• selecting appropriate finish criterion, which enables to finish the drying process in an

optimum point of the drying step,

• selecting constant drying time usually ensures correct and repeatable results,

• maintaining constant sample start mass.

17. DRYING

DRYING mode enables to determine moisture content of a given sample. The moisture

content value is obtained via evaporation of moisture from sample placed inside the drying

chamber. The result is calculated automatically (and displayed) in real time, the calculation is

made on the basis of sample mass at the beginning, in the course, and at the end of the

process.

Procedure for activation of Drying mode:

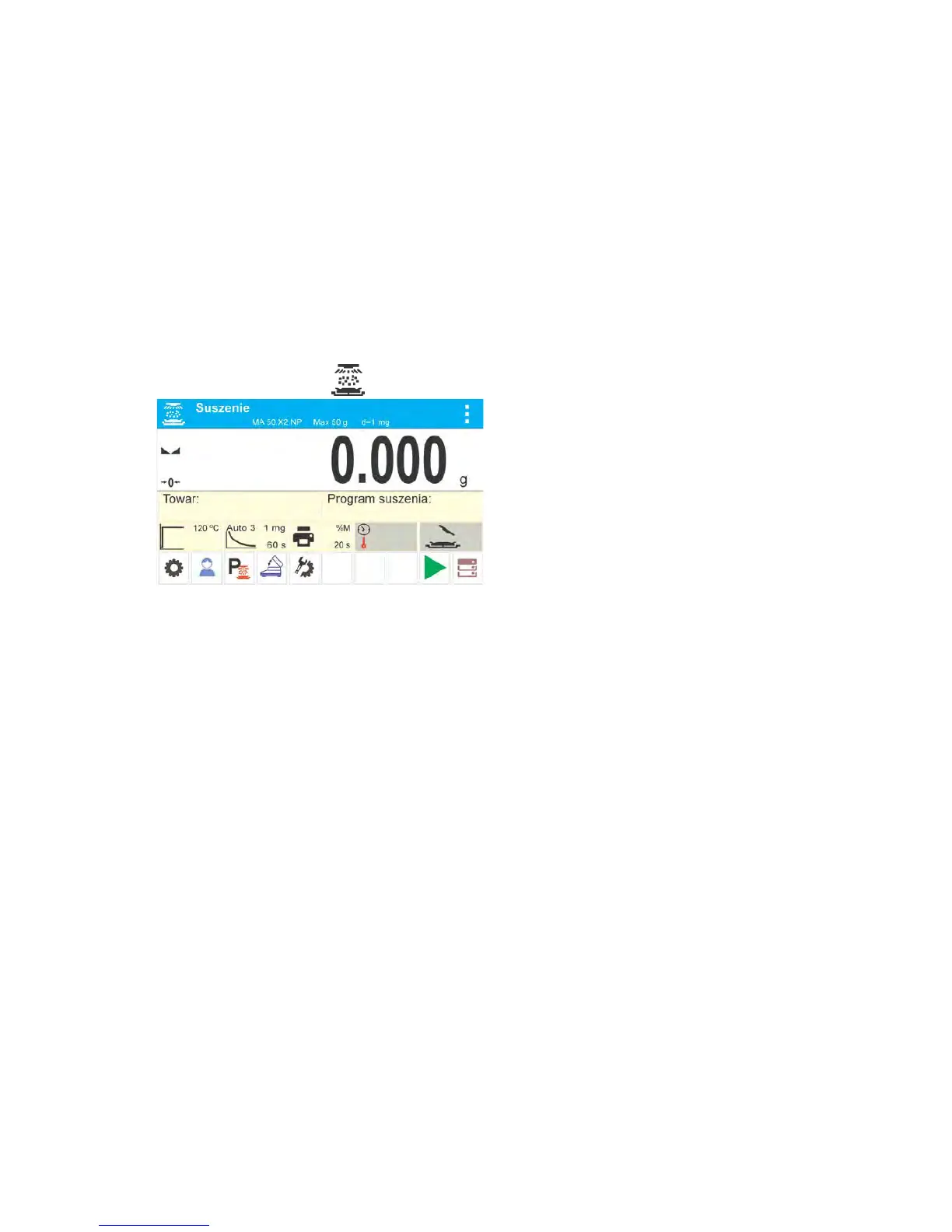

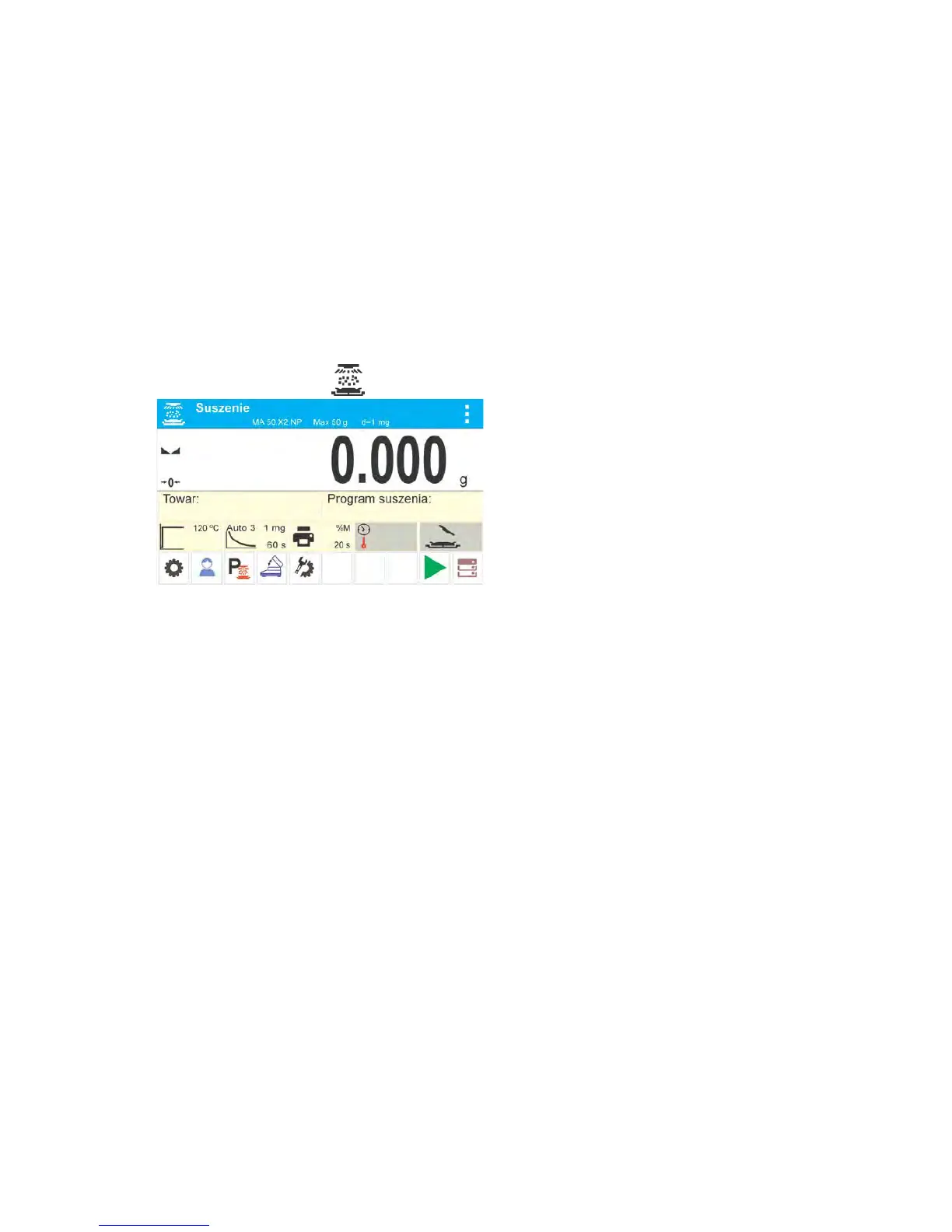

• Select <Drying> mode, the home screen is displayed automatically, wherein the top bar

of the screen features pictogram.

Info field provides the following information:

• Product

• Drying program

• Drying profile and drying temperature value

• Finish mode

• Printout parameters

• Info field displaying (in the course of drying) time and drying temperature values

• Info field displaying chamber status

• Buttons: parameters, user, drying program, open/close cover, drying mode settings,

start, databases

17.1. Mode Related Settings

The supplementary settings enable you to adjust the working mode to your needs and

requirements.

Drying profile

Parameter enabling you to select respective drying profile and set drying temperature.

Finish mode

Parameter enabling you to select respective finish mode and set its parameters.

Printout parameters

Parameter enabling you to set the drying process unit for both the display and the printout,

and measurement result printout interval during drying.

Loading...

Loading...