5-18 LeeBoy Model 8510E Conveyor Paver

Maintenance

Electrical System

The electrical system is a 12-volt negative ground

system. Connect the positive (+) cable to the positive

(+) post of the battery. Connect the ground cable to

the negative (-) post of the battery. It is advisable to

disconnect the negative (-) cable rst and connect it last.

Reversed polarity can damage the electrical system.

Fire and Explosion Hazard! Always

observe battery polarity when connecting a battery

charger or jumper cables to the battery: negative (-)

to negative (-), positive (+) to positive (+). Failure to

do so can produce sparks.

When connecting a booster battery, connect one end

of the rst jumper cable to the positive (+) terminal of

the dead battery and the other end to the positive (+)

terminal of the booster battery. Connect one end of the

second jumper cable to the negative (-) terminal of the

booster battery and the other end to the frame of the

paver with the dead battery.

Fire and Explosion Hazard! Be sure

that the battery charger is in the OFF position before

connecting it to the battery.

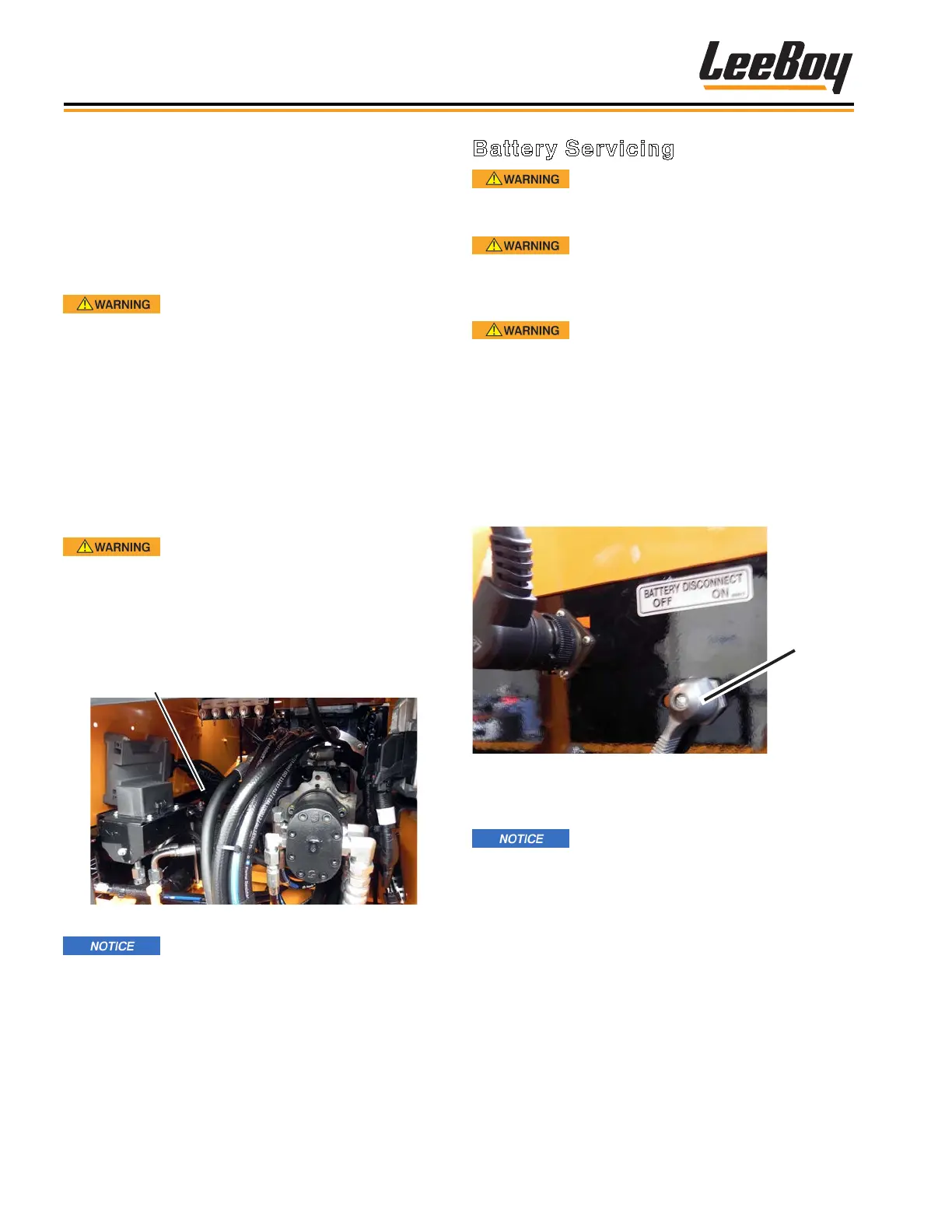

Be sure to keep the battery fully charged during cold

weather to keep it from freezing. Freezing weather has

little effect on a fully-charged battery. (Figure 5-21)

