15. SAMPLES PREPARATION

This section of user manual contains information about obtaining optimum test results during

drying process. There are hints for selection of appropriate drying parameters for various

materials and substances.

15.1. Moisture Content Measurement Principle for Moisture Analyzer

Measurement of sample moisture content is carried out by determining the loss of sample

mass during heating (evaporation).

MAX2 moisture analyzer is comprised of two elements: a precision balance and a drying

chamber. Compared to standard moisture content determining methods, the measurement

with application of RADWAG moisture analyzer is much quicker and does not require

additional mathematical calculations (a result of moisture content is previewed on an

ongoing basis during product testing process).

Independently on moisture content determining method, the measurement accuracy is highly

influenced by means of sample preparation and selection of testing parameters, such as:

• sample size

• sample type

• drying temperature

• drying time

In practice, the measurement accuracy is not as important as the speed of obtaining

measurement result (control over technological process). Thus, heating a sample (with

application of a halogen filament) carried out by a moisture analyzer, makes the

measurement process very time efficient and short. Measurement speed can be additionally

increased by appropriate adjusting moisture analyzer’s parameters depending on tested

substances.

Optimum temperature and drying time depend on sample type and size, and anticipated

measuring accuracy. Selection of drying parameters can only be carried out on basis of test

measurements.

15.2. Sampling and Preparation

Sample features, its preparation and size are very important factors influencing the speed

and accuracy of measurement process.

