13 Calibration of Conveyer and Robot Coordinate Systems (

“

A1

”

program)

6) Press the [FUNCTION] key, and change the function display

7) Press the [F1] (FWD) key and execute step feed. "(1)Encoder No ......." is displayed

8) Work according to the comment directions in the robot program.

9) Next "' (2) On conveyor both .. Execute step feed to ".

10) Repeat (7) - (8) and execute step feed to "End."

11) Press the [F2] (JUMP) key and input the step number. Press the [EXE] key. Then returns to first step

12) Press the [FUNCTION] key, and change the function display. Press the [F4] (close) key and close the

program.

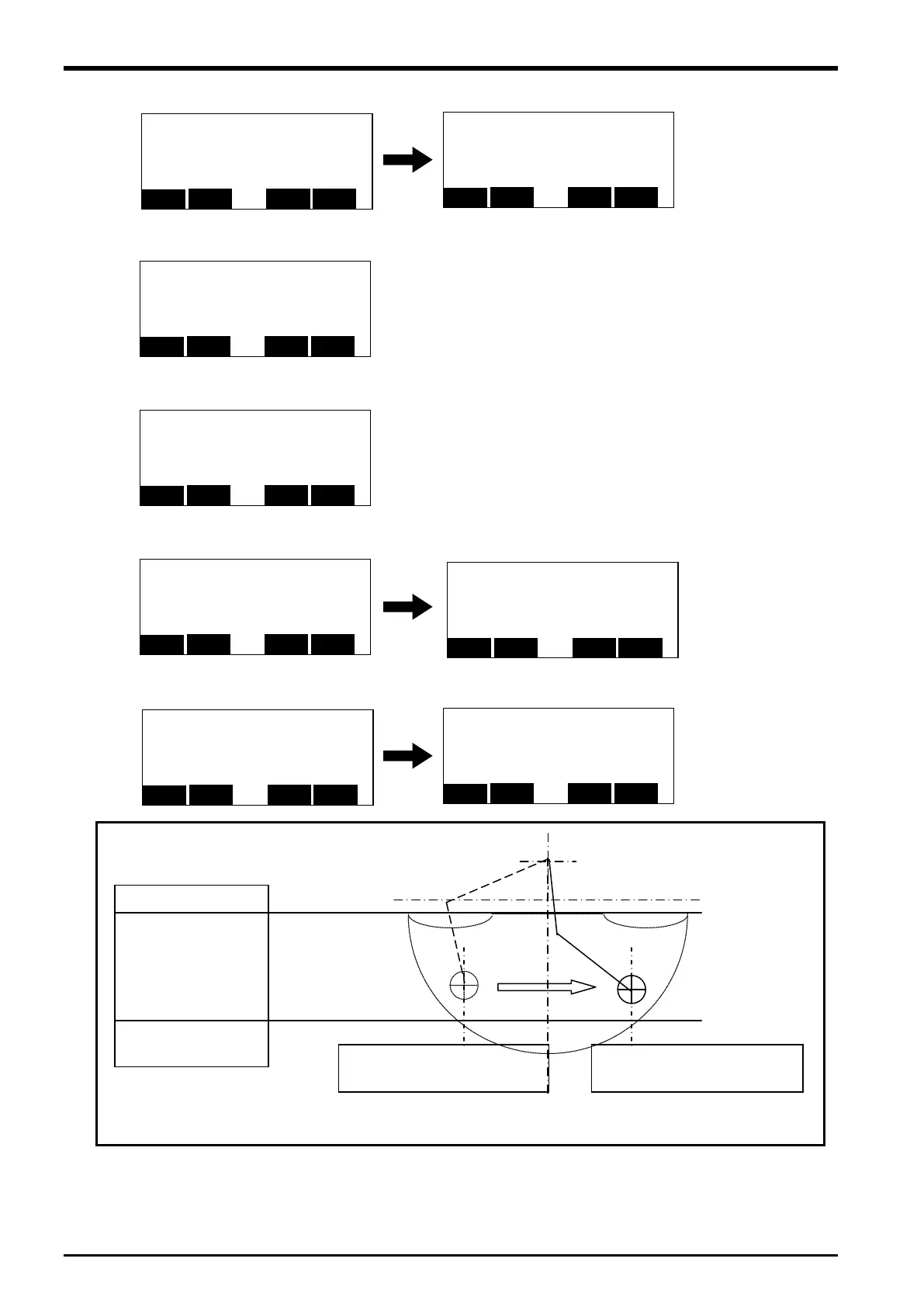

Figure 13

−1 Conveyer and Robot Calibration Operation Diagram

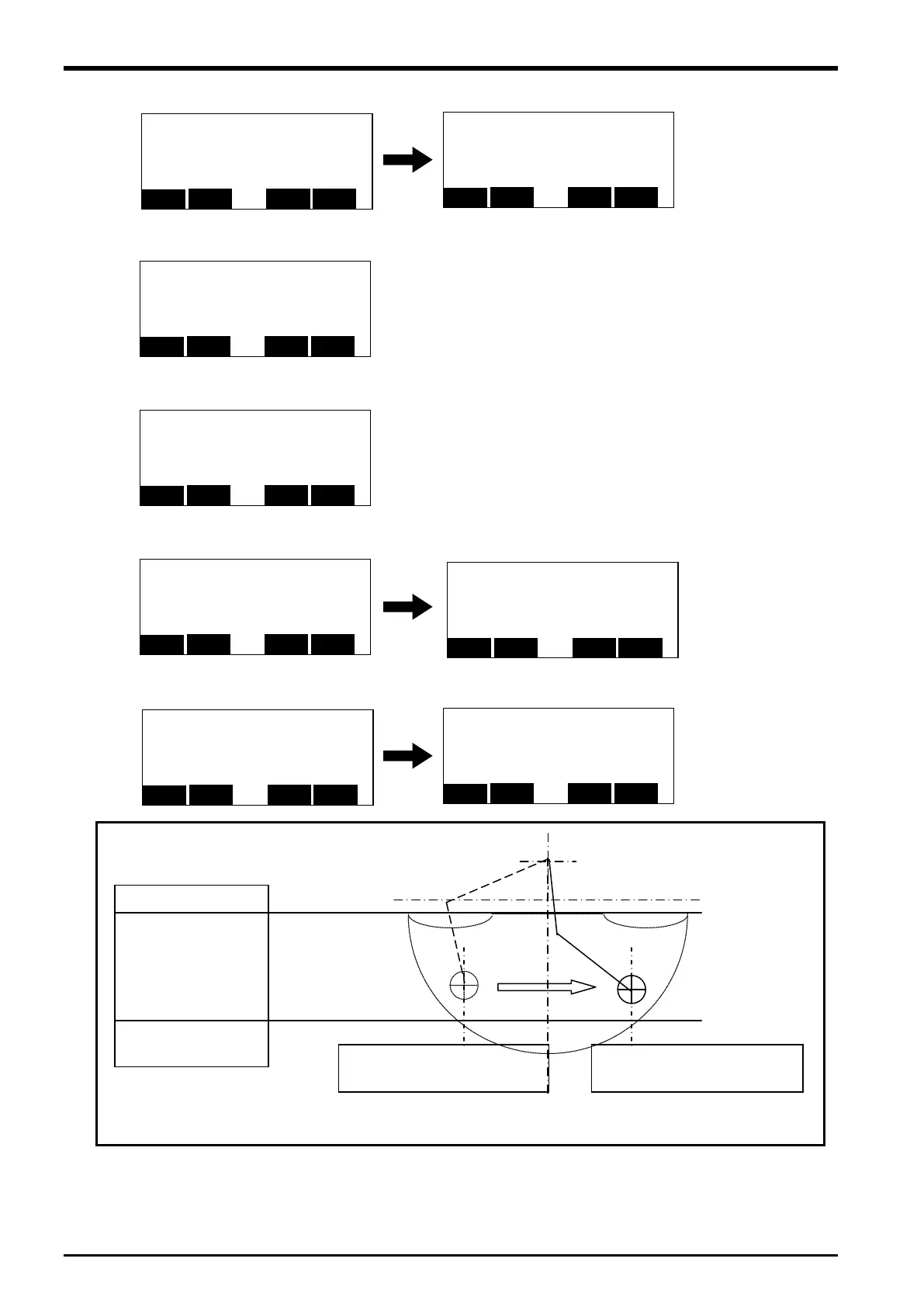

2 '# tracking robot‐conveyor calibra

4 '# Create/version : 2006.04.21 A1

1 '## Ver.A1 ########################

2 '# tracking robot‐conveyor calibra

4 '# Create/version : 2006.04.21 A1

1 '## Ver.A1 ########################

2 '# tracking robot‐conveyor calibra

4 '# Create/version : 2006.04.21 A1

1 '## Ver.A1 ########################

10 If PE.X<1 Or PE.X>MECMAX Then Er

12 '(2)On conveyor both ....

5 '# COPYRIGHT : MITSUBISHI ELECTRIC

6 '##################################

4 '# Create/version : 2006.04.21 A1

2 '# tracking robot‐conveyor calibra

4 '# Create/version : 2006.04.21 A1

1 '## Ver.A1 ########################

2 '# tracking robot‐conveyor calibra

4 '# Create/version : 2006.04.21 A1

1 '## Ver.A1 ########################

Encoder data acquisition

Position acquisition

a workpiece sensor

Encoder data acquisition

Position acquisition

* (1) - (6) in the figure shows the details of operations in the sample program.

13-50 Operation procedure

Loading...

Loading...