9.27

Chassis

9

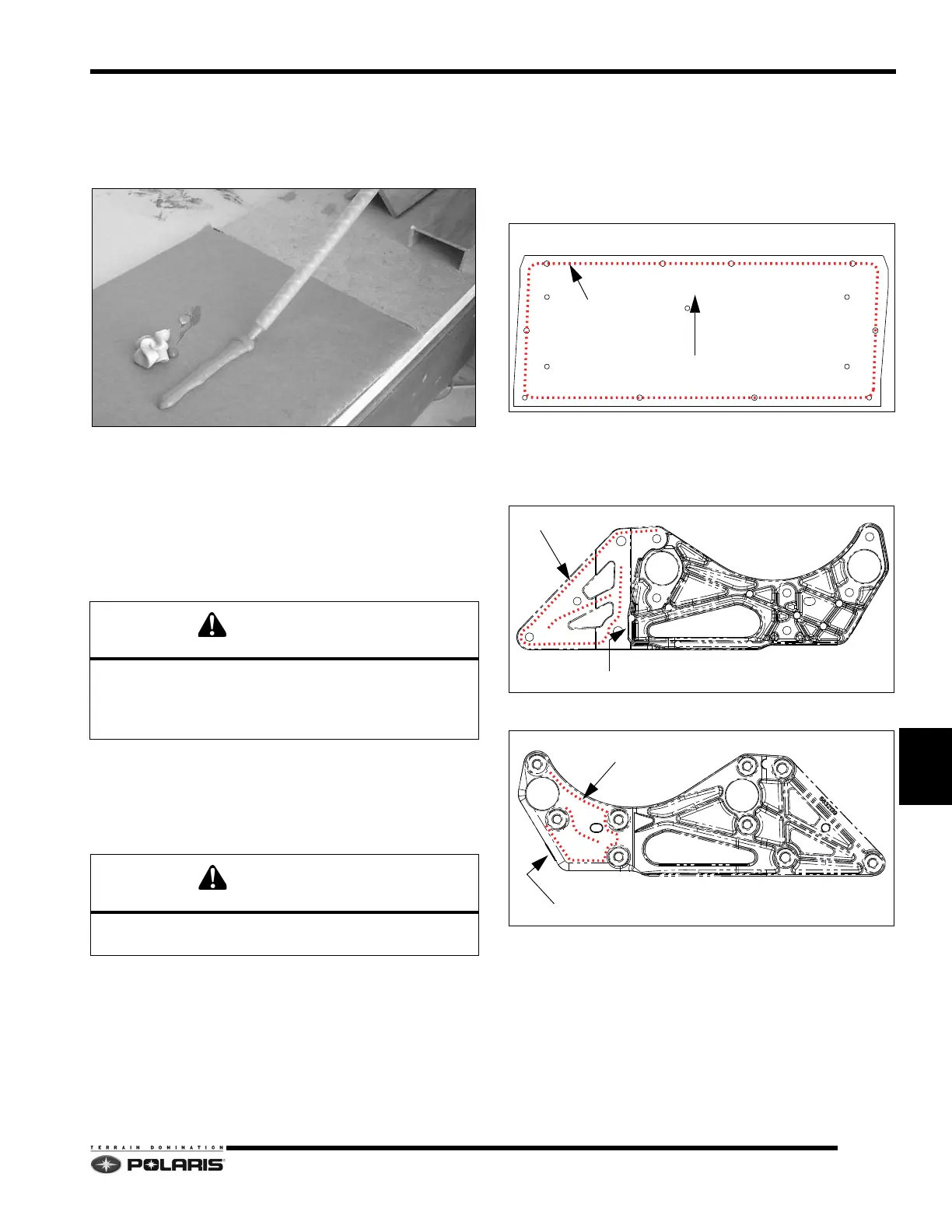

3. While holding the mixer needle over a piece of scrap

material, slowly compress the caulk gun trigger to fill

the mixer needle. The needle will automatically mix

and dispense the correct volumetric ratio of adhesive

and accelerator.

4. Continue squeezing the trigger until a needle’s length

o

f adhesive is expelled.

5. Quickly apply a 4mm bead of adhesive to the

comp

onent as shown on the following pages. Apply

adhesive to one component at a time.

6. Carefully install the component and torque the

fastene

rs to specification immediately. Do not break

the bond once the components are mated.

7. When not using the adhesive, leave the mixer needle

at

tached to the cartridge.

8. If the needle has sat idle for any amount of time,

simply re

move the needle, and repeat steps 2 through

4 to apply adhesive to additional components.

