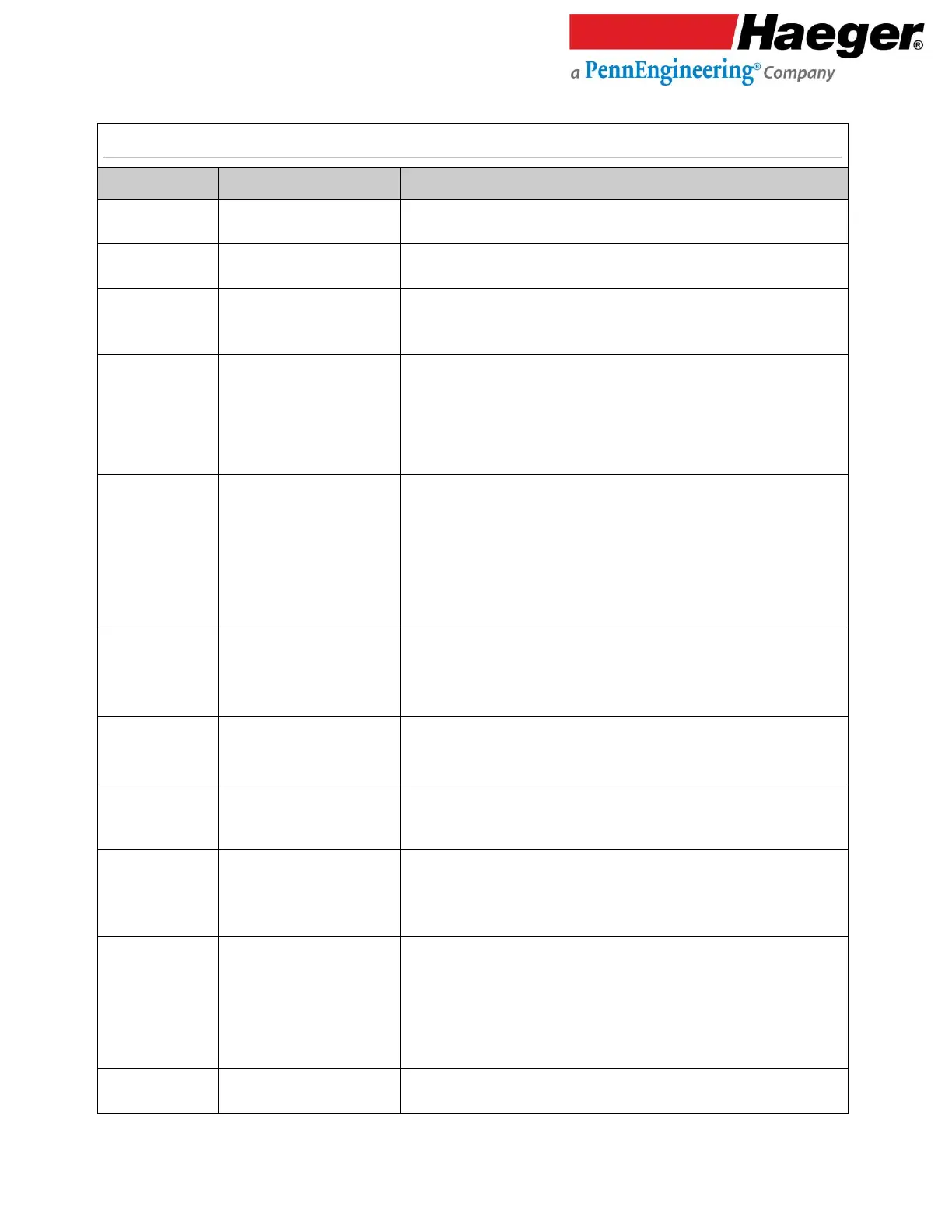

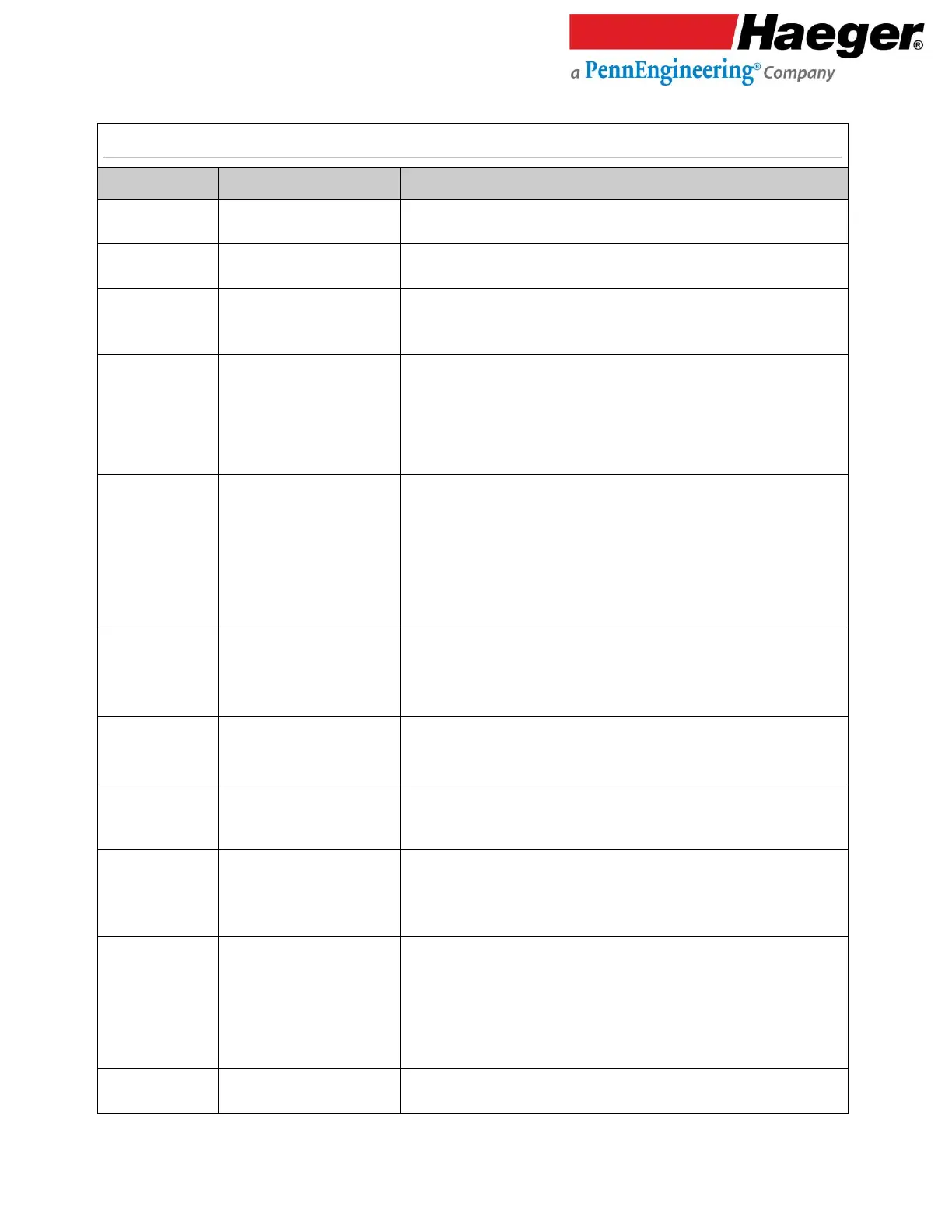

Trouble shooting (continued)

Check the condition of the proportional amplifier.

F3, F6, F10 or F9 Fuses

are burnt.

Relays R3 or R 6 burnt

or not working.

Check to see if relays are cycling. Check contacts for burnt

conditions. If the contacts appear burnt, change out relay.

Ram Comes

Down, builds

pressure, but

will not return

up

Check run screen to ensure it is not in set up mode. This can

also be determined by a yellow run screen.

Pressure is not being

sensed.

Check the pressure reading under the administration/

change plc values. The reading should be no more than 30

at idle. Also check the set point to ensure it is at 60 to 90. If

the set point is not correct, adjust to 90. If there is no

pressure being shown at idle, Check the wiring and plug

going to the pressure transducer for damage or loose

connections.

While watching the pressure screen, operate machine and

verify the pressure goes above the set point. Example: If

pressure only reaches 60 and set point is at

90, adjust set point to 55.

Continuously

getting TPS

errors.

TPS sensitivity set to

low.

Reset TPS using the part and fastener for the job.

TPS set at high

pressure.

On older machines - set the TPS using min pressure. On high

speed machines it does not matter what force is selected.

Continuity pins and

spring worn causing

incorrect set

point.

Check the springs and pins in the upper tool holder for

damage or collapsed springs.

This error will come up when too much information had been

entered on any given line or too many characters. Example

would be TPS setting containing astrics. Look for this

occurrence on all information windows in the run screen,

admin screen, password screen, program screens.

If you cannot find the problem, reload the software and this

will reset default values.

Loading...

Loading...