5-28 LeeBoy 8515E Conveyor Paver

Maintenance

ALWAYS be careful when working with

electrical components to avoid electrical shock. The

heat box is high voltage (220V), therefore, take extra

precautions to avoid electrical shock that could

cause serious injury or even death.

The control box consists of the major components

shown at Figure 5-30 on the previous page.

• The system timers, located on the control box cover.

• The element breakers are located in the lower surface

of the box.

• The other block in the center is used as a wire junction

block only.

NOTE: Control boxes are manufactured to t all

screed and paver combinations. If not all

plugs are connected to wires, it may be

normal. Be sure to keep unused plugs

covered with mating protective caps.

• Each element output consists of two wires--one

connects to the L-1 circuit and the other to the L-2

circuit.

• Each breaker has two terminals--one is connected

to the main input and the other terminal to an element

output wire.

• The L-1 circuit is the left bank of element breakers.

• The L-2 circuit is the right bank of element breakers.

Heating element relays “make” or “break” the circuit

to each element to start or stop the heating cycles.

When the HEAT ON button is depressed, 12VDC is

momentarily applied to the main timer relay to start the

timing cycle.

Element Resistance TestingElement Resistance Testing

The breakers are wired into each leg of each element.

If an element has a fault, either in the wiring, or in the

element itself, the breaker will trip and power will no

longer be applied to that leg of the element.

When a breaker in the control box has “tripped,” there

may be a problem in the wiring or an element in the

circuit.

The breakers can be manually reset by depressing the

trip button back into place when they are extended. If

the breaker still does not reset, you need to test or

possibly replace an element.

If the element is functioning correctly, you should read

a resistance between the connector pins when testing.

A faulty element will show high resistance, indicating a

bad element. Refer to the following resistance table and

element testing procedure:

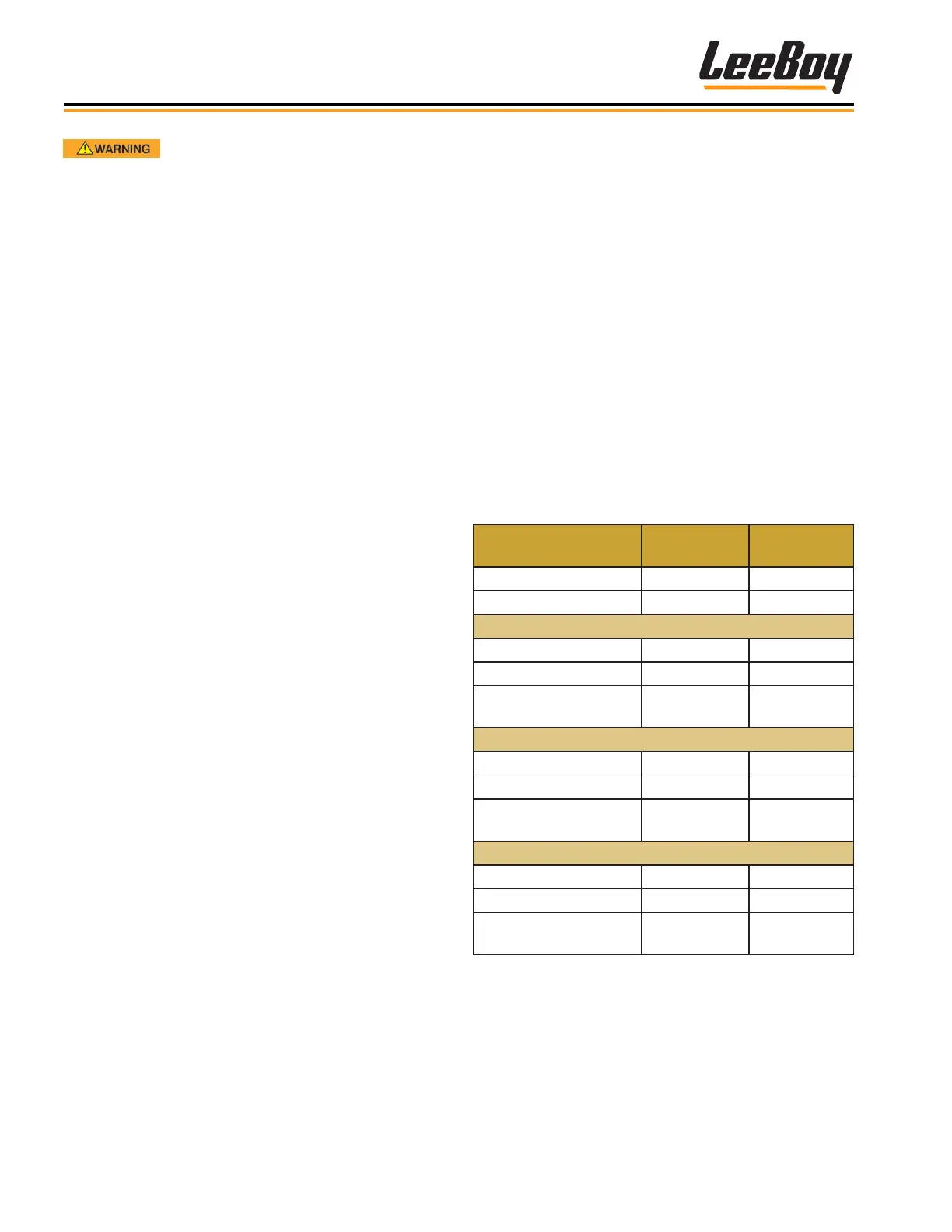

Table 5-7. Element Resistance Table

Item

STD Legend

Screed

HD815

Screed **

Generator Size (kW) 10 kW 10 kW

Breaker Size 50 Amp 50 Amp

Main Screed Elements (2)

Wattage Per Element 1750 W 2000 W

Total Wattage 3500 W 4000 W

Resistance per

Element

24.3 - 26.8 Ω 26 - 32 Ω

Screed Extension Elements (2)

Wattage Per Element 1000 W 1000 W

Total Wattage 2000 W 2000 W

Resistance per

Element

42.5 - 46.8 Ω 62.6 - 32 Ω

Heated Endgate Elements (2) **

Wattage Per Element N/A 500 W

Total Wattage N/A 1000 W

Resistance per

Element

N/A 88.5 - 108 Ω

** Option item.

Loading...

Loading...