16 Teaching and Setting of Adjustment Variables (

“

1

”

Program)

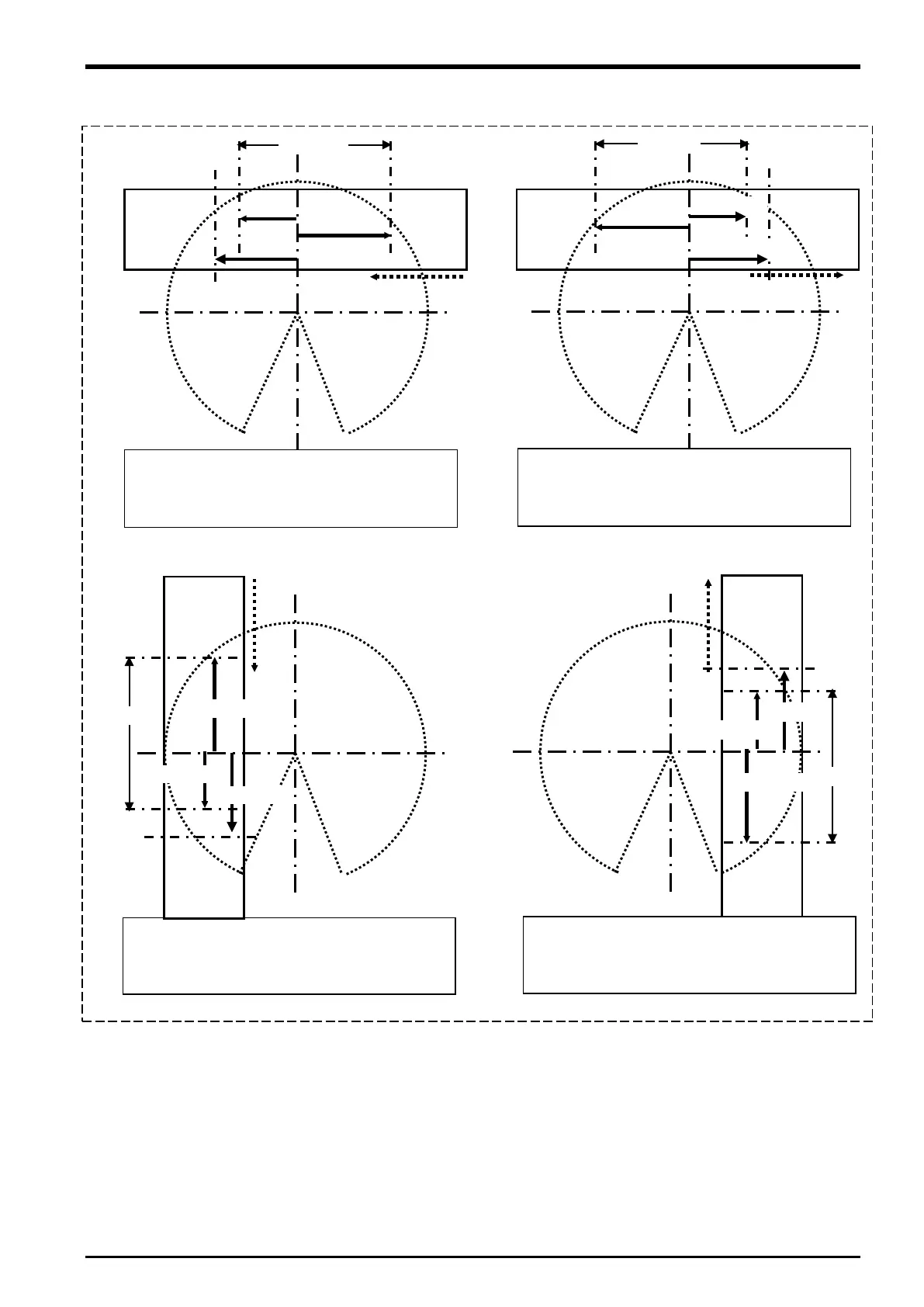

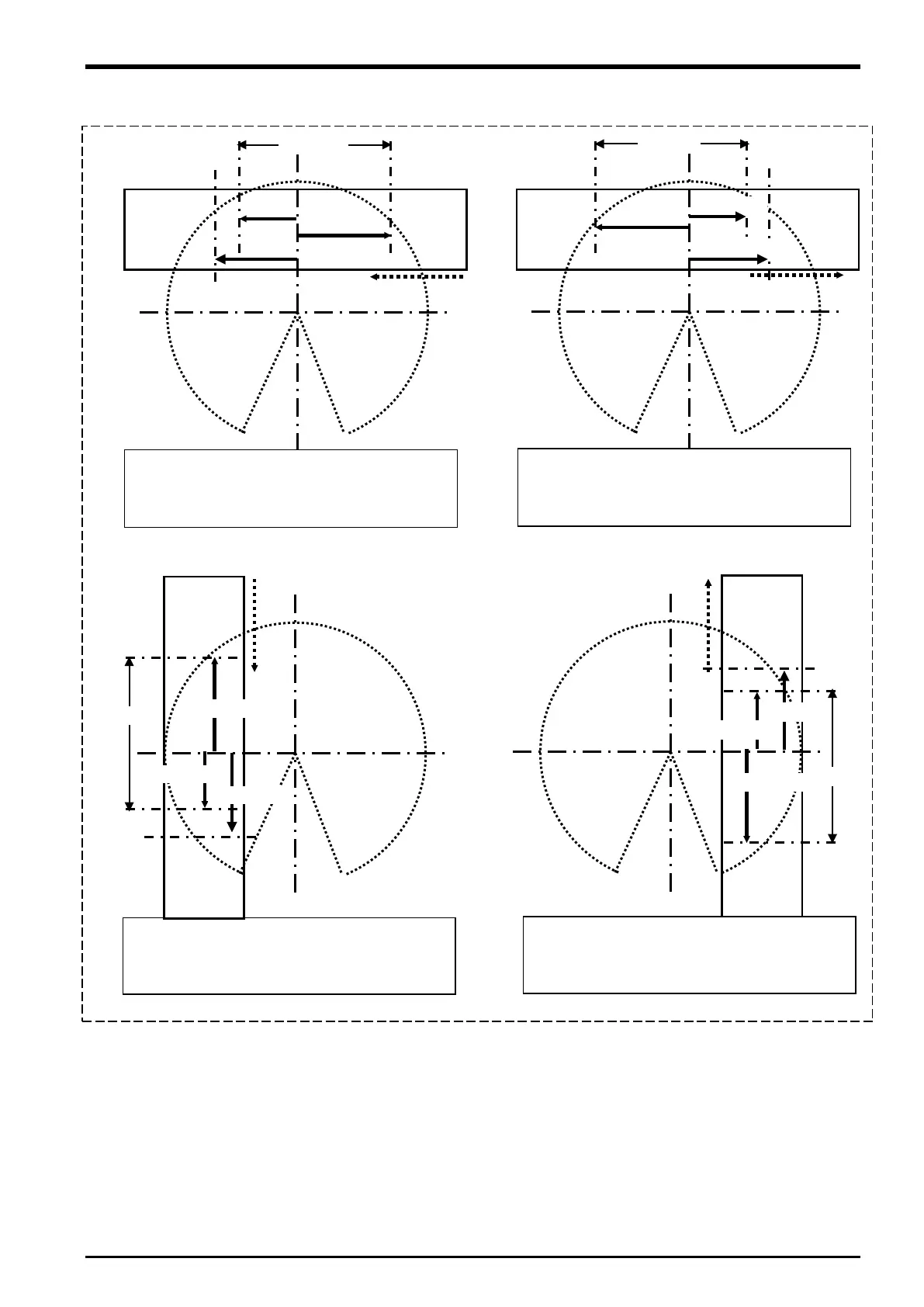

Figure 16

−3 Diagram of Relationship between Adjustment Variables “PRNG” and “PTN” in the Program

When the conveyer is placed in front of the

robot

and the workpiece moves from the

(= the X coordinate of PTN is “1”)

,Z)=(+500,+300,+400)

Workpiece

movement direction

When the conveyer is placed on the left side

of the robot and the workpiece move

the front to rear (= the X coordinate of PTN is

Workpiece

movement direction

When the conveyer is placed on the right side

of the robot and the workpiece move

the rear to front (= the X coordinate of PTN is

Workpiece

movement direction

When the conveyer is placed in front of the

robot and the workpiece moves from the lef

to right (= the X coordinate of PTN is “2”)

PRNG: (X,Y,Z)=(+300,+100,+200)

Workpiece

movement direction

Setting of adjustment variables in the program 16-83

Loading...

Loading...