7. WEB Control Application

7-16

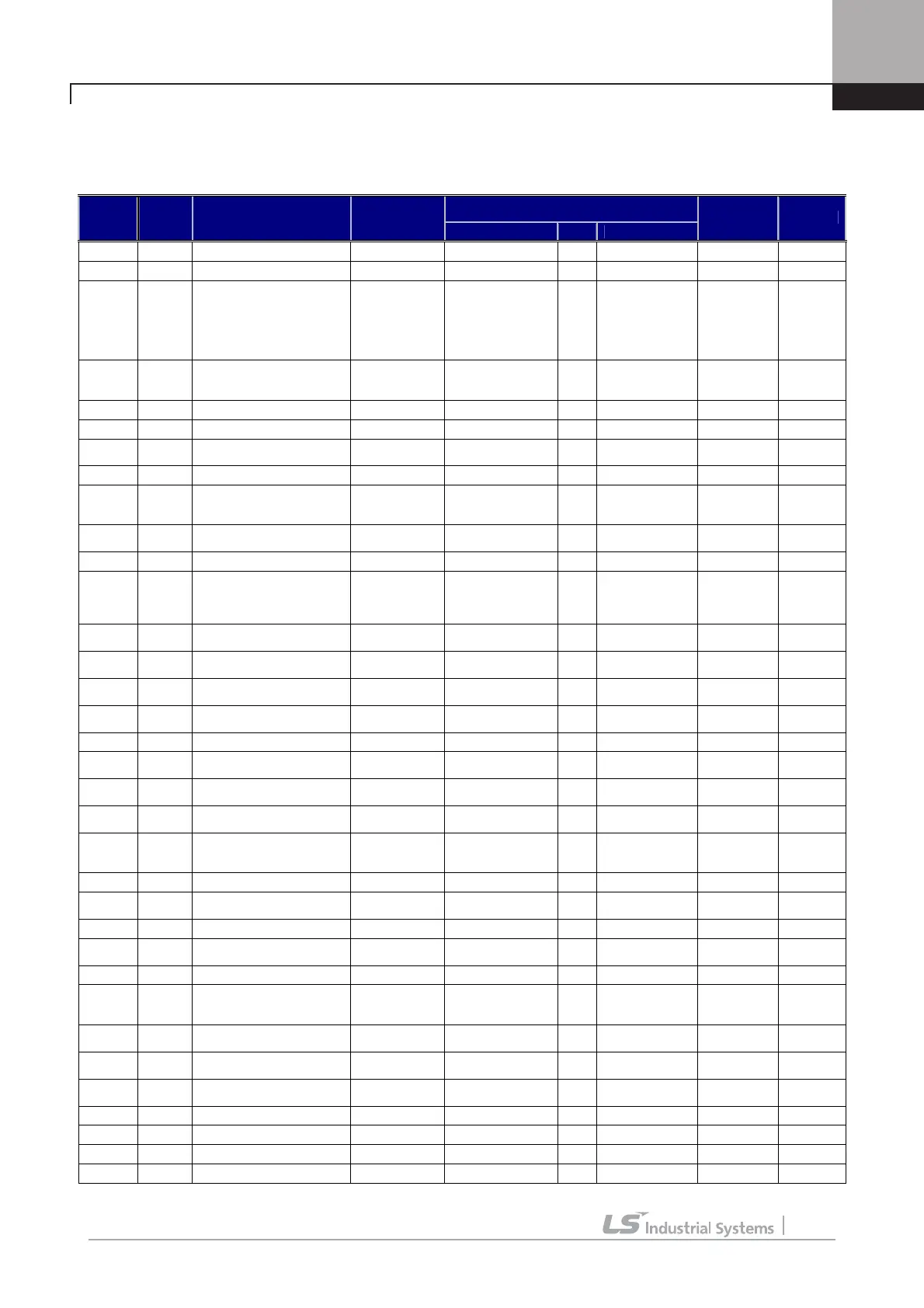

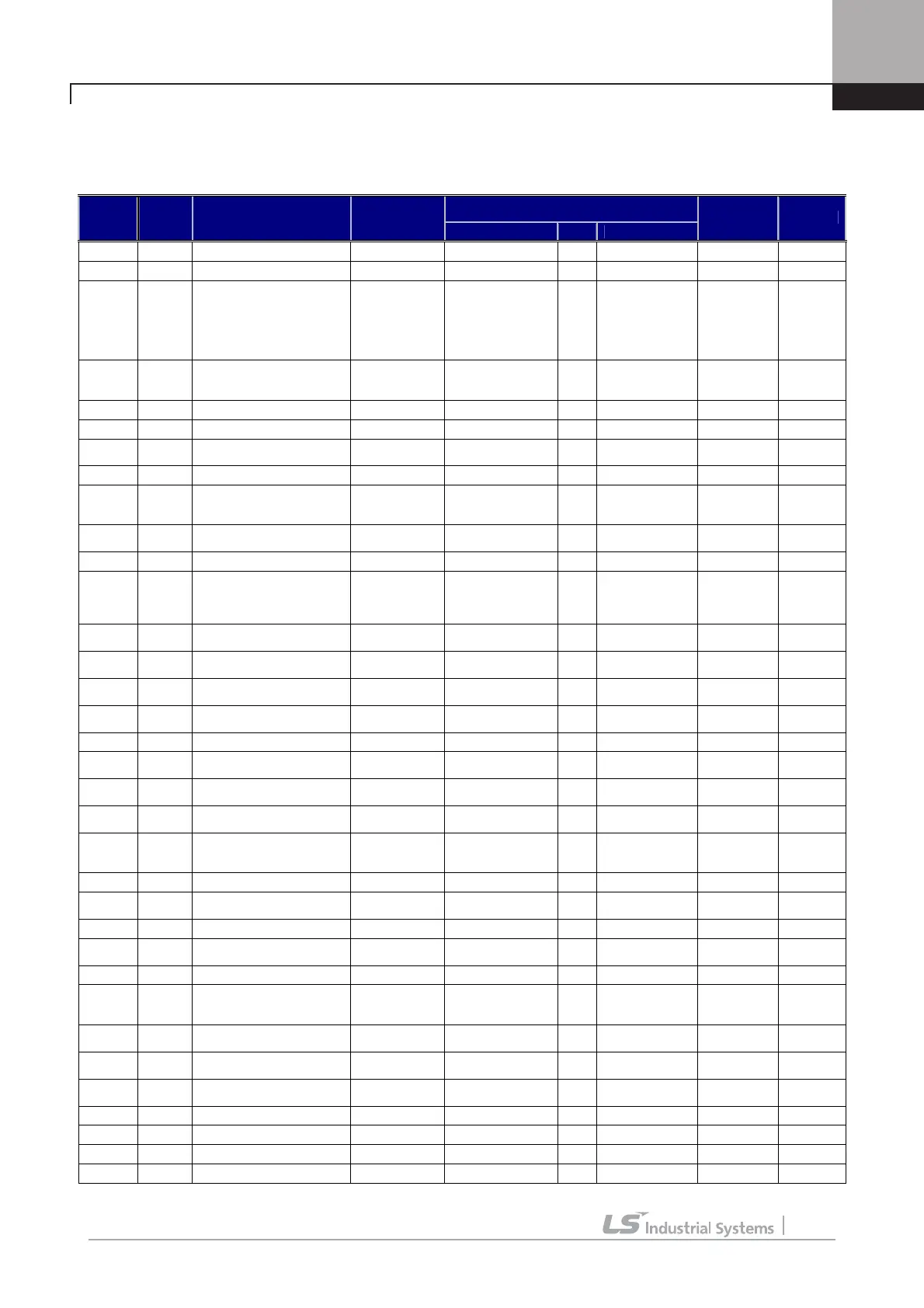

7.6 Function Code of WEB Application Group (WEB_[][])

Setting Data

Code

No.

Comm.

Addr

Code Name LCD DISPLAY

Range Unit Default

Adjustment

During Run

PAGE

WEB_00 - Selection of Function Code Jump Code 1 ~ 59 Yes

WEB_01 7C01 Diameter Size Display Diameter 5.0 ~ 100.0 % 10.0 No 7-18

WEB_02 7C02 Selected Initial Diameter

Current Core

(Display Only)

0 (Diam Preset 1)

1 (Diam Preset 2)

2 (Diam Preset 3)

3 (Diam Preset 4)

4 (Analog)

5 (Option)

0 (Diam Preset 1) No 7-18

WEB_03 7C03

Setting of the Type of

Diameter Initialization

DiaPresetSrc

0 (Keypad)

1 (Analog)

2 (Option)

