327

Inverter Positioning Section 5-3

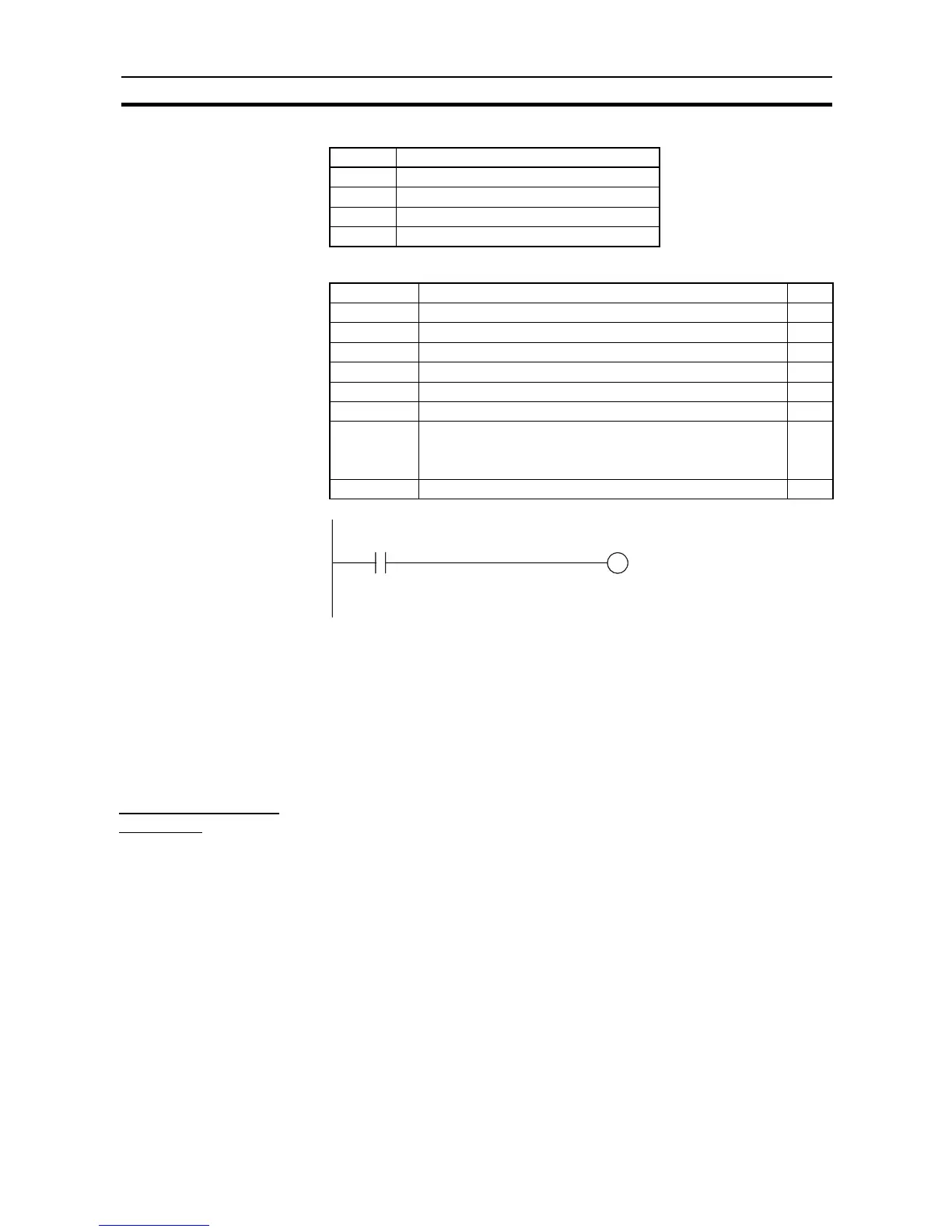

■ Internal Work Addresses

■ Settings Addresses

Modbus Communications

Add the above instructions to the end of the program as a starting condition

for the ladder programming example. For error processing, refer to the ladder

program in

6-3-3 Modbus-RTU Easy Master Function

and to the inverter’s

manual.

5-3-12 Application Example with an Analog Output

Positioning with

Trapezoidal Control

Specifications and

Operation

When start input CIO 1.04 turns ON, 600,000 pulses are output internally for

inverter positioning 0 to turn the motor shaft.

Note Refer to

5-3-7 Determining the Internal Pulse Output Frequency

for the for-

mula to convert the frequency and use the converted internal pulse frequency.

The number of output pulses is calculated from the encoder specifications

and the high-speed counter multiplier.

