8

Features and Main Functions Section 1-1

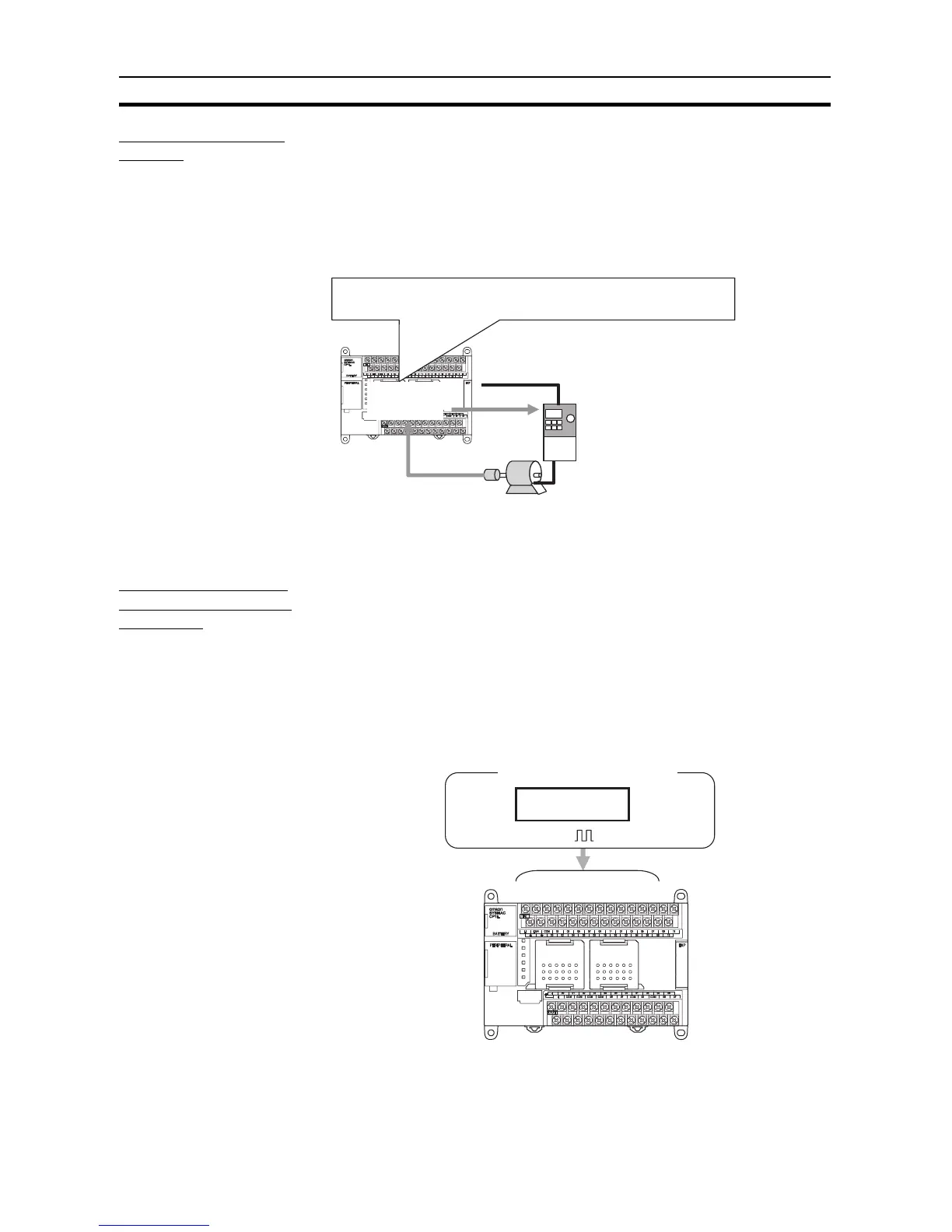

Positioning with an

Inverter

Positioning can be controlled using an inverter. Previously, an internal pulse

output with trapezoidal acceleration/deceleration is created using the PULSE

OUTPUT instruction. The position offset is calculated using an error counter

for the feedback pulse input from a rotary encoder connected to an inductive

motor and the internal pulse output. The error counter is then used to output a

speed command to the inverter to control positioning. This enables positioning

with high-capacity motors, as well as low-cost positioning with small-capacity

motors (in comparison to using a servo).

Note If high-precision positioning is required, we recommend using an inverter with

vector control.

