5-22 LeeBoy Model 8510E Conveyor Paver

Maintenance

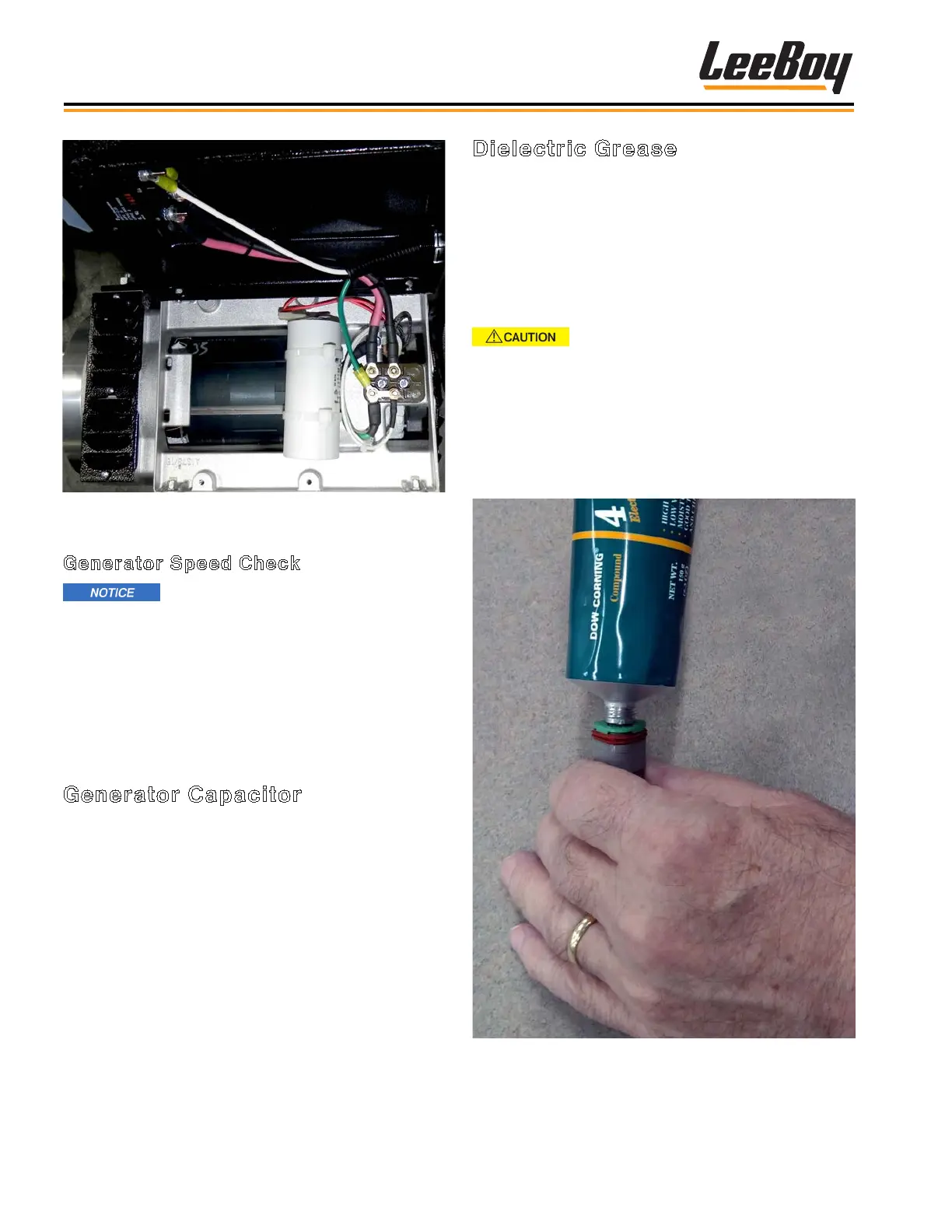

Figure 5-26. Generator

Generator Speed Check

The generator should never be

operated at a speed of 3800 RPMs or greater.

A voltmeter set to read frequency (Hz) can be used to

test generator speed. When the engine is running at

1800 - 2200 RPMs, the generator should operate at 60

Hz. Make certain that the paver engine is running at

1800 - 2200 RPMs and the hydraulic temperature is at

normal operating levels.

Generator Capacitor

The generator capacitor controls and regulates voltage

while the machine operates. If the capacitor fails, the

voltage will drop below normal or no output at all. It is

located under the generator cover.

If experiencing a drop in voltage, replacing the capacitor

will help determine if the capacitor is at fault.

