282

Inverter Positioning Section 5-3

Inverter Positioning with the CP1L

With the CP1L’s inverter positioning function, feedback is constantly read for

the positioning data while controlling the position.

Note (1) The CP1L’s inverter positioning function is designed to increase position-

ing speed and stopping precision by reading position information and us-

ing a feedback loop with an error counter to switch speeds. It does not

increase the response, stopping precision, or speed change rate of the

inverter and motor. These are characteristics of the inverter and motor.

Refer to user documentation on your inverter and motor for details.

(2) The corresponding pulse output number (0 or 1) cannot be used for the

PULSE WITH VARIABLE DUTY FACTOR instruction (PWM) if inverter

positioning 0 or 1 is used. The high-speed counter of the same number

(0 or 1) is used to input the feedback pulse.

CP1L

Position feedback

Speed command

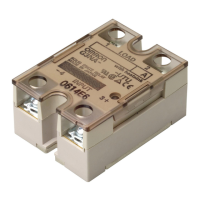

Inverter

Power

supply

frequency

Inductive motor

Encoder

Feedback pulses

There is no positioning error because the present position and position error

are constantly monitored and corrected.

Frequency

Low-speed operation is not required to prevent

positioning error. Control is simplified because the

low-speed position does not need to be calculated.

Time

Time

Position

Actual/Settings

Command output

Settings/Actual

Positioning is faster because low-speed

operation is not used.

Loading...

Loading...