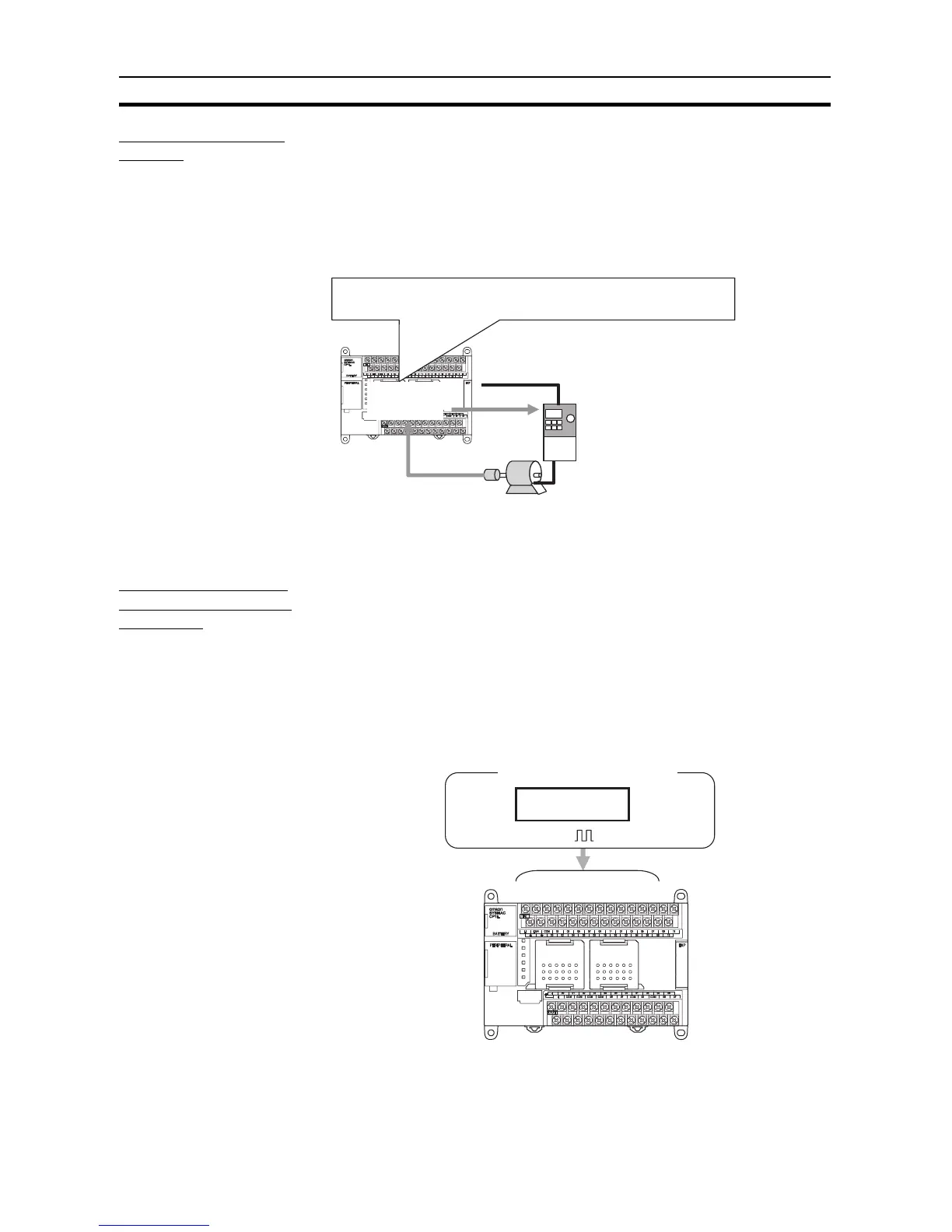

Full Complement of

High-speed Counter

Functions

High-speed counter inputs can be enabled by connecting rotary encoders to

the built-in inputs. The ample number of high-speed counter inputs makes it

possible to control a multi-axis device with a single PLC.

• Four 100-kHz (single phase)/50-kHz (differential phases) high-speed

counter inputs (4 counters/2 axes) are provided as a standard feature.

(See note.)

• For CP1L-J PLCs, four 20-kHz (single phase)/10-kHz (differential phases)

high-speed counter inputs (4 counters/2 axes) are provided as a standard

feature. (See note.)

Note Settings in the PLC Setup determine whether each input point is to

be used as a normal input, interrupt input, quick-response input, or

high-speed counter.

A virtual pulse output is created using a pulse output instruction, the position

offset is calculated using an error counter, and a frequency (i.e., speed)

command is output according to the position offset to control positioning.

Analog output or RS-422A (Modbus-RTU)

Frequency

command

Pulse input

Encoder

Pulse Output

Instruction

Inverter

Motor

24 built-in inputs

(Functions can be assigned.)

High-speed counters

(4 counters/2 axes)

100 kHz (single phase)

Loading...

Loading...