0 (Keypad) No 7-18

WEB_04 7C04 1

st

Diameter Initial Value Diam Preset 1 WEB_10 ~ 100.0 % 10.0 No 7-20

WEB_05 7C05 2nd Diameter Initial Value Diam Preset 2 WEB_10 ~ 100.0 % 15.0 No 7-20

WEB_06 7C06 3rd Diameter Initial Value Diam Preset 3 WEB_10 ~ 100.0 % 20.0 No 7-20

WEB_07 7C07 4th Diameter Initial Value Diam Preset 4 WEB_10 ~ 100.0 % 25.0 No 7-20

WEB_08 7C08

Motor Maximum Rotating

Speed with Min. Diameter

MaxMotor SPD 75.0 ~ 3600.0 rpm 300.0 Yes 7-21

WEB_09 7C09

Minimum Effective Line

Speed

MinLine SPD 0.0 ~ 100.0 % 5.0 No 7-21

WEB_10 7C0A Minimum Diameter Min Diameter 5.0 ~ 100.0 % 10.0 No 7-22

WEB_11 7C0B

Selection of

Acceleration/Deceleration

Time Setting in case of WEB

Control

AccDecWeb 0 (No) / 1 (Yes) 1 (Yes) No 7-22

WEB_12 7C0C

Acceleration Time in case of

WEB Control

Acc TimeWeb 0.00 ~ 6000.0 sec 0.50 Yes 7-22

WEB_13 7C0D

deceleration Time in case of

WEB Control

Dec TimeWeb 0.00 ~ 6000.0 sec 0.50 Yes 7-22

WEB_14 7C0E

Setting of the Type of

Diameter Computation

Diameter Src

0 (Internal)

1 (Exernal)

0 (Internal) No 7-22

WEB_15 7C0F

Time Constant of Diameter

Computation LPF

Diameter LPF 0.01 ~ 300.00 sec 5.00 Yes 7-23

WEB_16 7C10 False Core Value False Core 0.0 ~ 50.0 % 5.0 Yes 7-23

WEB_17 7C11 Rewind/Unwind Setting Re/Un Wind

0 (Rewind)

1 (Unwind)

0 (Rewind) No 7-23

WEB_18 7C12

Overwind /Underwind

Setting

O/U Wind

0 (Overwind)

1 (Underwind)

0 (Overwind) No 7-24

WEB_19 7C13

Tension Reference Input

Setting

TensionInput -100.0 ~ 100.0 % 0.0 Yes 7-26

WEB_20 7C14 Taper Type Setting Taper Type

0 (None)

1 (Hyperbolic)

2 (Linear)

0 (None) No 7-26

WEB_21 7C15 Taper Input Value Setting Taper Input -100.0 ~ 100.0 % 0.0 No 7-26

WEB_22 7C16 Boost Type Setting Boost Type

0 (Proportional)

1 (Fixed)

0 (Proportional) No 7-27

WEB_23 7C17 Boost Input Value Setting Boost Input 0.0 ~ 50.0 % 0.0 No 7-27

WEB_24 7C18 Stall Type Setting Stall Type

0 (Proportional)

1 (Fixed)

0 (Proportional) No 7-28

WEB_25 7C19 Stall Input Value Setting Stall Input 0.0 ~ 50.0 % 0.0 No 7-28

WEB_26 7C1A

Ramp Time Setting of

Tension Reference Input

Value

Tension Ramp 0.00 ~ 600.00 sec 5.00 Yes 7-29

WEB_27 7C1B

Tension Control Enable

Setting

Tension Enb

0 (Disable)

1 (Enable)

1 (Enable) No 7-30

WEB_28 7C1C PID Reference Type Setting PIDRef Sel

0 (Dancer Pos)

1 (Taper Out)

1 (Taper Out) No 7-30

WEB_29 7C1D

Dancer Reference position

Setting

Dancer Pos -100.0 ~ 100.0 % 0.0 Yes 7-31

WEB_30 7C1E Process PID P1 Gain Setting ProcPID Kp1 0.0 ~ 999.9 % 10.0 Yes 7-31

WEB_31 7C1F Process PID P2 Gain Setting ProcPID Kp2 0.0 ~ 999.9 % 0.0 Yes 7-31

WEB_32 7C20 Process PID I1 Gain Setting ProcPID Ki1 0.0 ~ 100.0 sec 5.0 Yes 7-31

WEB_33 7C21 Process PID I2 Gain Setting ProcPID Ki2 0.0 ~ 100.0 sec 0.0 Yes 7-31

Loading...

Loading...