5-16 LeeBoy Model 8510E Conveyor Paver

Maintenance

Hydraulic System

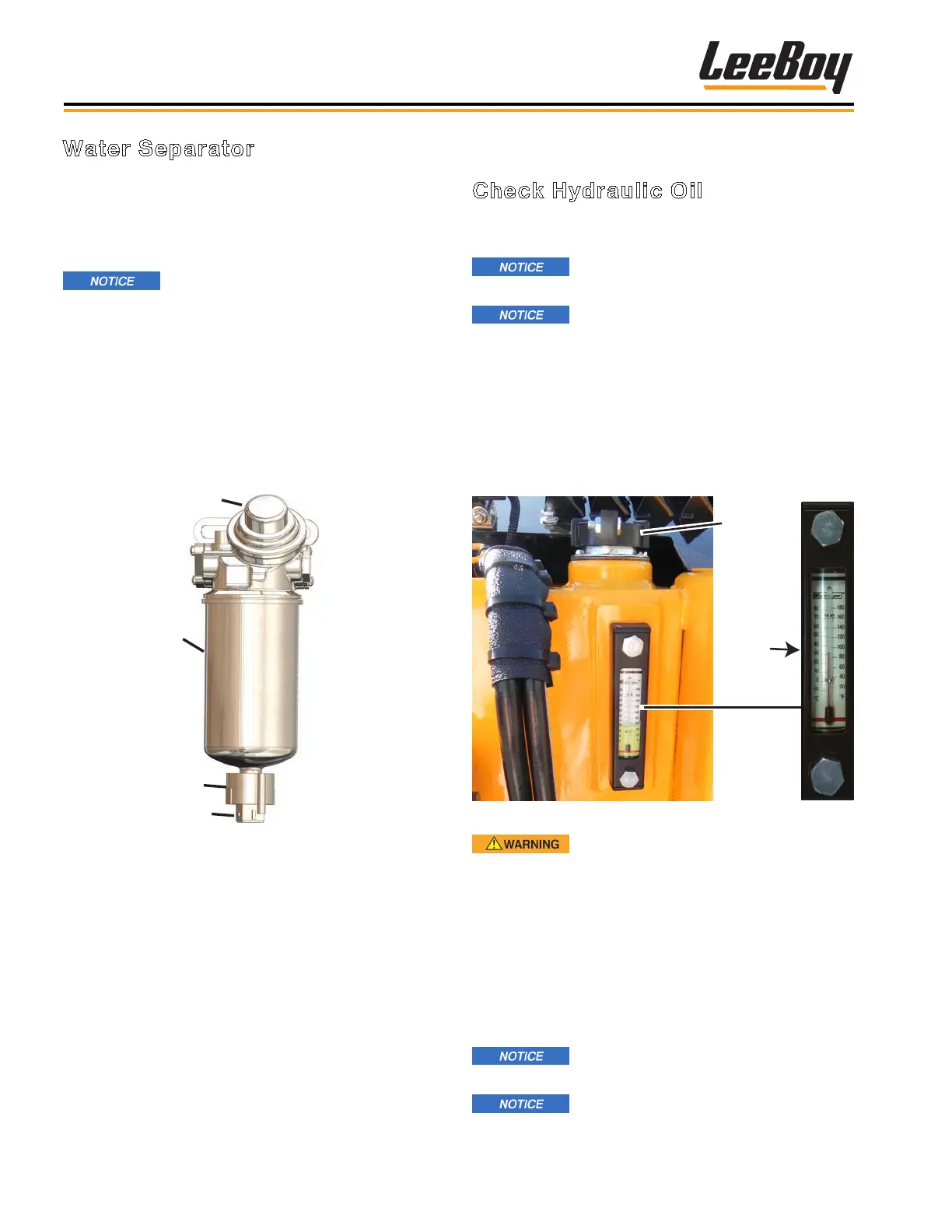

Check Hydraulic Oil

The hydraulic motors and hydraulic cylinders use the

same hydraulic oil reservoir and hydraulic oil supply.

Take care when working with the

hydraulic system to ensure it is completely clean.

Never allow the hydraulic oil level to

fall too low. Pump damage will occur.

Check the hydraulic reservoir oil level daily using the

sight gauge on the left side of the paver. (Figure 5-19)

Check the hydraulic oil level when the hydraulic oil is at

normal operating temperature for an accurate reading.

If the hydraulic oil level falls below the bottom line (red or

black in color), add more hydraulic oil.

Hydraulic

Fill Cap

Sight

Gauge

Fill

Line

Figure 5-19. Hydraulic Oil Cap and Sight Gauge

DO NOT loosen or remove the

hydraulic oil ll cap when the hydraulic oil is hot.

Always loosen the cap slowly to relieve any pressure

in the hydraulic oil reservoir.

• Slowly unscrew the hydraulic oil ll cap and add

hydraulic oil. (Figure 5-19)

• DO NOT use unltered hydraulic oil.

