Multi-function Compact Inverter 3G3MX2-EV2 User’s Manual (I666-E1)

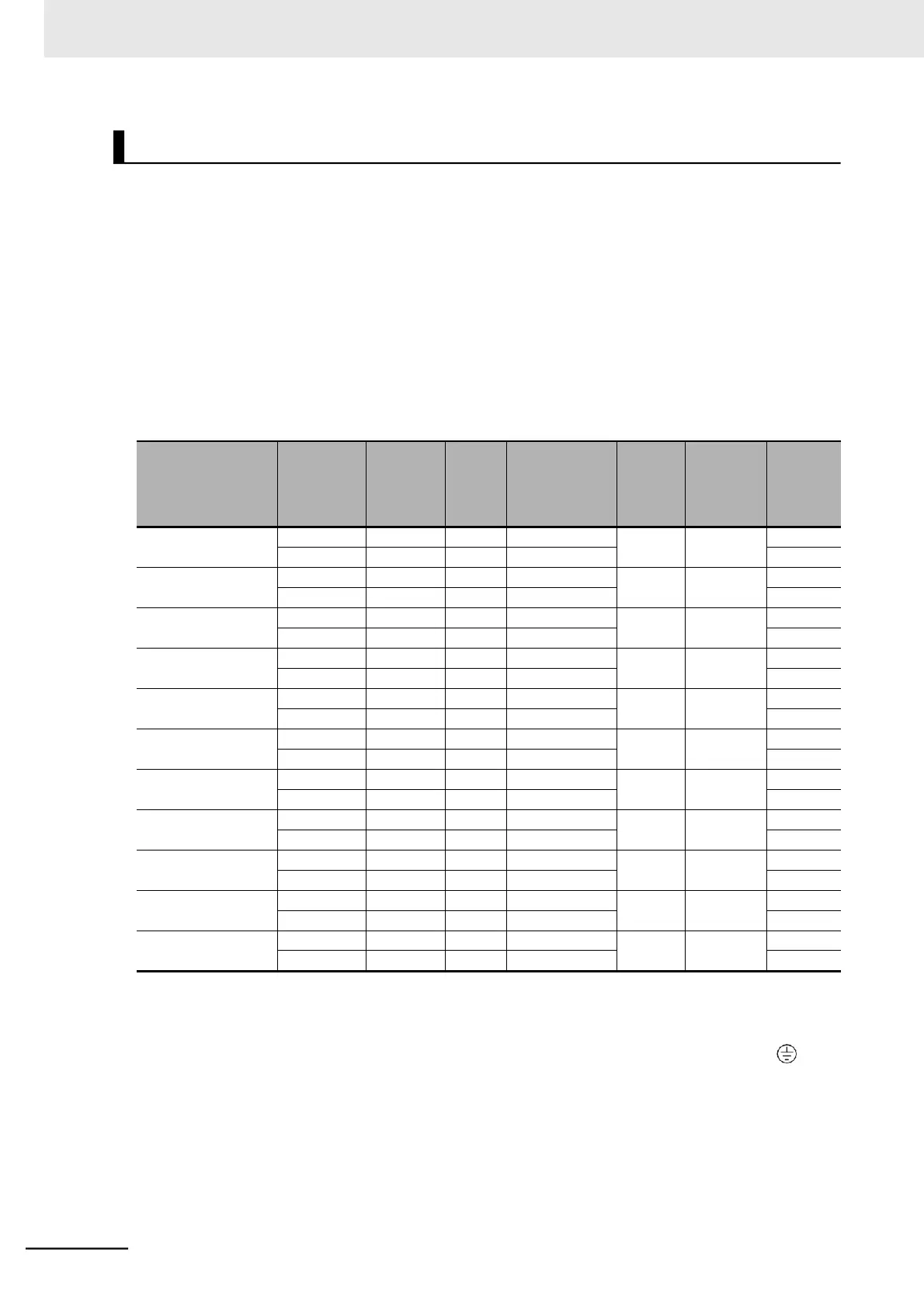

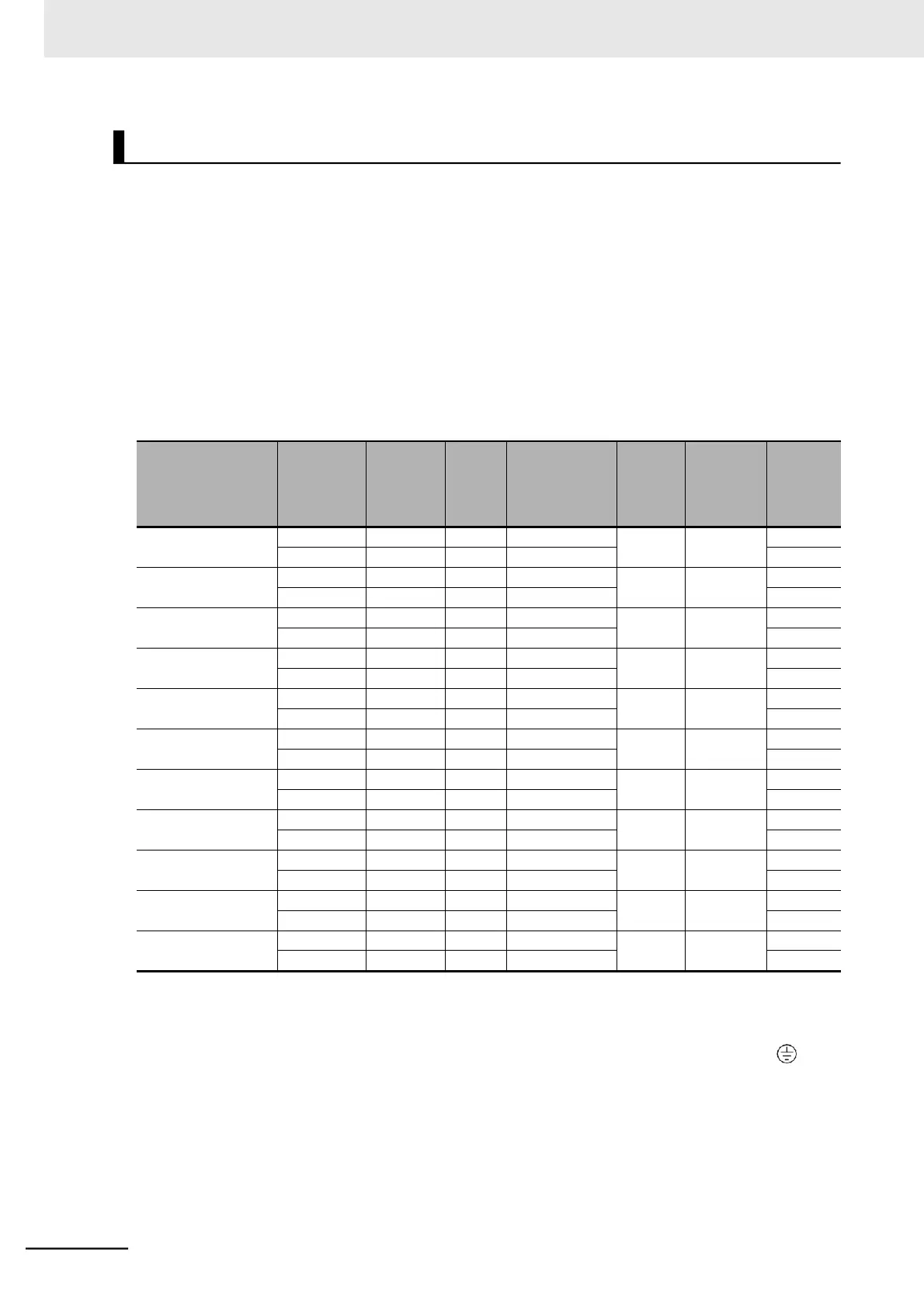

For inverter wiring, crimp terminal, and terminal screw tightening torque, refer to the table below.

•

Each table shows an example of connecting the standard 3-phase motor with four poles to an

inverter.

•

For the molded case circuit breaker (MCCB), select an appropriate product in consideration of the

breaking capacity.

•

For compliance with the UL standard requirements, be sure to perform wiring according to A-4

UL/cUL Standards Cautions on page A-9, which includes the use of UL-compliant Class-J fuses.

•

Tighten the terminal block screws with the specified torque. Weak tightening may result in a short-cir-

cuiting accident or fire. Conversely, overtightening these screws may cause damage to the terminal

block or the inverter.

⚫

3-phase 200-V Class

Maximum

applicable

motor

capacity

[kW]

Power cable,

ground cable

[mm

2

]

*1*2*3

Tightening

torque

[N·m]

*2

Molded

case

circuit

breaker

(MCCB)

*2

*1. The wire size is based on H-IV wire (with a heat resistance of 75°C).

*2. For compliance with the UL standard requirements, be sure to perform wiring according to A-4 UL/cUL Stan-

dards Cautions on page A-9.

*3. The cable is applicable to wiring to the R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, +1, P/+, RB, N/-, and G ( )

terminals.

Recommended Cable Size, Wiring Device, and Crimp Terminal

Loading...

Loading...