199

Pulse Outputs Section 5-2

Perform origin search

and origin return opera-

tions.

Origin functions (Origin search and

origin return)

Origin search and origin return operations can be exe-

cuted through pulse outputs.

• Origin search:

To start the origin search, set the PLC Setup to

enable the origin search operation, set the various

origin search parameters, and execute the ORIGIN

SEARCH instruction (ORG(889)). The Unit will deter-

mine the location of the origin based on the Origin

Proximity Input Signal and Origin Input Signal. The

coordinates of the pulse output's PV will automatically

be set as the absolute coordinates.

• Origin return:

To return to the predetermined origin, set the various

origin return parameters and execute the ORIGIN

SEARCH instruction (ORG(889)).

Change the target posi-

tion during positioning.

(For example, perform

an emergency avoid

operation with the Multi-

ple Start feature.)

Positioning with the PLS2(887)

instruction

When a positioning operation started with the PULSE

OUTPUT (PLS2(887)) instruction is in progress, another

PLS2(887) instruction can be executed to change the

target position, target speed, acceleration rate, and

deceleration rate.

Change speed in steps

(polyline approxima-

tion) during speed con-

trol.

Use the ACC(888) instruction (con-

tinuous) to change the acceleration

rate or deceleration rate.

When a speed control operation started with the

ACC(888) instruction (continuous) is in progress,

another ACC(888) instruction (continuous) can be exe-

cuted to change the acceleration rate or deceleration

rate.

Change speed in steps

(polyline approxima-

tion) during positioning.

Use the ACC(888) instruction (inde-

pendent) or PLS2(887) to change the

acceleration rate or deceleration rate.

When a positioning operation started with the ACC(888)

instruction (independent) or PLS2(887) instruction is in

progress, another ACC(888) (independent) or

PLS2(887) instruction can be executed to change the

acceleration rate or deceleration rate.

Perform fixed distance

feed interrupt.

Execute positioning with the

PLS2(887) instruction during an

operation started with SPED(885)

(continuous) or ACC(888) (continu-

ous).

When a speed control operation started with the

SPED(885) instruction (continuous) or ACC(888)

instruction (continuous) is in progress, the PLS2(887)

instruction can be executed to switch to positioning, out-

put a fixed number of pulses, and stop.

After determining the

origin, perform position-

ing simply in absolute

coordinates without

regard to the direction

of the current position

or target position.

The positioning direction is selected

automatically in the absolute coordi-

nate system.

When operating in absolute coordinates (with the origin

determined or INI(880) instruction executed to change

the PV), the CW or CCW direction is selected automati-

cally based on the relationship between the pulse output

PV and the pulse Output Amount specified when the

pulse output instruction is executed.

Perform triangular con-

trol.

Positioning with the ACC(888)

instruction (independent) or

PLS2(887) instruction.

When a positioning operation started with the ACC(888)

instruction (independent) or PLS2(887) instruction is in

progress, triangular control (trapezoidal control without

the constant-speed plateau) will be performed if the

number of output pulses required for acceleration/decel-

eration exceeds the specified target pulse Output

Amount.

(The number of pulses required for acceleration/deceler-

ation equals the time required to reach the target fre-

quency x the target frequency.)

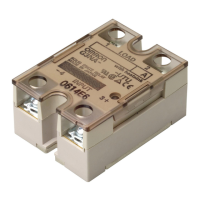

Use variable duty factor

outputs for time-propor-

tional temperature con-

trol.

Control with analog inputs and the

variable duty factor pulse output func-

tion (PWM(891)).

Two built-in outputs can be used as PWM(891) outputs 0

and 1 by executing the PWM(891) instruction.

Purpose Function Description

Loading...

Loading...