44

Chapter 3 Troubleshooting Display Messages

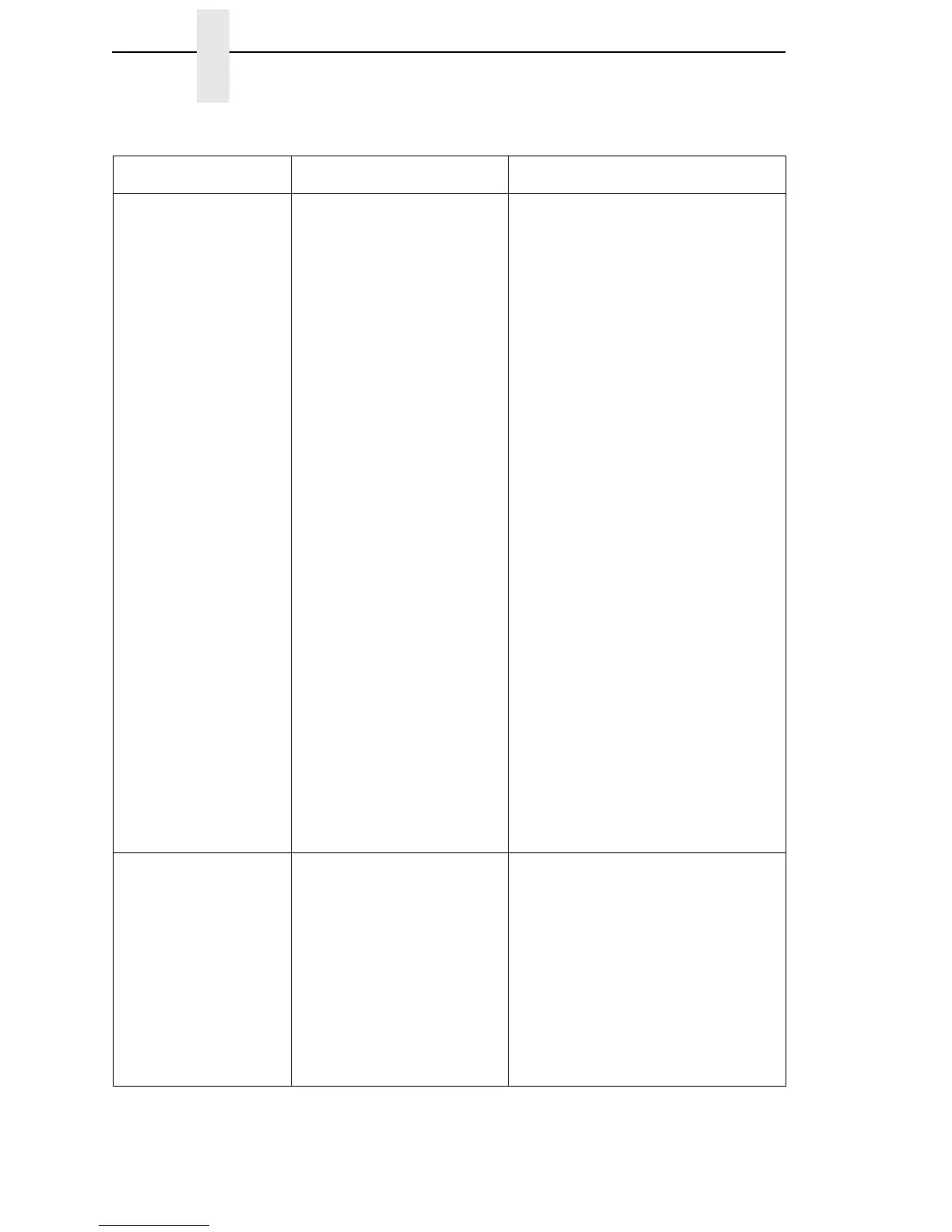

34 RIBBON STALL

TIMEOUT

In the CT emulation with a

coax interface, the ribbon

has not moved for 10

minutes after CLEAR was

pressed to clear the ribbon

drive fault.

1. Set the forms thickness lever to

match the thickness of the paper

being used, but not too tightly.

2. Inspect the ribbon guides for ink

buildup, which can inhibit ribbon

movement. Clean the printer.

3. Inspect the hammer bank cover/

ribbon mask for bending or

damage. Replace if bent or

damaged.

4. Check the platen gap: if too

small, it can inhibit ribbon

movement. Adjust the platen gap.

5. Power off the printer. Remove the

paper path or pedestal top cover.

