3.40

ENGINE

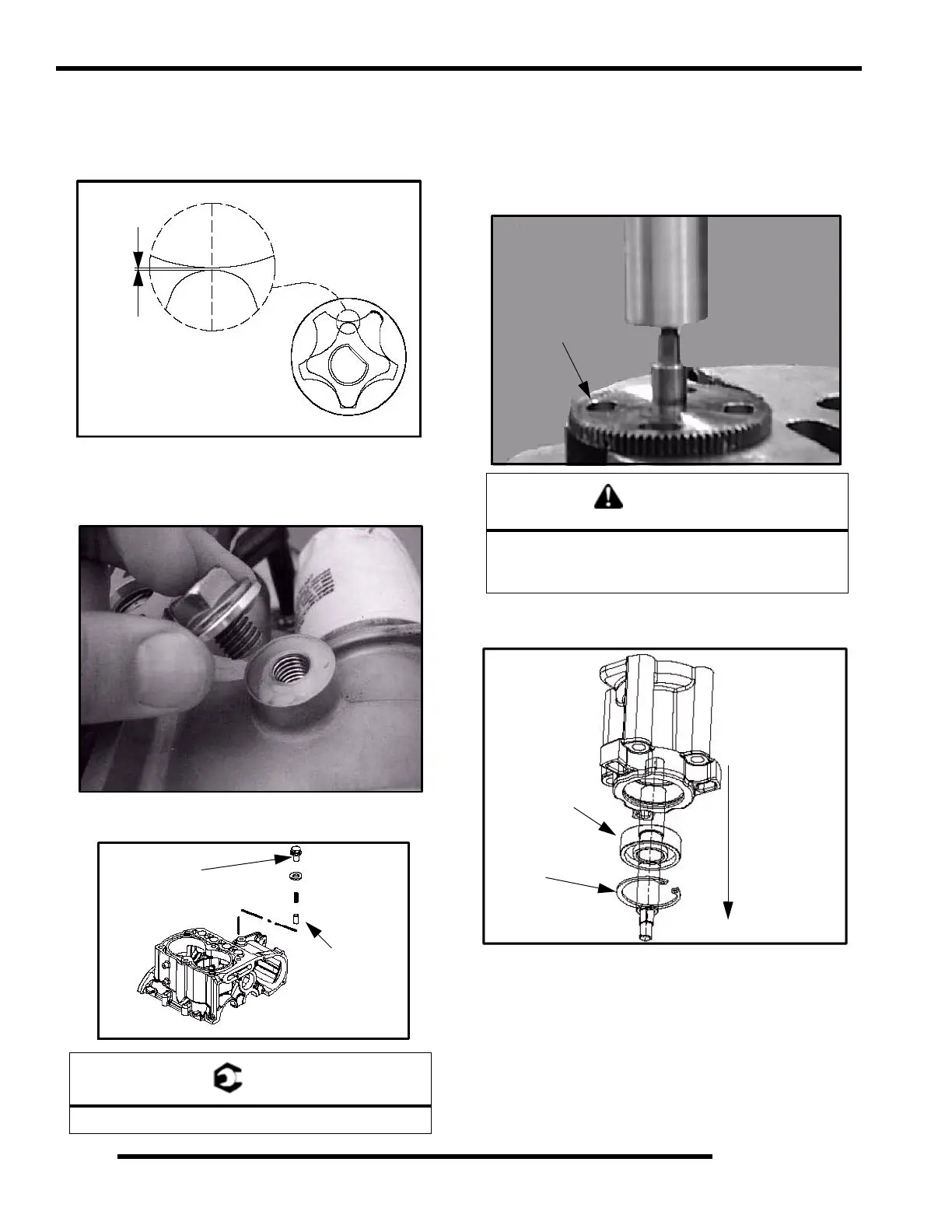

28. Use a feeler gauge to measure the clearance between the

two rotors. Measure the gap between the two rotor tips as

shown below. The clearance should not exceed 0.006"

(0.15 mm).

29. Remove the oil pressure relief. The oil pressure relief

consists of a bolt, washer, spring, and valve (dowel).

Inspect the valve (dowel) for signs of possible obstructions.

Use compressed air to blow out any debris.

30. Reinstall the valve (dowel chamfered end first). Install the

spring, washer, and bolt. Torque to specification .

NOTE: Be sure to place the tapered end of the valve

(dowel) in first. If the valve is installed incorrectly,

oil pressure and oil priming problems will occur.