To perform this procedure:

1. Shut down the machine.

2. Detach the wires on top of the capacitor.

3. Remove the capacitor and replace with new one.

4. Reattach wires.

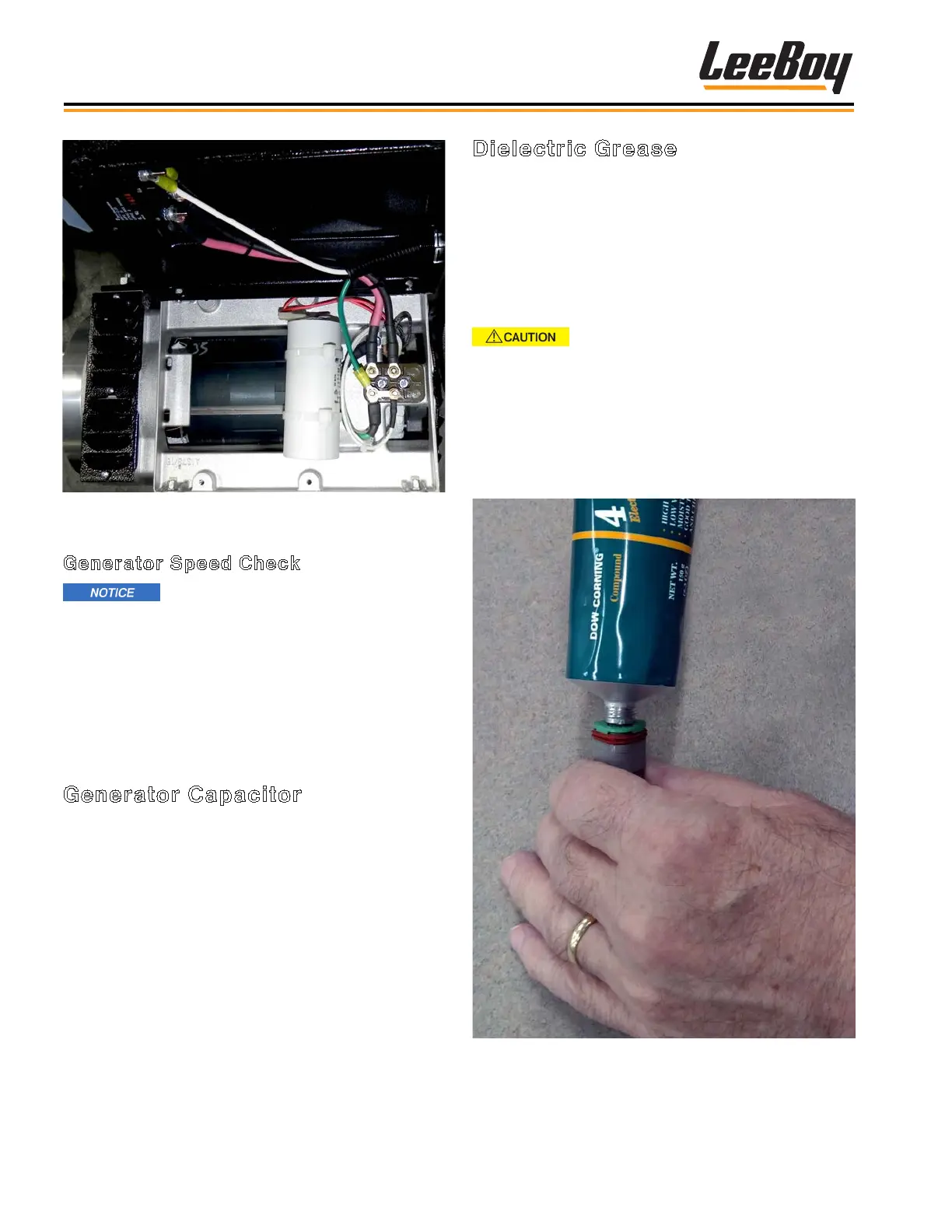

Dielectric Grease

Dielectric grease is a nonconductive, insulating

compound applied to electrical connectors. When

applied correctly, a high-quality dielectric grease

displaces debris and moisture in the connector. The

proper application of dielectric grease lls any gaps

between pins or in the connector which prevents debris

and moisture from creating corrosion of the electrical

components.

Equipment damage can occur if using

low-quality, incompatible dielectric grease.

If not applied or incorrectly applied, corrosion can result

that causes rapid increase in resistance, intermittent

connections, overheating, and a variety of electrical

problems. Numerous electrical issues throughout the

machine can be avoided by the proper application and

use of dielectric grease.

Figure 5-27. Correct Application of Dielectric

Grease

Loading...

Loading...