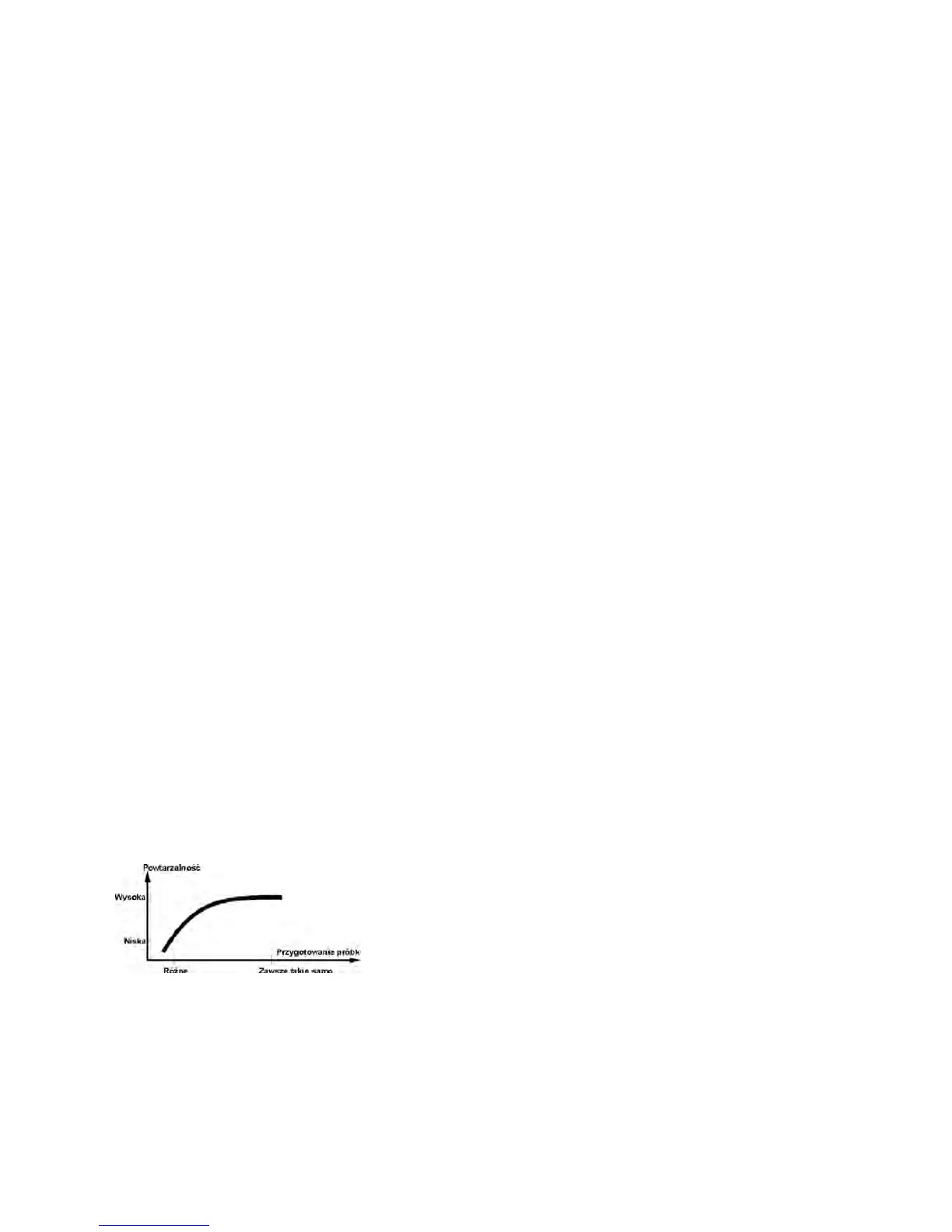

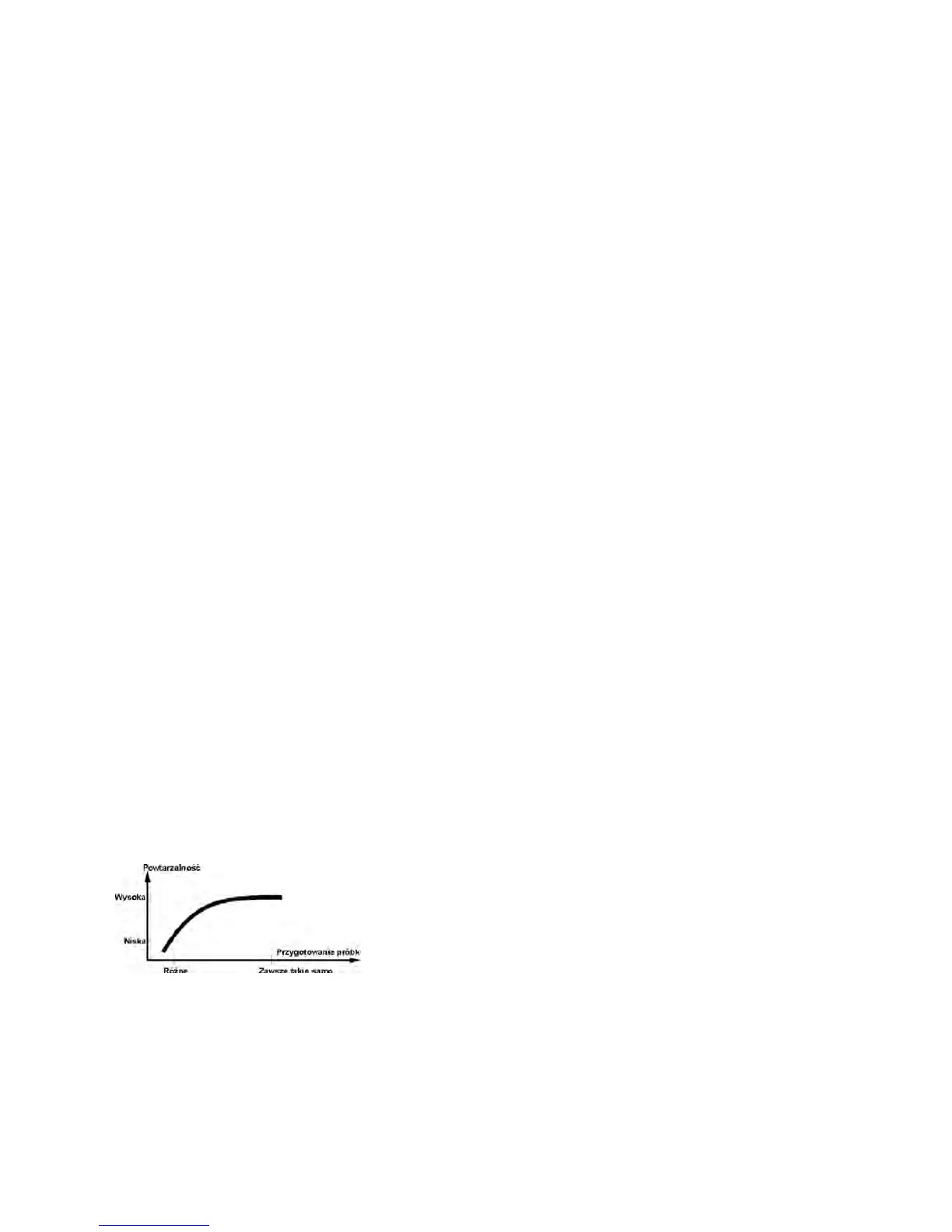

Means of sampling and preparation are extremely important for repeatability of measurement

results, as a sample should be a representative part of tested substance.

Final measurement result is vastly conditioned by precise and considered sample

preparation. A sample used for analysis has to represent the total structure of tested

material. Sampling process should determine: sampling means, sample disintegrating,

particle size after disintegration, sample uniformity and other. The sampling process has to

be carried out as quickly as possible, so that a sample does not lose or absorb moisture from

surrounding area.

Applied sampling standards should match individual operator needs and requirements of

tested material, its consistence and sample size.

Loading...

Loading...