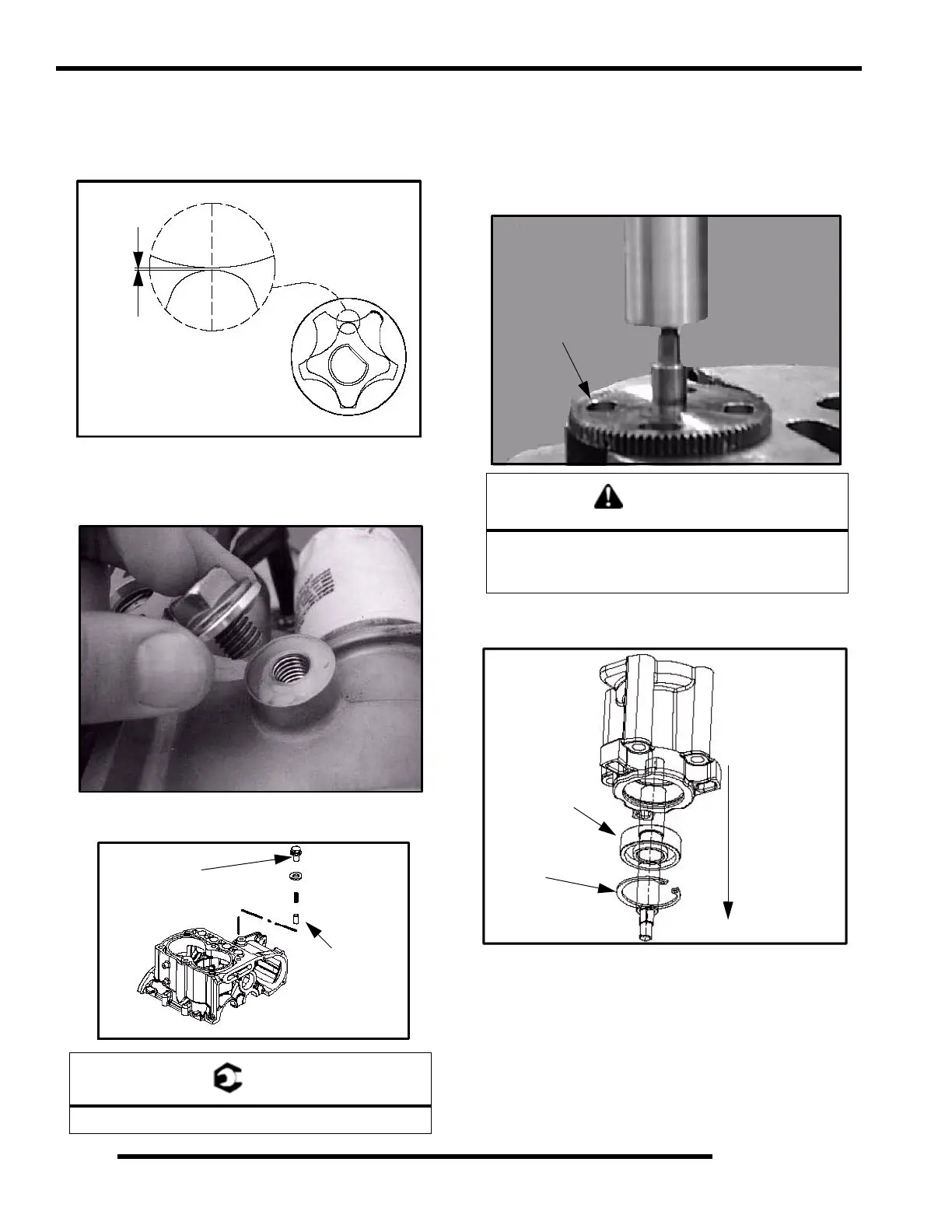

31. Carefully press the gear off the assembly while supporting

the housing assembly.

32. Remove the snap ring from the assembly. Place the housing

in a support and press out the bearing/shaft assembly.

= T

22 2 ft. lbs. (30 3 Nm)

0.006” (0.15 mm)

Max Tip Clearance

22 22 2 ft. lbs.

(30 3 Nm).

Chamfer

End First

CAUTION

Wear appropriate safety gear during this procedure.

Protective gloves, clothing and eyewear are

required.

Press Off Gear

Press Out shaft

and bearing

assembly.

Bearing

Retaining Ring

Loading...

Loading...