Disconnect P106 and P107 from

the controller board. Check the

resistance of LRIB M in P106 and

RRIB M in P107. (Refer to the

Main Wire Harness Test Tables

in Appendix A.) If ribbon motor

resistance is not correct, replace

the motor. If the resistance is

correct, disconnect the ribbon

motor cables from the motors and

check continuity. Replace a cable

if it fails the continuity test.

6. Power on the printer. Run a

diagnostic print test. If the

RIBBON STALL message

appears, replace the controller

board. Record the message and

return it with the defective board.

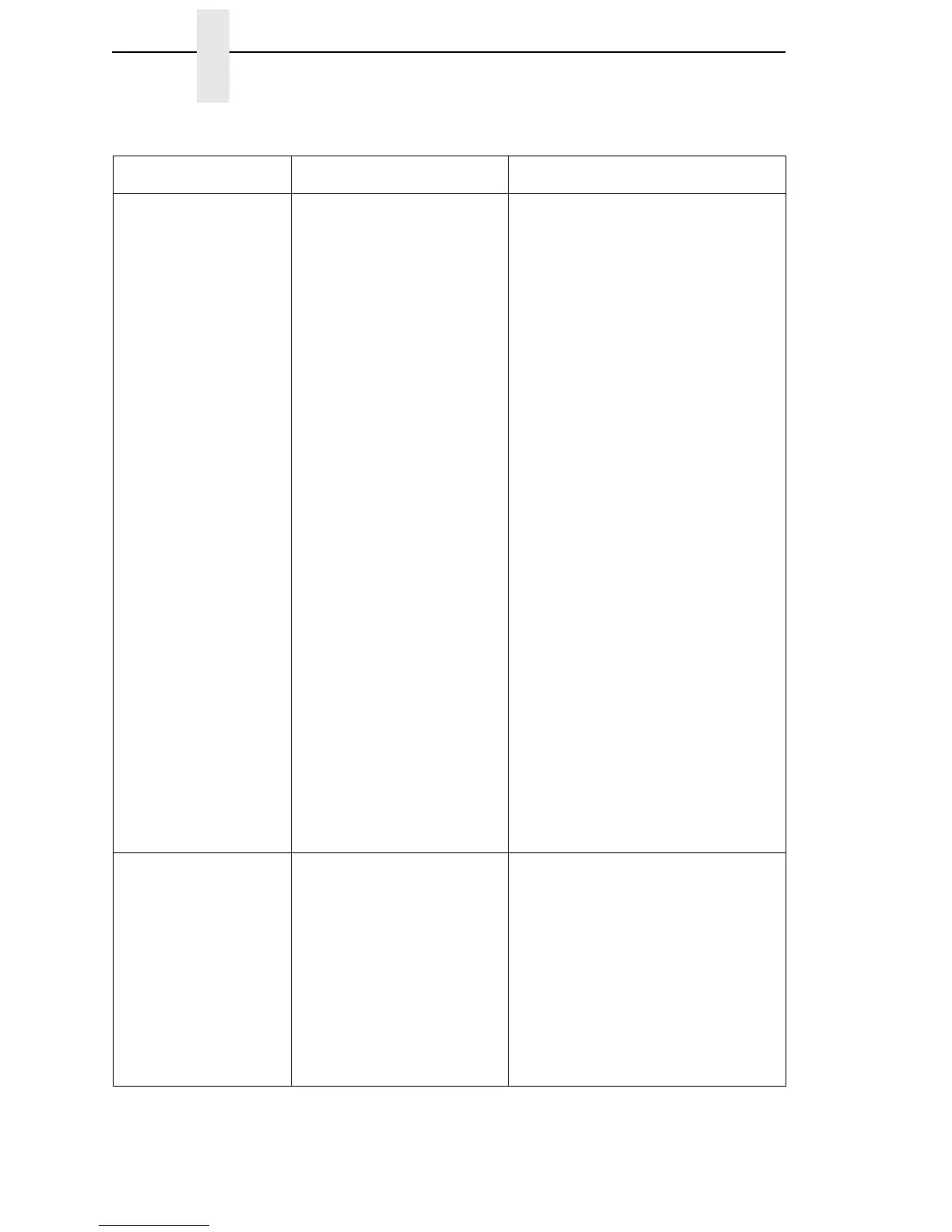

48V CIRCUIT*

See Manual

The power supply is not

generating a proper 48 Volts,

or the controller board is not

detecting a 48 Volt output

from the power supply

board.

1. Make sure the power supply

board is correctly connected to

the controller board.

2. Power on the printer. If the

message appears, replace the

power supply.

3. Power on the printer. If the

message appears, replace the

controller board. Record the

message and return it with the

defective board.

Table 2. Message List

Message Explanation Solution

Loading...

Loading...