7. WEB Control Application

7-26

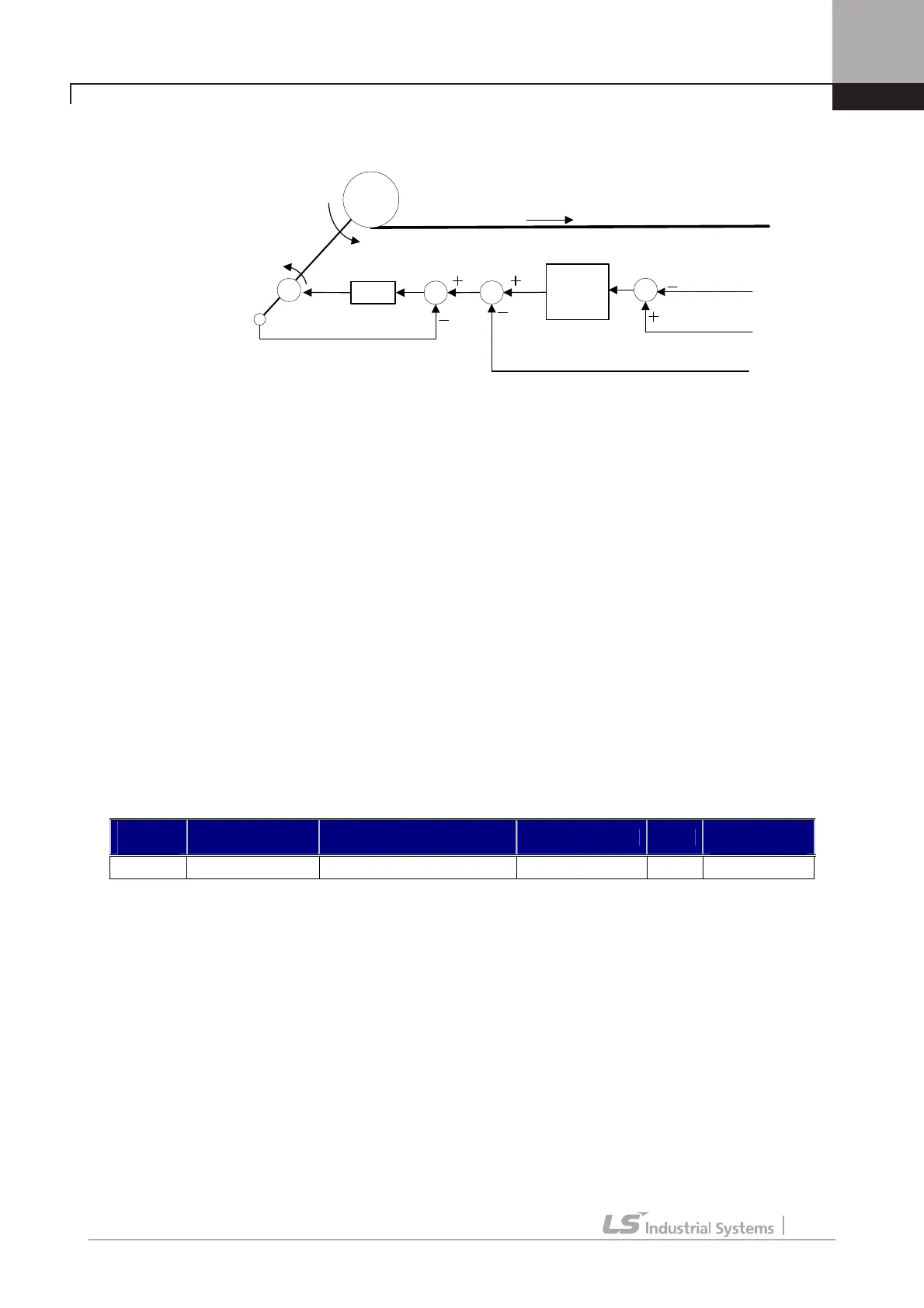

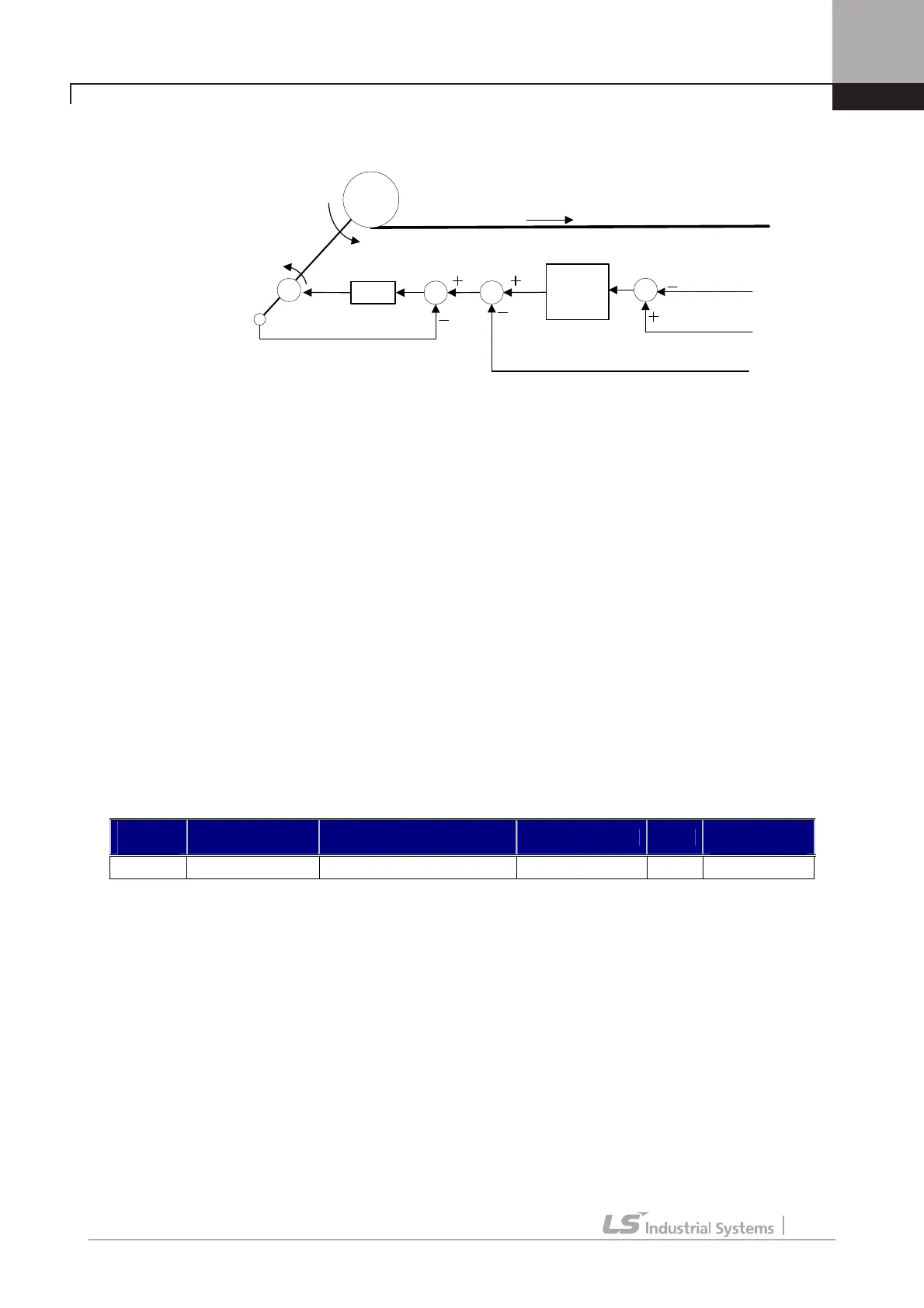

Unwind/Underwind Setting, Roll Rotating Direction in case of Forward Direction Operation

7.7.7 Tension controlling setting

1) WEB_19 Tension Input : tension Reference Input Setting

In case of using loadcell in the tension control you have to set tension reference. If using dancer, you have to set

the position reference of dancer. In this case, Taper, Stall and Boost are required according to the system

requirement. This function code is the function code where tension reference is set when using the loadcell as the

tension control-use sensor. Tension reference is input with the sum of the analog input value at the time of setting

WEB_19 Tension Input and analog input (Ai1 ~ Ai3 Define) to “Tension Ref” and the set value of Address 0x0511 in

common area. For further detail, please refer to Block Diagram at the time of Web Control. In case of using dancer,

this function code plays the role giving the dancer Taper function. In case of setting the set value of WEB_28

PIDRef Sel to “Dancer Pos”, and setting WEB_29 Dancer Pos, WEB_19 Tension Input can be set with the input

tension of the dancer. At this time, you may connect with the dancer after setting one of analog output (AIO_74

