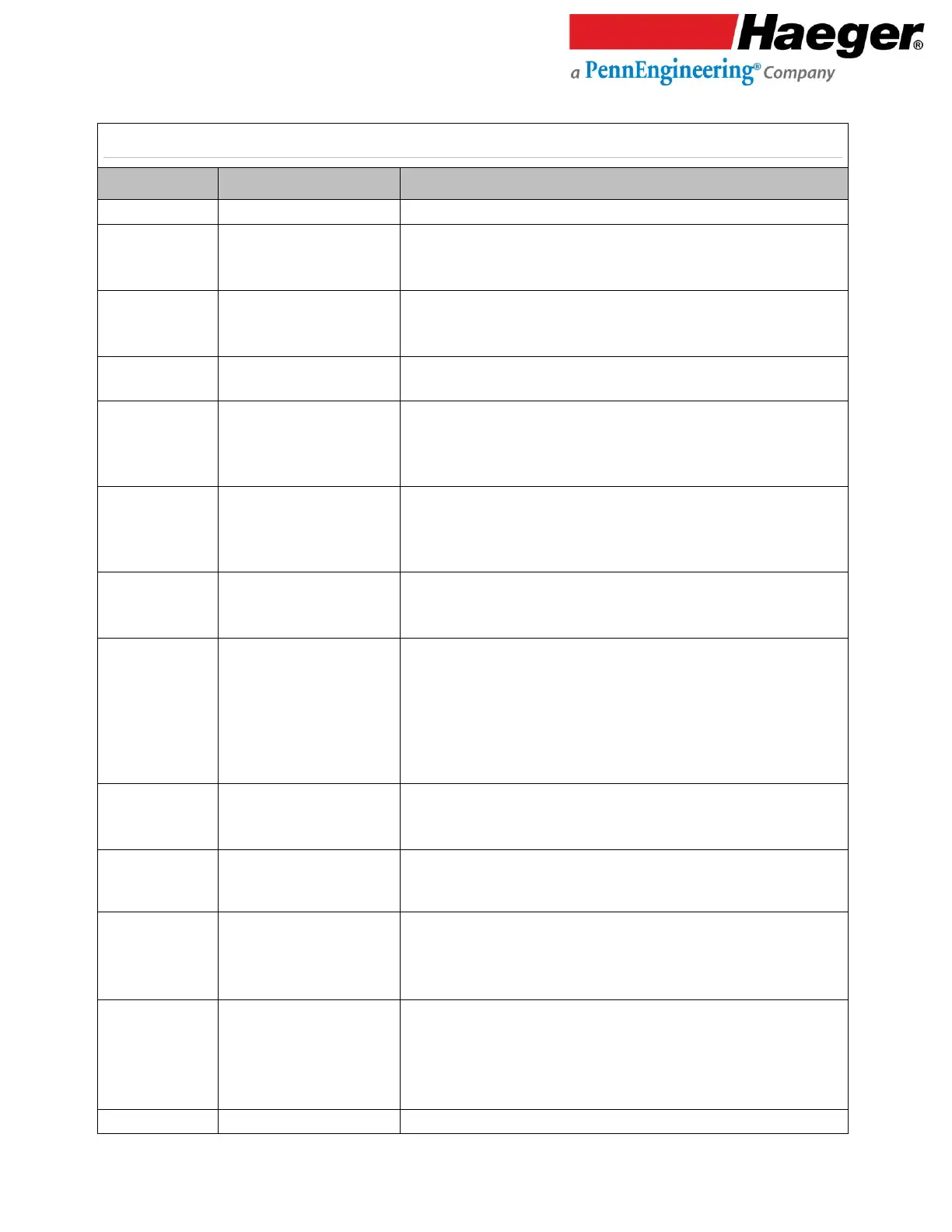

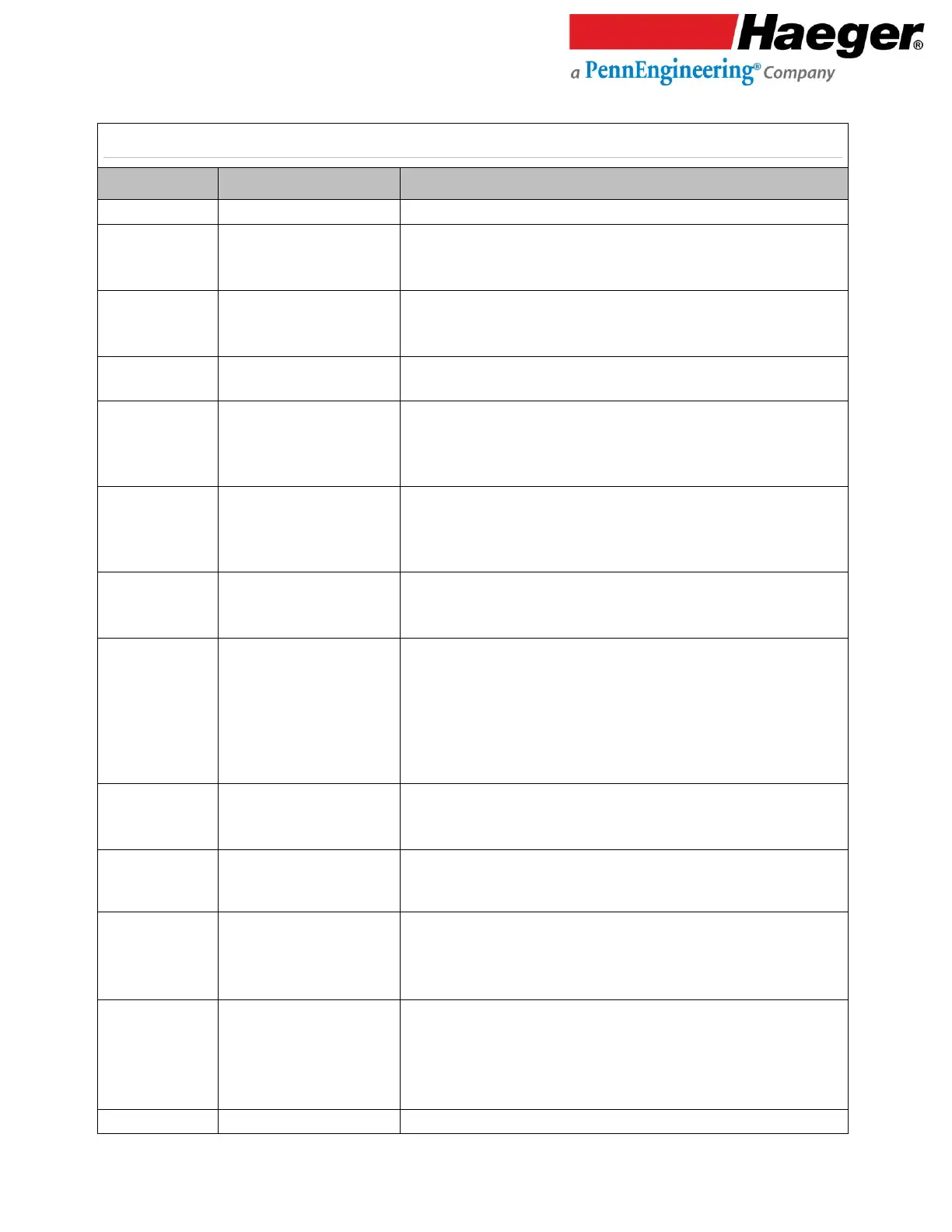

Trouble shooting (continued)

Air blast is wide open

not allowing enough

air to feed fastener.

Check to ensure the air blast is not full open not allowing

enough air to actuate the air cylinder on the singulation

module.

Singulation module air

cylinder is jammed or

not working.

Check the operation of the air cylinder to ensure there is no

binding.

Fastener is jammed in

feed hose.

Check to ensure the feed hose is not kinked and there are

no fasteners jammed in hose.

Air Timer Is turned

down to zero.

Check the Air timer and the air blast settings to ensure they

are properly set to allow enough time to get fastener down

to upper tool.

Nut is feeding

upside down.

Feed Hose is not

turned

180deg.

Check to ensure the feed hose is turned 180deg from the

singulation module to the upper tool holder.

Incorrect orientation

module or singulation

module.

Check to ensure the correct modules are installed for the

fastener you are running.

Ram comes

down and

taps and then

returns up.

No pressure is

built.

Running non-

conductive material

while in the

conductive mode.

Ensure that you are in the right mode for the material you

are running.

Lower tooling or

material is dirty.

Check the condition of the lower tooling and the material. If

the material is dirty this will not allow tooling contact to

take place.

continuity Spring and

pins worn.

Check the condition of the

continuity springs and pins. Also check to ensure the upper

tooling is not binding on the shaft.

Safety switch not

working

Check the condition of the safety switch. Bring the ram

down to mid stroke and lift up on the upper tool. If the ram

does not return up then inspect the safety switch system for

damage.

Machine is sensing

pressure being built.

Check the pressure transducer for proper operation by

turning off the machine and checking the pressure reading

on the administration screen. If pressure shows zero start

machine and take reading. If pressure rises above 30psi turn

off machine and inspect the hydraulic system.

Loading...

Loading...