• Check the hydraulic oil level using the sight gauge.

• Keep the hydraulic oil lled to the correct level.

DO NOT overll the hydraulic oil

reservoir.

Leeboy uses a lead-detection dye that

may turn the hydraulic oil a slight yellow tint.

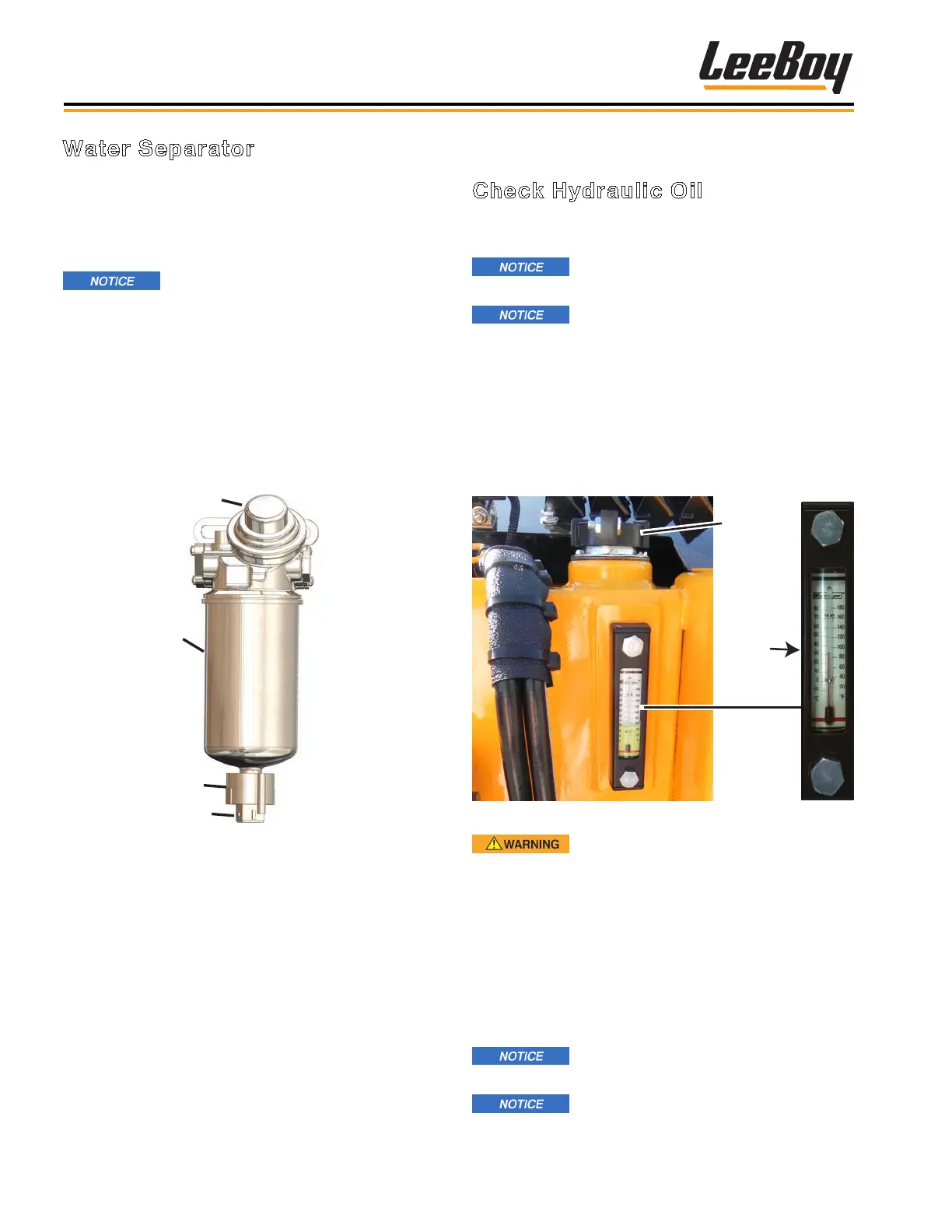

Water Separator

Water and dirt that gets into fuel settles into the water

separator. (Figure 5-18) As it collects, a red oat rises.

When the oat reaches the line on the separator, an

error code will appear on the PV480 digital display. It is

important to drain it immediately.

If you run out of fuel, it is important

to pump the water separator to prime fuel injection

lines. Failure to do so can adversely affect

performance.

To drain the water separator:

1. Pull retainer clip from plug to disconnect the

harness.

2. Unplug the harness, then unscrew the plug.

3. Drain and reinsert components.

1

2

3

4

Figure 5-18. Water Separator

1 - Pump

2 - Filter Body

3 - Plug

4 - Clip

To clean the water separator:

1. Follow the previous steps for draining the water

separator.

2. Loosen and remove the lter body and clean it with

light oil.

3. Reinsert and tighten.

Loading...

Loading...