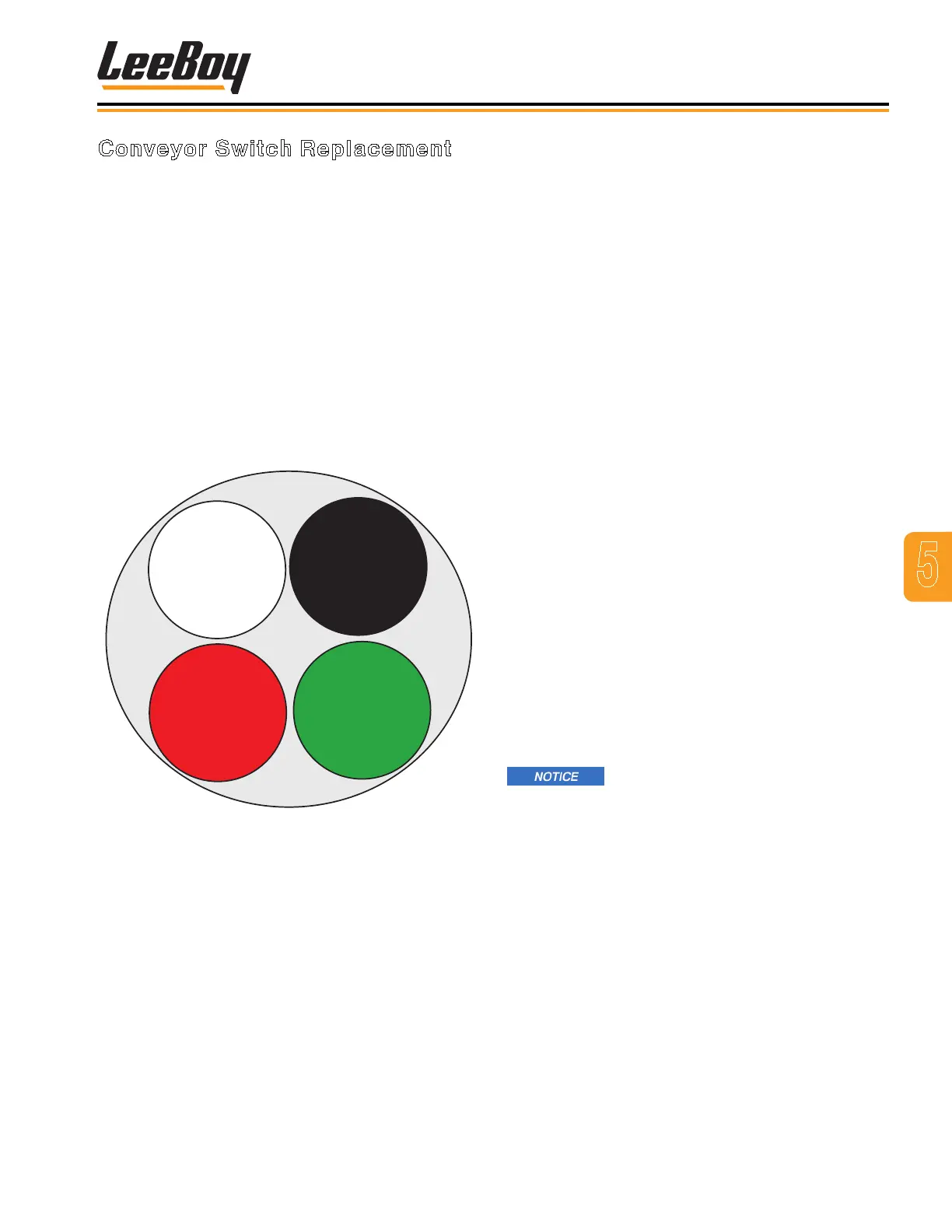

If you need to replace the conveyor switches, follow

these instructions, using the color codes for wiring

(Figure 5-45) to ensure the conveyor switches on the

conveyor ap are wired correctly:

1. Raise the conveyor ap 6-1/2 to 7 inches (16.5 to

17.8 cm) from the bottom of the tank mount support.

2. With the switch installed and the conveyor paddle

hanging down:

• Using a multimeter, measure the ohms across

the black and white wires.

• Using a multimeter, measure the ohms across

the red and green wires.

4

WHITE

3

BLACK

1

RED

2

GREEN

Figure 5-45. Conveyor Switch Wiring

3. Wire the switch using the wires that show continuity.

4. Repeat Steps 2 - 3 for the second switch.

NOTE: The switches are sealed and potted,

therefore, they are not serviceable.

Winterizing for Storage

Perform the following procedures to prepare the

machine for winterizing and storage.

1. Store the machine in a dry, protected area:

• Cover seat with plastic. Place a “DO NOT

OPERATE” tag on the main control panel.

• Cover all exposed control panels with tarps or

plastic.

• Ensure all cab doors and windows are closed

and seal properly.

• Replace worn or damaged decals if needed.

2. Inspect the machine thoroughly and repair worn or

damaged parts. Inspect all hoses, couplers, ttings

and cylinders. Tighten loose ttings and replace any

worn hoses found.

3. Lubricate all grease points:

• Coat all exposed cylinder shafts with lithium-

based grease.

• Ensure all exposed threads are lubricated.

• Ensure cables are lubricated and move freely.

• If the machine has high- and low-speed chains,

be sure they are oiled.

4. Check air lter. Clean or replace air lter elements if

needed.

5. Check engine oil level and ll if needed.

6. Check hydraulic oil sight gauge and ll if needed.

Hydraulic oil that is contaminated

must be drained, the lter elements replaced and

the hydraulic tank relled. Failure to perform this

maintenance procedure if needed could result in

premature failure of the pumps or motors.

Loading...

Loading...