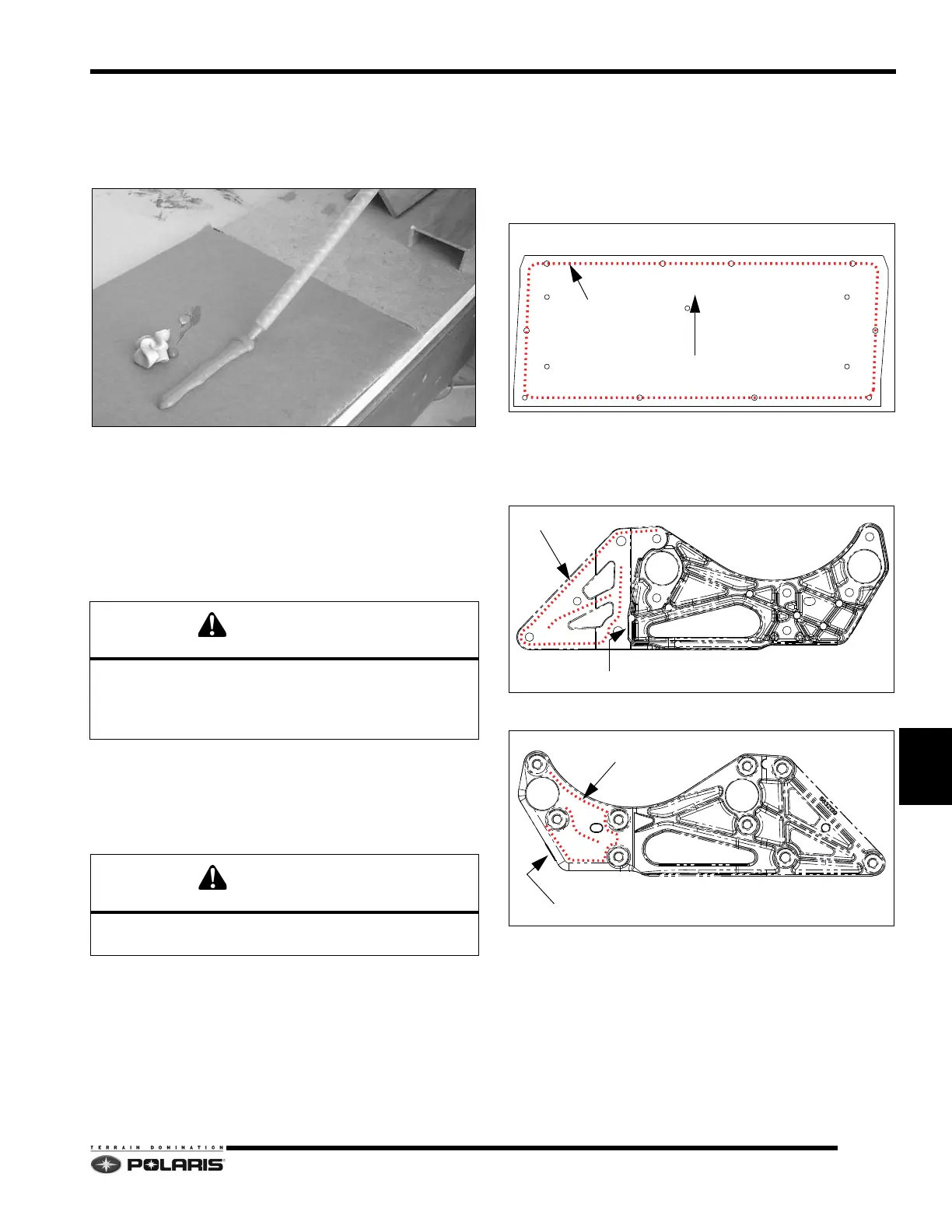

Adhesive Application Patterns

Reference the following illustrations showing the exact

patterns for each bonded component when applying the

adhesive.

BULKHEAD FLOOR

LH (PTO) SIDE BRACE

(BULKHEAD MATING SURFACE)

(FRONT CLIP MATING SURFACE)

The bonded parts can be repositioned by gently sliding

them into position. Never pull the parts apart. Doing so

will introduce air gaps and will require removing the

parts, and removing all adhesive.

Do not manually mix the adhesive and accelerator.

Always use a mixing needle to apply the adhesive.

ADHESIVE

LINE

APPLY ADHESIVE TO COOLER/PLATE MATING SURFACE

ADHESIVE

LINE

APPLY SMALL AMOUNT OF ADHESIVE HERE

Loading...

Loading...