Figure 5-21. Battery Location

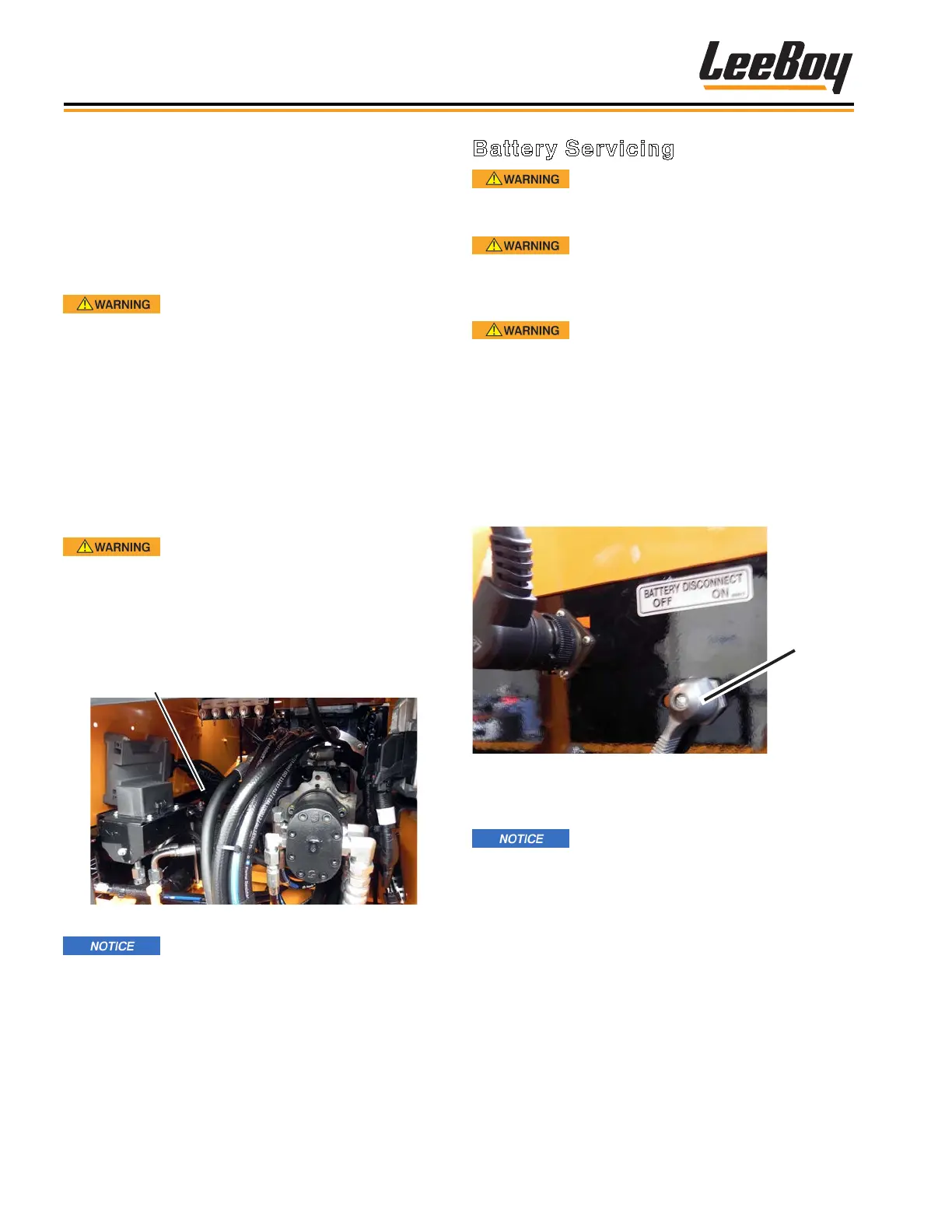

ALWAYS turn the master battery

switch off when working on the electrical system

or welding anywhere on the machine. Damage to

electrical components could result.

Battery Servicing

Batteries contain sulfuric acid.

ALWAYS wear safety goggles and protective clothing

when servicing the battery.

NEVER allow battery uid to come into

contact with clothing, skin or eyes. If battery uid

contacts the eyes or skin, immediately ush with

clean water and obtain prompt medical treatment.

Keep sparks and ames away from the

batteries as electrolyte gas is highly ammable.

1. Remove the rear access cover to access the

battery.

NOTE: When replacing the battery, discard the old

battery properly.

2. Before connecting the battery, turn off the master

switch, located under the operator control panel.

(Figure 5-22)

Battery

Disconnect

Switch

Figure 5-22. Battery Master Switch

3. Be certain that battery terminals and posts are clean

and that the battery cable terminals are tight.

Dirty or loose battery connections can

create high electrical resistance and permit arcing.

4. If corrosion is present around terminal connections,

remove and wash with ammonia or a solution of

1/4-pound (.11 kg) baking soda added to one quart

of warm water. Ensure the vent caps are tight to

prevent solution from entering the cells.

5. Pour clean water over the battery and surrounding

area to rinse away the solution.

6. Check vent cap breather openings to ensure they

are clear.

Loading...

Loading...