AO1 Define, AIO_79 AO2 Define) to “Tension Out”.

Function

Code

Loader Display Name of Function Set Range Unit

Factory

Default

WEB_19 Tension Input Tension Reference Input -100.0 ~ 100.0 % 0.0

2) WEB_20 Taper Type : Taper Type Setting

3) WEB_21 Taper Input : Taper Amount Input

In case of Winder, as the diameter gets larger, the tension toward the center direction of the diameter increases.

Desired tension is, as shown in the Figure 12, toward the direction of dot line. The tension occurs from the stress,

however, and therefore the sum of two vectors work as the total tension. To maintain the tension toward the

desired direction, you may use this taper function. There are three methods of using taper function. First; it is not

to use taper function, that is tape function is not applicable in case of powering On after setting WEB_20 to “None”,

setting WEB_20 to the others than “None” but setting WEB_21 Taper Input to 0.0[%], and setting one of multi-

function inputs (DIO_01 ~ DIO_07) to “Taper Disable”. Second; it is to set to “Hyperbolic” when the tension

Motor

Unwind(Under wind) with Forward Run command

Line Direction

Reverse

direction

PID output

X

Line Speed

command

X

Speed

Feedback

ASR

Motor

Speed

making

X

Splicing %

Unwin

der

Loading...

Loading...