Address Usage

D1 Bits 00 to 03: Run/Stop Command

D2 Bits 00 to 15: Frequency Command Value

D10 Bits 00 to 03: Forward/Reverse Command

D15 Bit 09: Forward/Reverse Command

Address Usage Data

D32200 Bits 00 to 07: Slave address 01

D32201 Bits 00 to 07: Function code 10

D32202 Bits 00 to 07: Number of communications data bytes 09

D32203 Bits 00 to 15: Register number of write start data 0001

D32204 Bits 00 to 15: Number of data registers to write 0002

D32205 Bits 08 to 15: Number of attached data bytes 04

D32206 Bits 00 to 07: Upper bytes of frequency command value in D2

Bit 08: Run/Stop Command

Bit 09: Forward/Reverse Command

---

D32207 Bits 08 to 15: Lower bytes of frequency command value in D2 ---

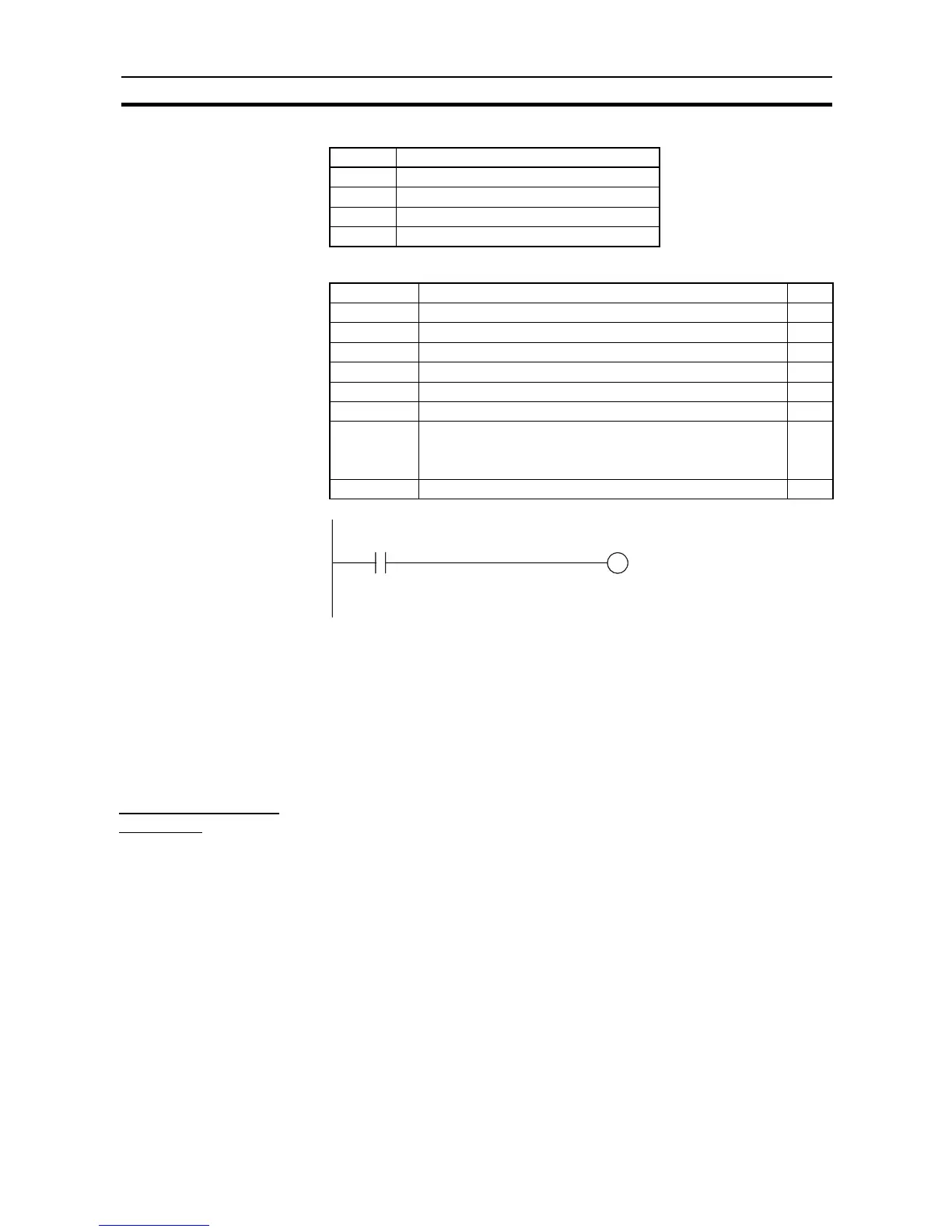

A26.00

Operation

Command Flag

A641.00

Modbus-RTU Master Execution Bit

Loading...

Loading...